An ultra-high-speed palletizing and handling robot for intelligent logistics

A handling robot and intelligent logistics technology, applied in the field of handling robots, can solve the problems of neglecting the detection of the cross-sectional size, shape and weight of objects, and unable to provide classification reference information for staff.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

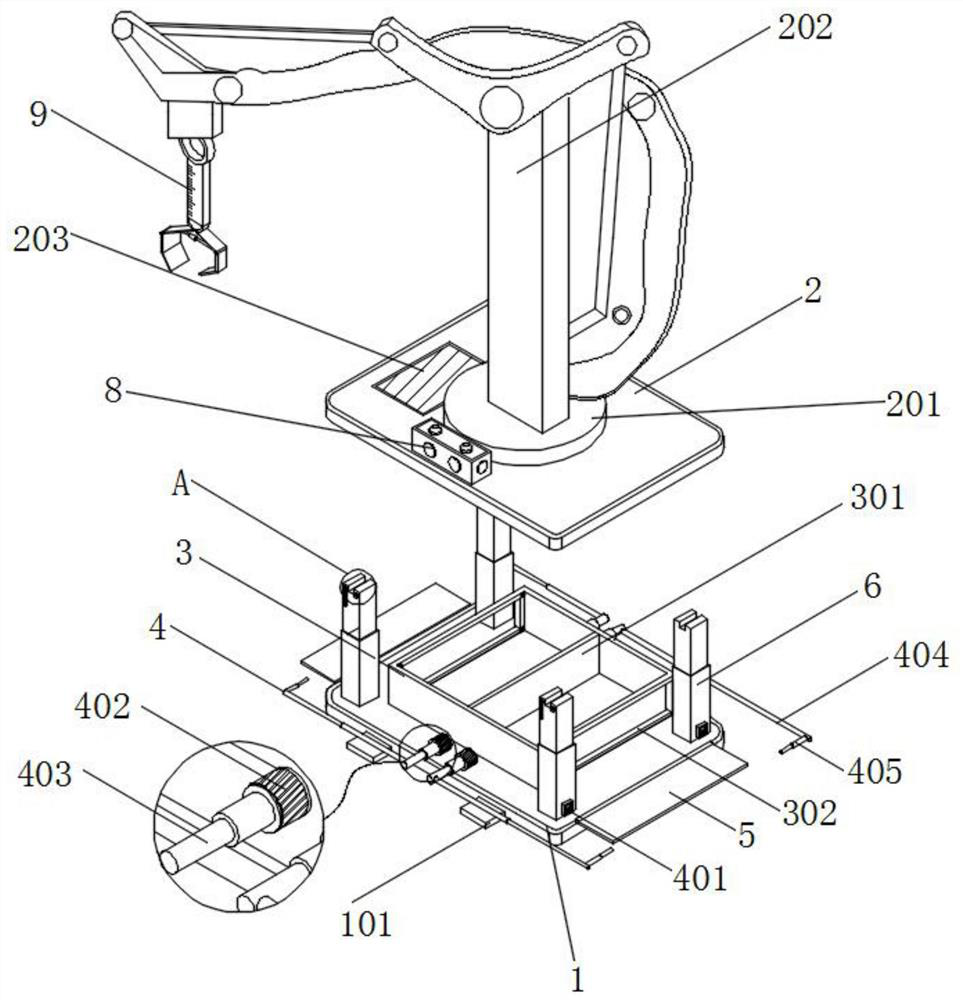

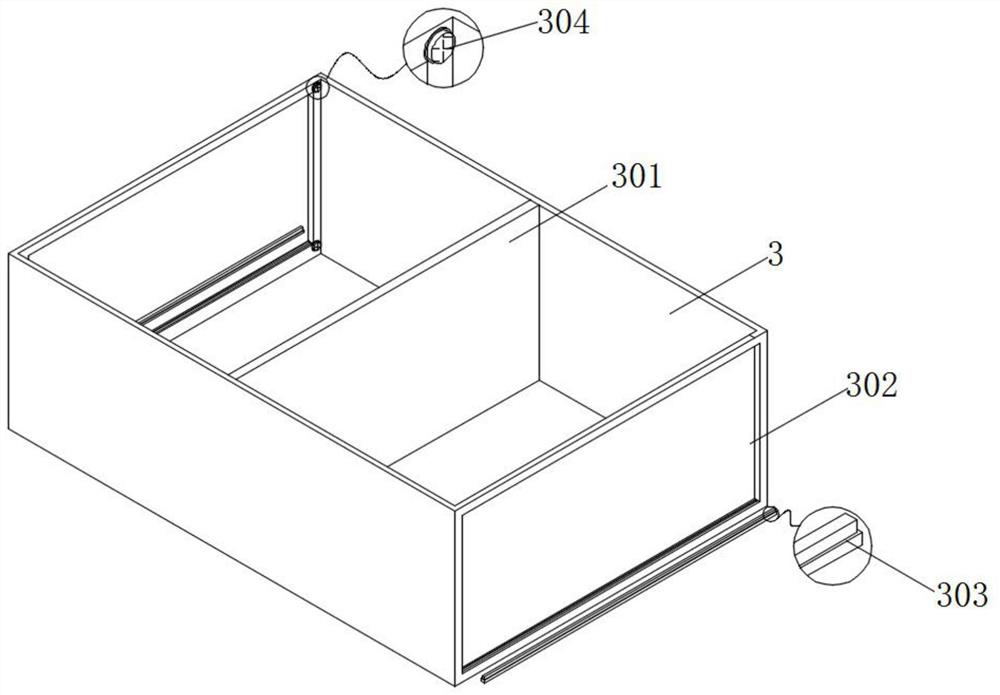

[0046] see figure 1 , an embodiment provided by the present invention: an ultra-high-speed palletizing and handling robot for intelligent logistics, comprising a bottom plate 1, a storage cabinet 3 is installed on the top of the bottom plate 1, and the front and back of the storage cabinet 3 are installed with Symmetrically arranged aggregate structure 4;

