Moving storage robot

A robot and warehousing technology, applied in the field of robots, can solve problems such as loss of economic significance, lack of replenishment function, inconsistent rectangular space, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

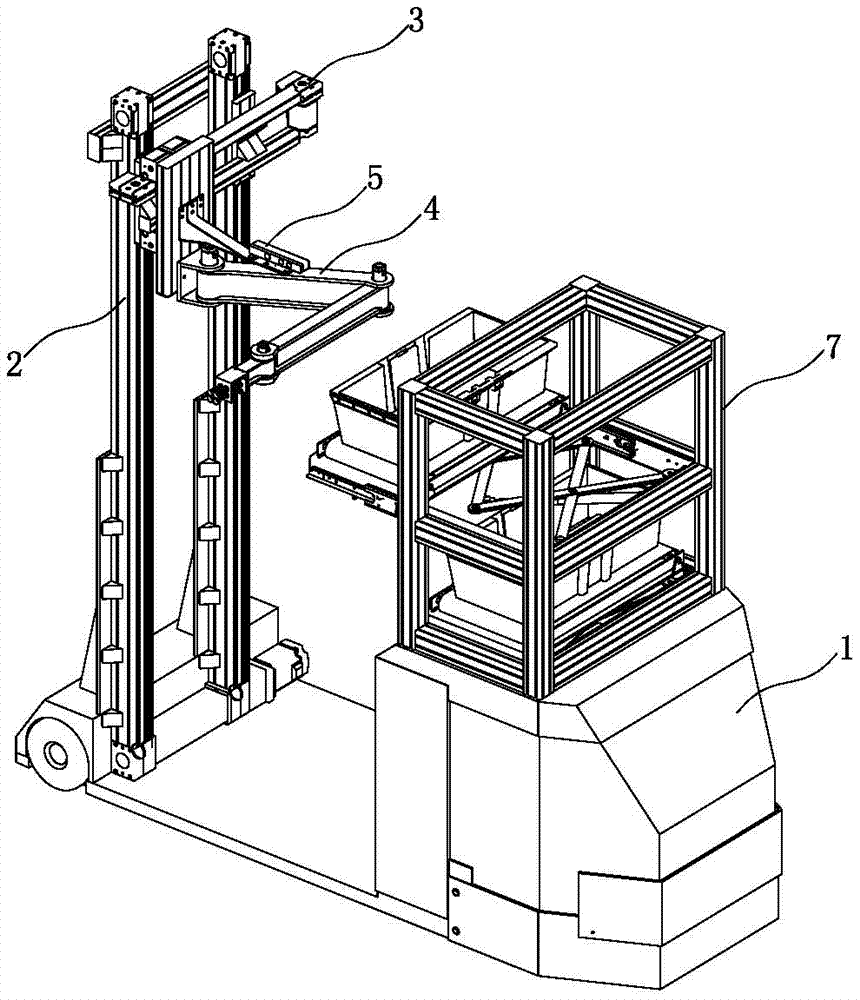

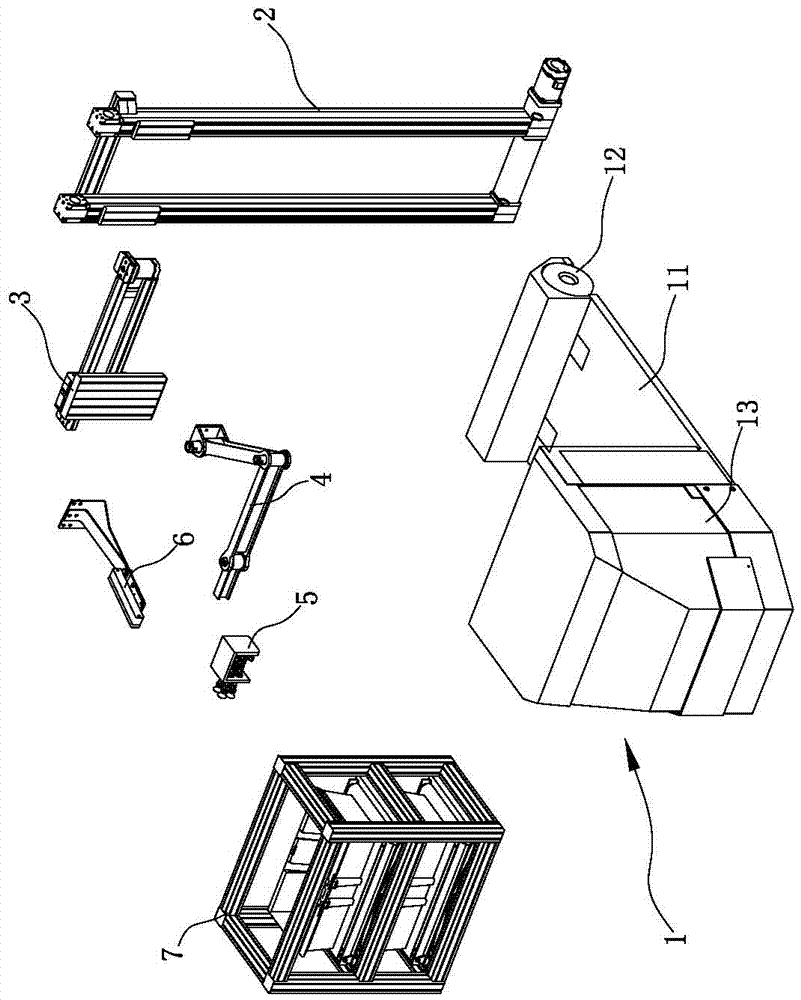

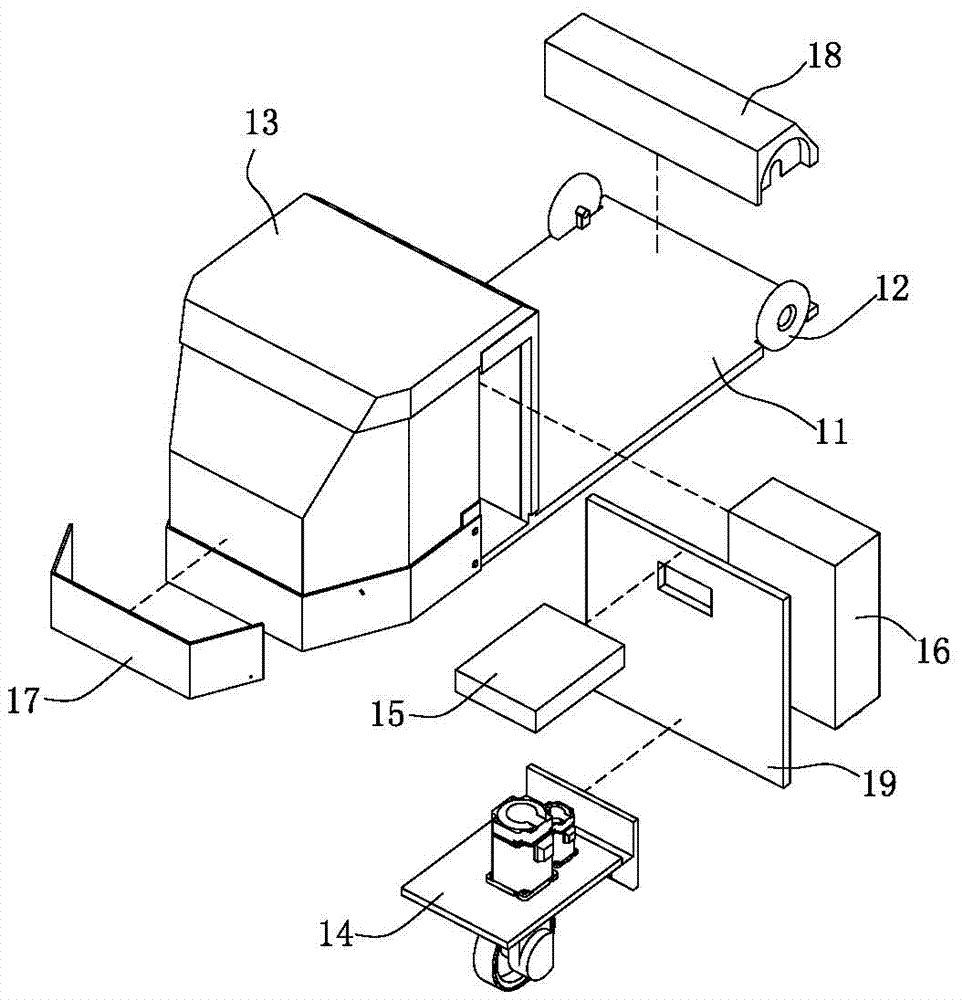

[0045] Such as figure 1 As shown, a kind of mobile storage robot disclosed by the present invention includes:

[0046] An automatic guided vehicle 1 for supporting and driving the overall walking of the robot;

[0047] The double-column lifting device 2 installed at the rear end of the middle part of the automatic guided vehicle;

[0048] The lateral moving device 3 installed on the double-column lifting device, the lateral moving device 3 can be driven by the double-column lifting device 2 to move vertically;

[0049] The three-joint manipulator 4 and the machine vision system 5 installed on the lateral movement device 3, the three-joint manipulator 4 and the machine vision system 5 can be driven by the lateral movement device 3 to move horizontally left and right, and can follow the lateral movement device 3 Vertical lifting movement driven by the double column lifting device 2;

[0050] An end effector 6 installed at the end of the three-joint manipulator 4, the end effe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap