Vacuum protecting sleeve

A vacuum protection and air technology, which is applied in the direction of preventing mechanical damage to containers, containers, packaging, etc., can solve the problems of damaging the surface of the sphere, poor positioning of the sphere, and easy damage, and achieves the effect of uniform pumping and improved positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following are specific embodiments of the present invention and the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

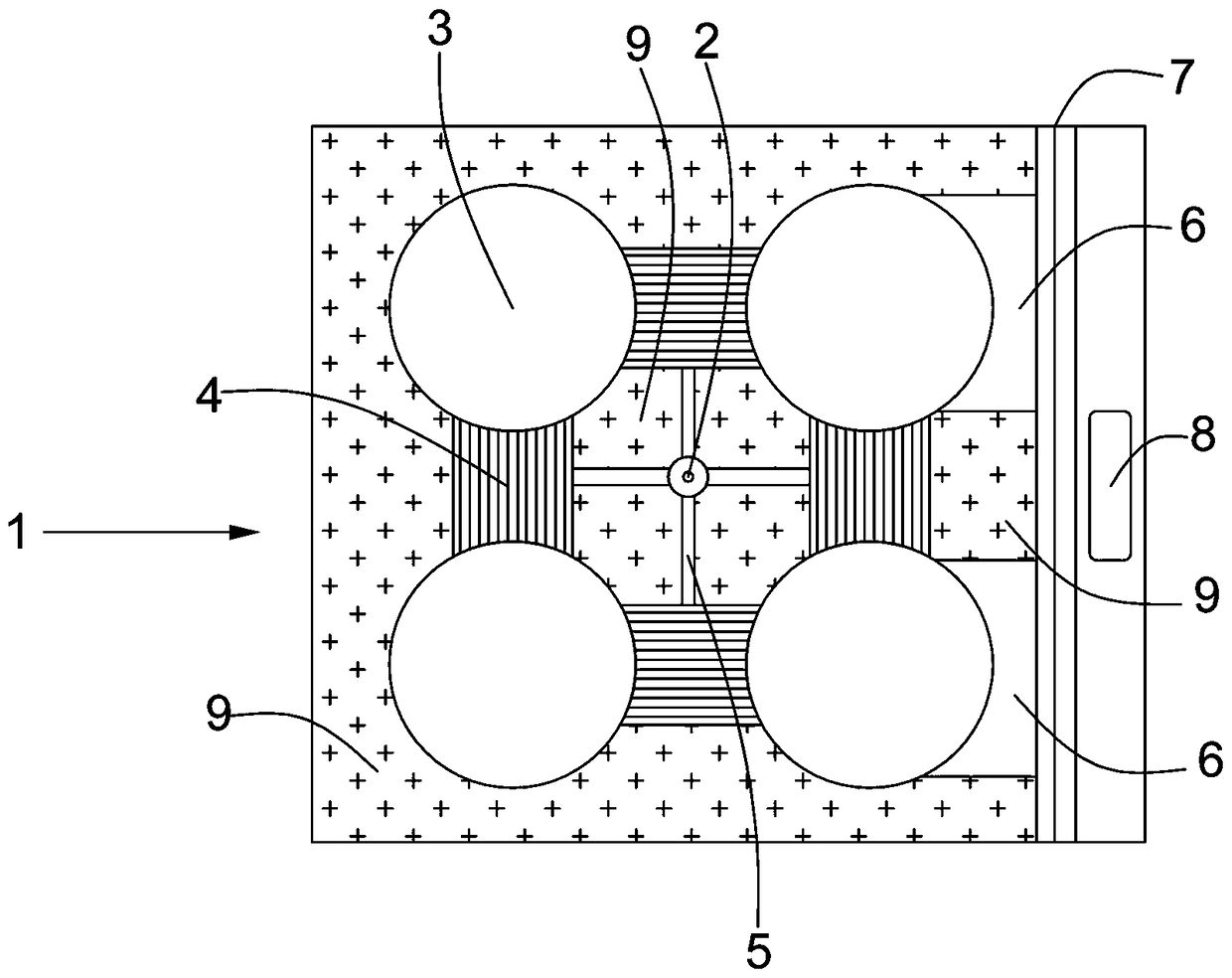

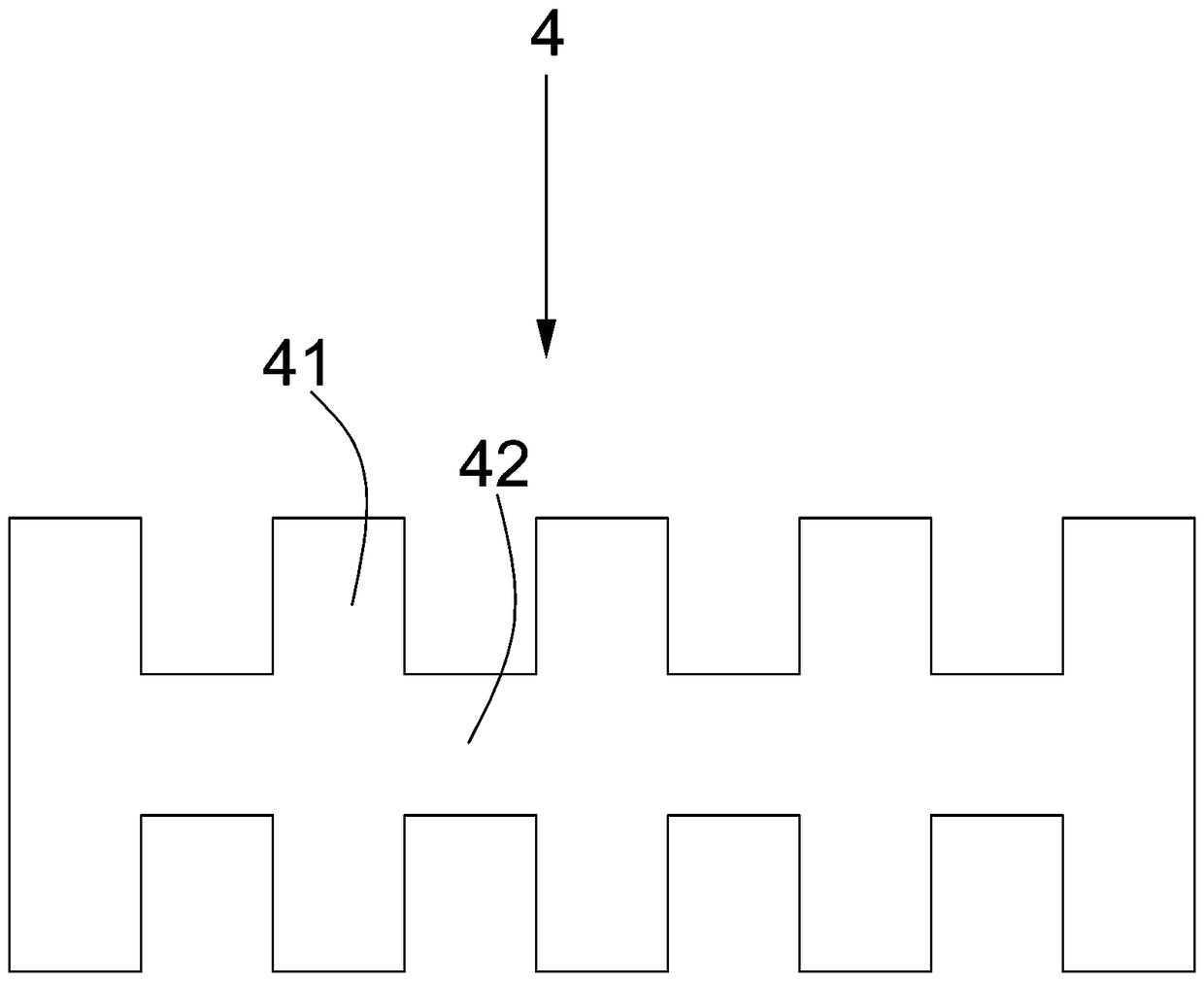

[0019] see figure 1 , The vacuum protective cover of the present invention includes a bag body 1 and an air suction nozzle 2 for sucking out the air in the bag body 1 . The bag body 1 is provided with a plurality of accommodation cavities 3 for accommodating spheres, and each sphere corresponds to one accommodating cavity 3. When the spheres are packaged and pumped, the spheres will not run wild, which improves the positioning of the spheres, and at the same time does not Time is wasted due to the scrambling of the ball and the need to help the ball to the right position, which ensures the smooth progress of the pumping work and improves work efficiency. The accommodating cavities 3 communicate with each other through the elastic connecting cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com