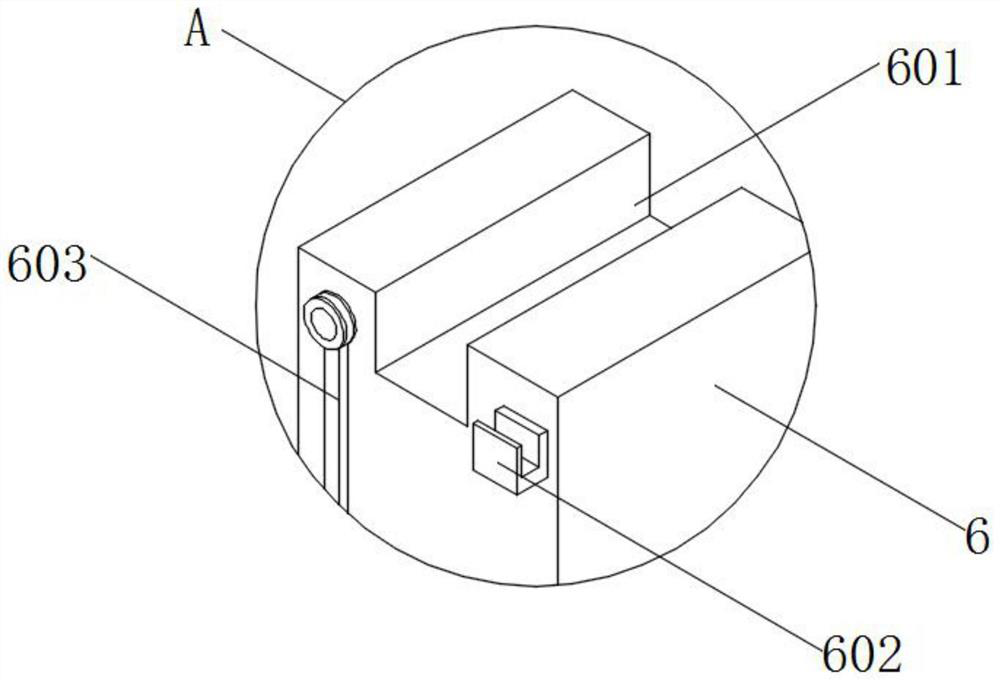

[0047] The collection structure 4 includes an infrared range finder 401, a stepping motor 402, a No. 1 electric telescopic rod 403, a No. 2 electric telescopic rod 404 and a No. 3 electric telescopic rod 405, wherein the infrared range finder 401 is installed on the lifting rod. 6. A side surface away from the storage cabinet 3, the stepping motor 402 is installed on the front and back of the storage cabinet 3, and a No. 1 electric telescopic rod 403 is installed at the output end of the stepping motor 402, and the No. 1 electric telescopic rod The tail end of 403 is connected with a No. 2 electric telescopic rod 404, and ...

Embodiment 2

[0051] see image 3 and Figure 8 , an embodiment provided by the present invention: an ultra-high-speed palletizing and handling robot for intelligent logistics, including an electronic tension meter 9, and lifting rods 6 are installed on the top four corners of the bottom plate 1, and the top of the lifting rod 6 slides An operation panel 2 is installed, a turntable 201 is installed on the top of the operation panel 2, a robot arm 202 is installed on the top of the turntable 201, and an electronic tension gauge 9 is installed at the bottom of the tail end of the robot arm 202. The bottom of the meter 9 is installed with a symmetrically arranged No. 1 baffle 901 through a shaft, the rear end of the No. 1 baffle 901 is installed with a second baffle 902 through the shaft, and the rear end of the second baffle 902 is installed There is a third baffle 903 arranged obliquely, and the third baffle 903 is inclined inward, and the inner wall of a group of the first baffles 901 is i...

Embodiment 3

[0057] see Figure 5 and Image 6 , an embodiment provided by the present invention: an ultra-high-speed palletizing and handling robot for intelligent logistics, including a moving cylinder 7, a mounting block 101 is installed on the front and back of the bottom plate 1, and the bottom thread of the mounting block 101 is A moving cylinder 7 is connected, and a round rod is installed through the inside of the moving cylinder 7, and rollers 703 are respectively sleeved on both ends of the round rod. The surface of the moving cylinder 7 is installed with symmetrically arranged L-shaped struts , a drive motor 701 is installed on the top of a group of struts, the output end of the drive motor 701 is connected with a transmission 702, the output end of the transmission 702 is connected with one end of the round rod, and the other group of the L-shaped struts A counterweight 704 is installed on the top of the .

[0058] Specifically, when the moving cylinder 7 does not need to be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com