Robot vision practical training platform

A robot vision and training platform technology, applied in instruments, educational appliances, teaching models, etc., can solve the problems of low workpiece recognition accuracy and incomplete image acquisition, and achieve the effect of improving the visual recognition effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

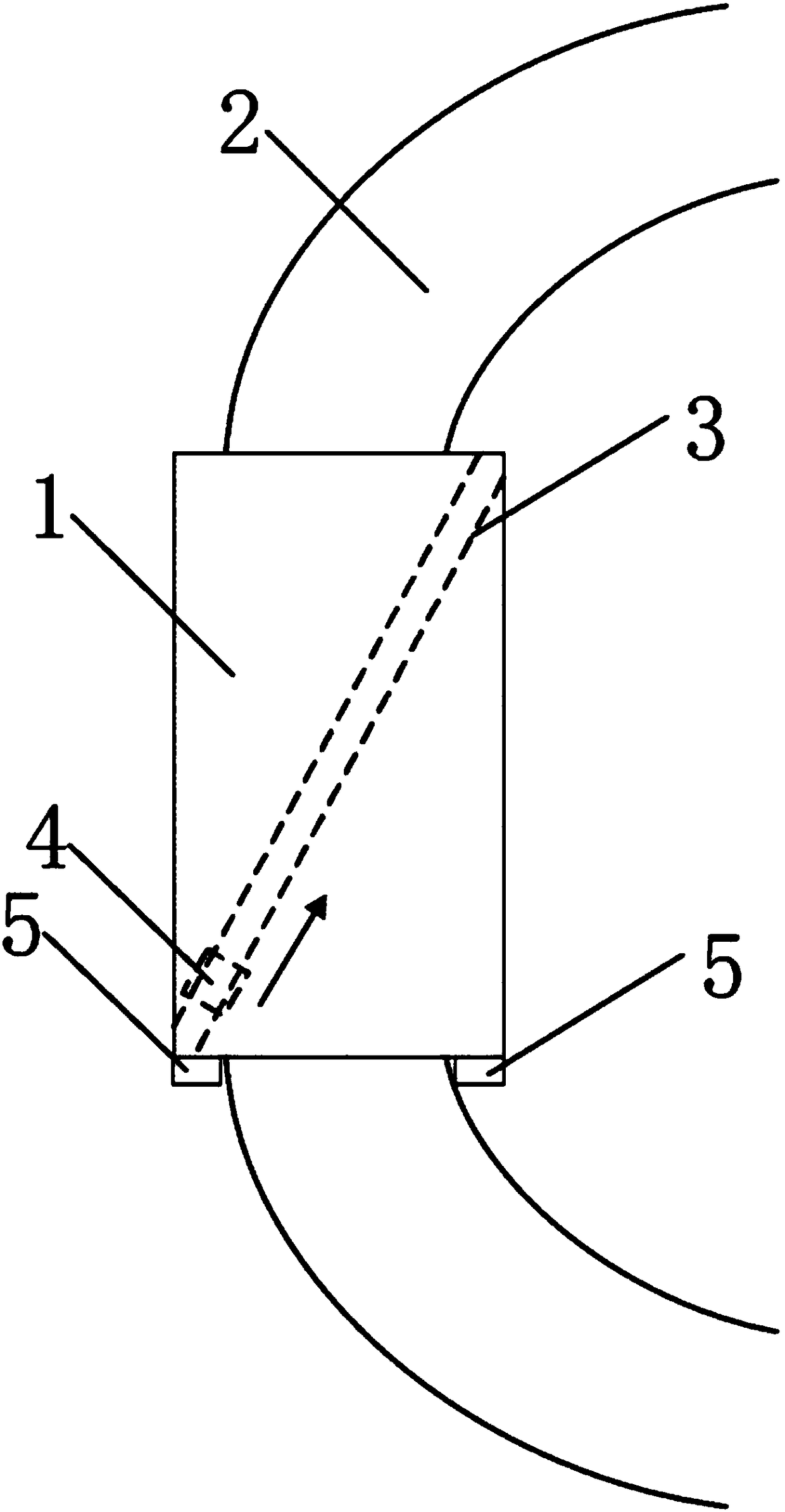

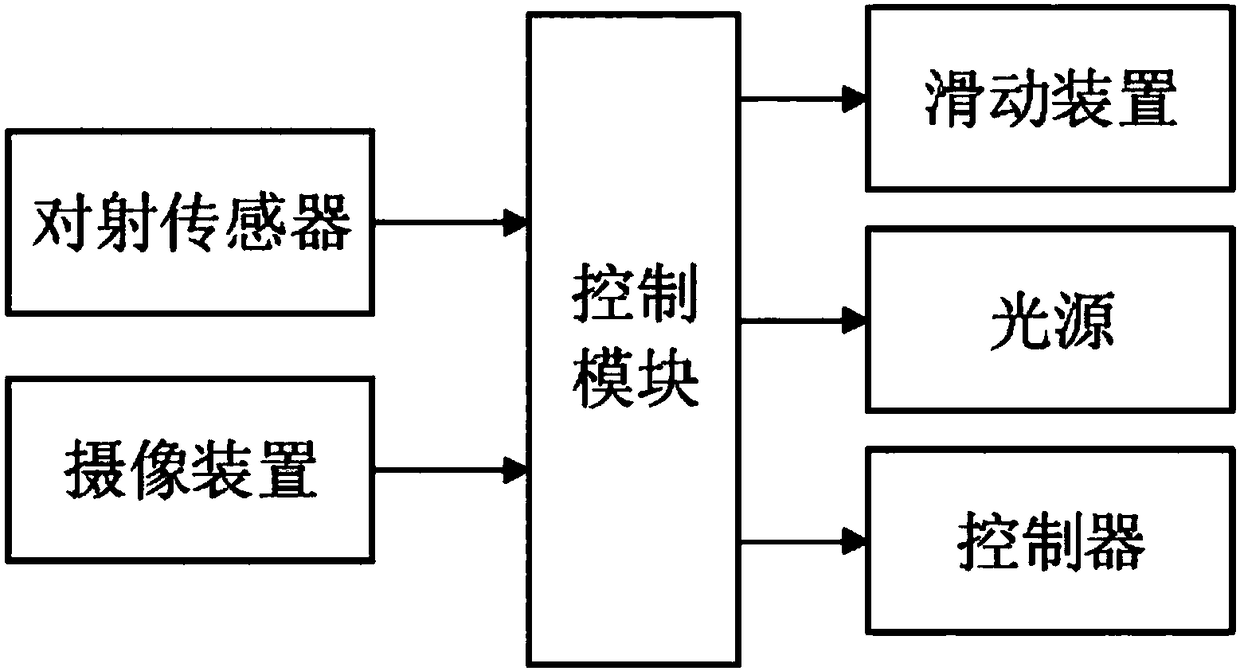

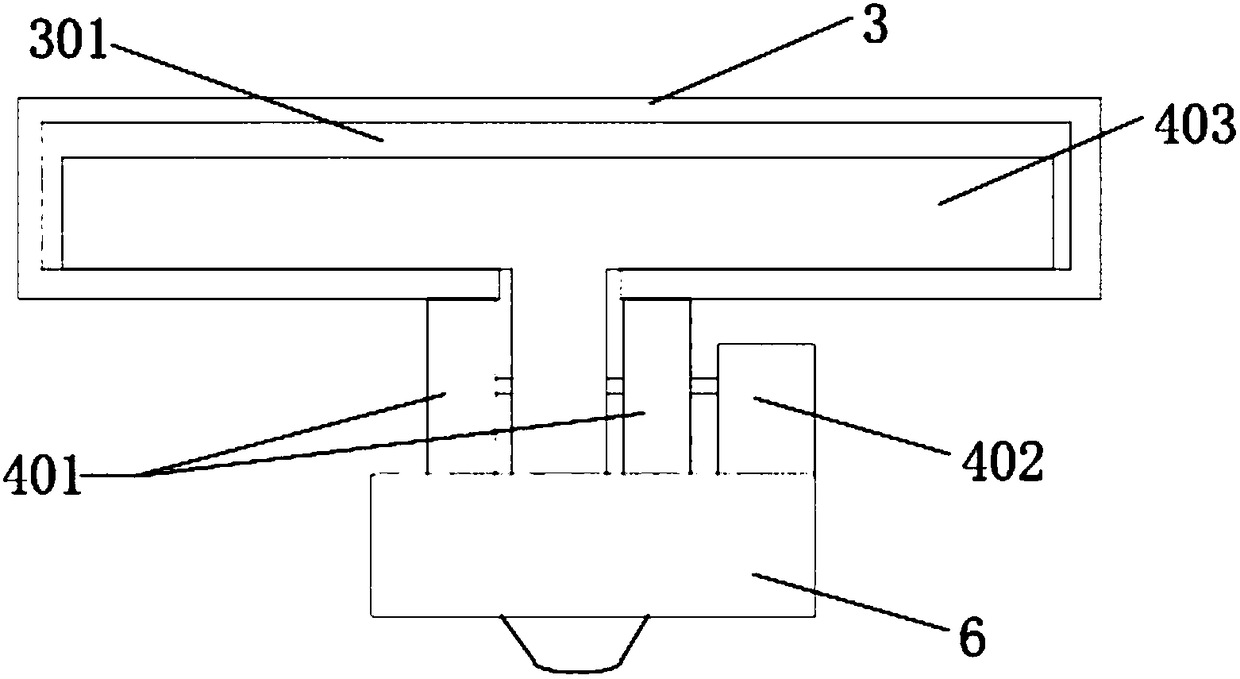

[0013] like figure 1 As shown, a kind of robot vision training platform of the present invention comprises: circular conveying mechanism and machine vision system; Said machine vision system comprises: control module, C-shaped bracket 1 (particularly semicircle) and camera device 6, The notch of this C-shaped support 1 is downwardly straddled on a transmission belt 2 of the circular conveying mechanism, and is positioned at the inner wall of the C-shaped support 1, and the diagonal line of the C-shaped support is provided with an arc-shaped guide rail 3, and the camera device 6 through a sliding device 4 ( figure 1 The middle camera device 6 is blocked by th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap