Method for transferring and device for handling electronic components

A technology of electronic components and transmission components, applied in the direction of electrical components, electrical components, circuits, etc., can solve problems such as speed reduction and complex mechanical structures, and achieve the effects of improving reliability, increasing processing speed, and simplifying further processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] It should be noted here that the only difference in the reference symbols of the same elements or corresponding elements in the various drawings lies in the first number and / or the letter appended thereto.

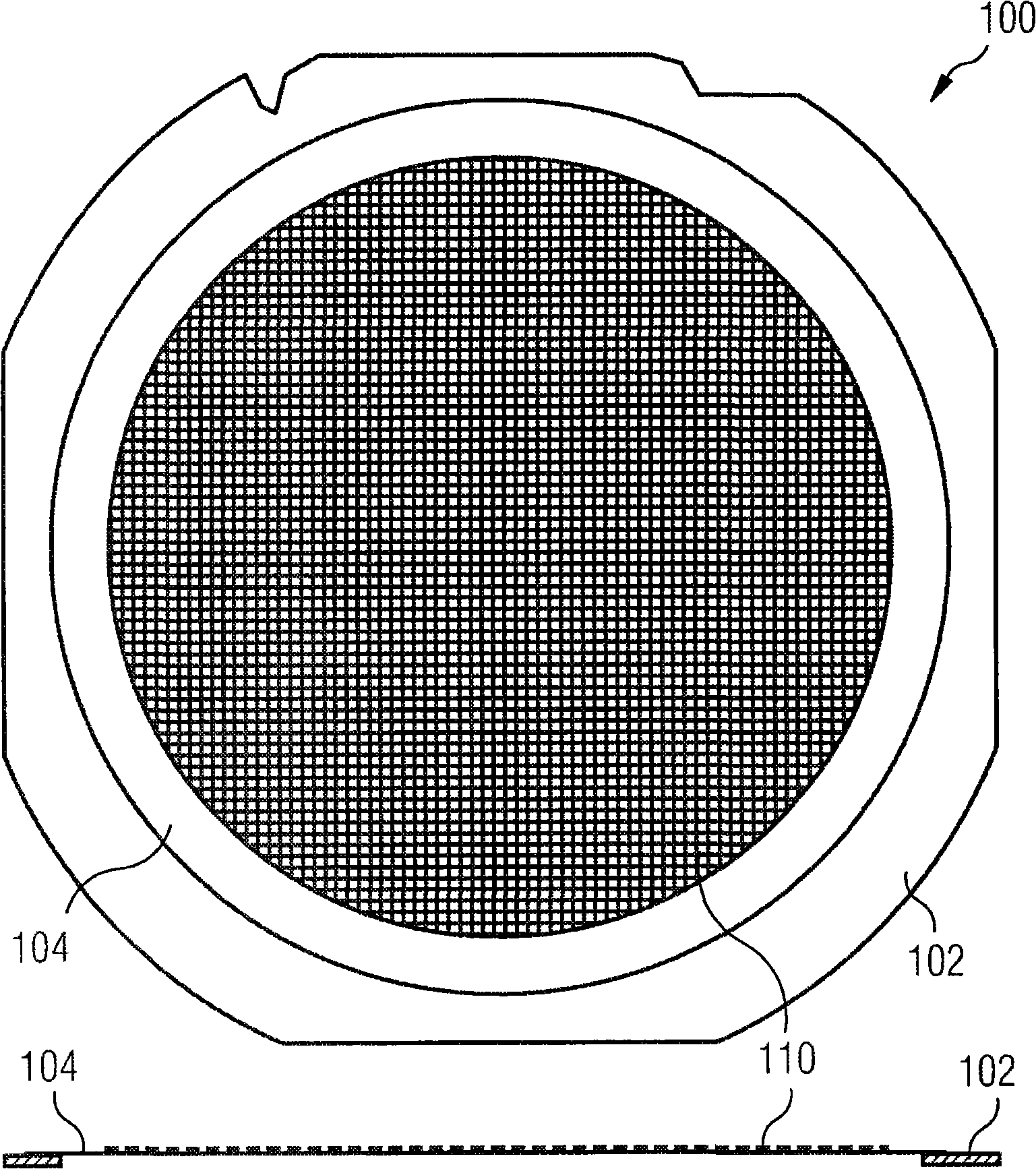

[0036] figure 1 The wafer holding device 100 shown has a ring clamp 102 to which a carrier film 104 is fastened. An entire wafer system consisting of a plurality of electronic components 110 is fixed on the carrier film 104 by means of adhesive forces. Electronic components 110 without housings are arranged on the adhesive carrier film 104 in the form of a mesh. The way to load the component 110 on the wafer holding device 100 is to first glue the entire disk-shaped wafer on the carrier film 104 . The way to divide the wafer into a plurality of electronic components 110 is to saw the wafer along the intersection lines perpendicular to each other with a precision sawing tool, or to divide the wafer through a precise etching process. The connection contacts of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com