A mechanical locking nut connection anti-loosening structure

A mechanical lock and nut technology, which is applied in the direction of connecting components, nuts, mechanical equipment, etc., to achieve reliable anti-loosening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

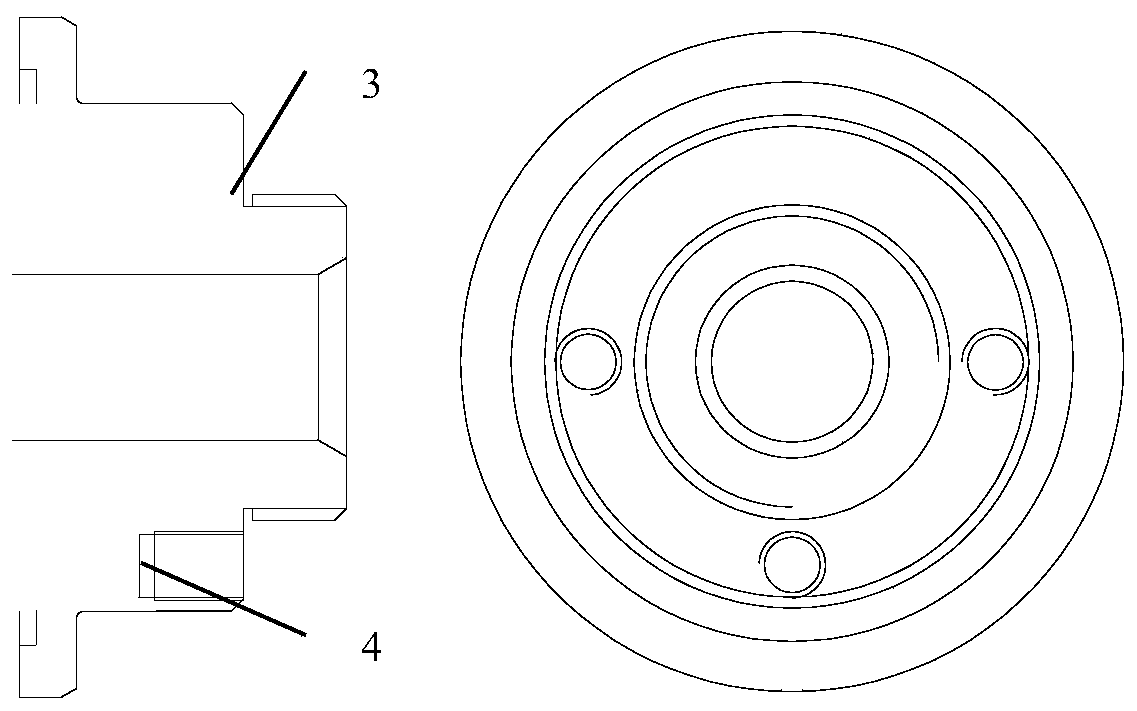

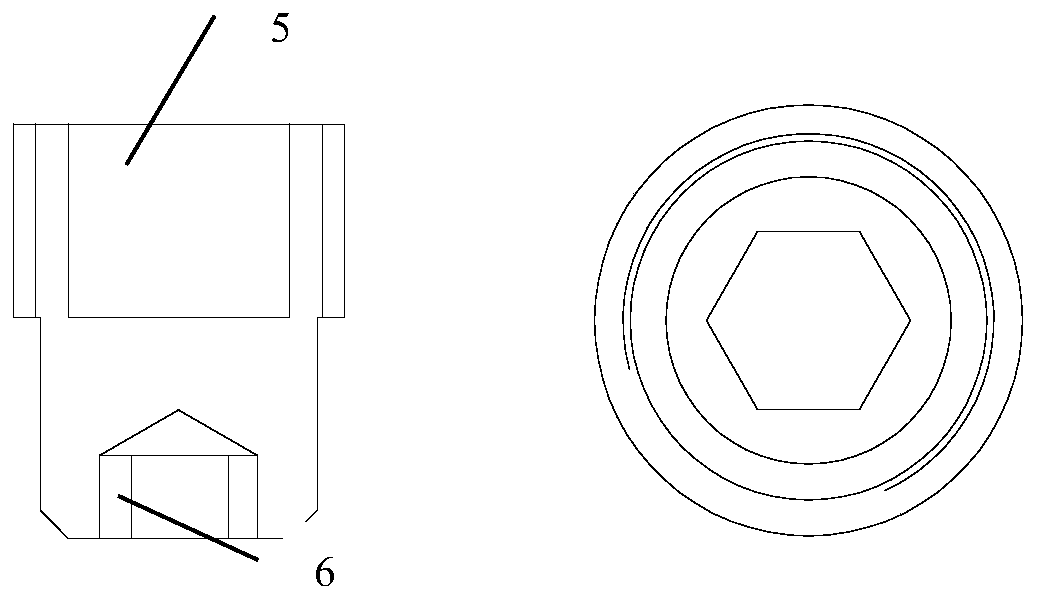

[0022] The present invention will be described in detail below with reference to the accompanying drawings and the embodiments thereof, but the protection scope of the present invention is not limited to the scope described in the embodiments.

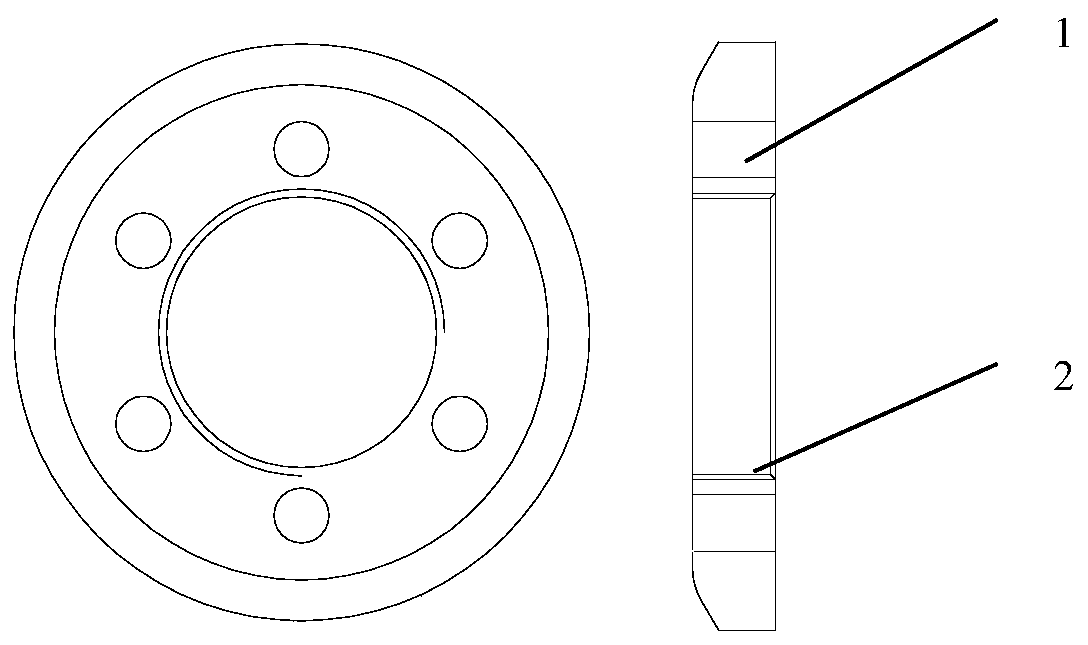

[0023] see Figure 1-6 , The nut structure in this embodiment includes three parts: a nut, a screw rod and a small screw.

[0024] Structure and composition

[0025] 1.1 Nut

[0026] figure 1 It is a schematic diagram of the nut structure of the present invention, and a certain number of evenly distributed through holes are drilled at corresponding positions on the nut. The left side of the figure is the front view of the nut, and the right side is the left side view. As can be seen from the front view in the figure, the center of the nut has a threaded hole, and there is an internal thread 2 in the threaded hole. The outside of the threaded hole of the nut has an annular nut body, and several through holes 1 are distributed along...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com