Thrust reverser having aerodynamic coupling for front frame

A technology of thrust reversal and front frame, applied in the direction of jet propulsion devices, machines/engines, etc., can solve problems such as reducing the efficiency of thrust reversal equipment, and achieve the effect of optimized positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

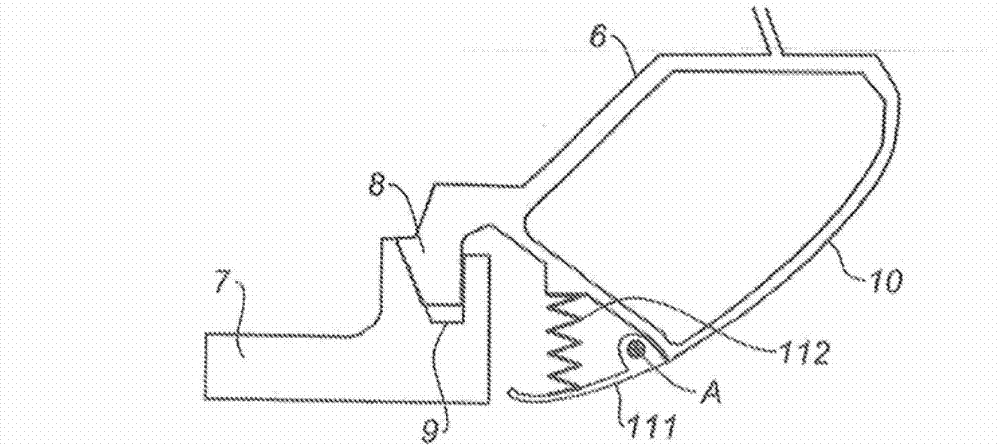

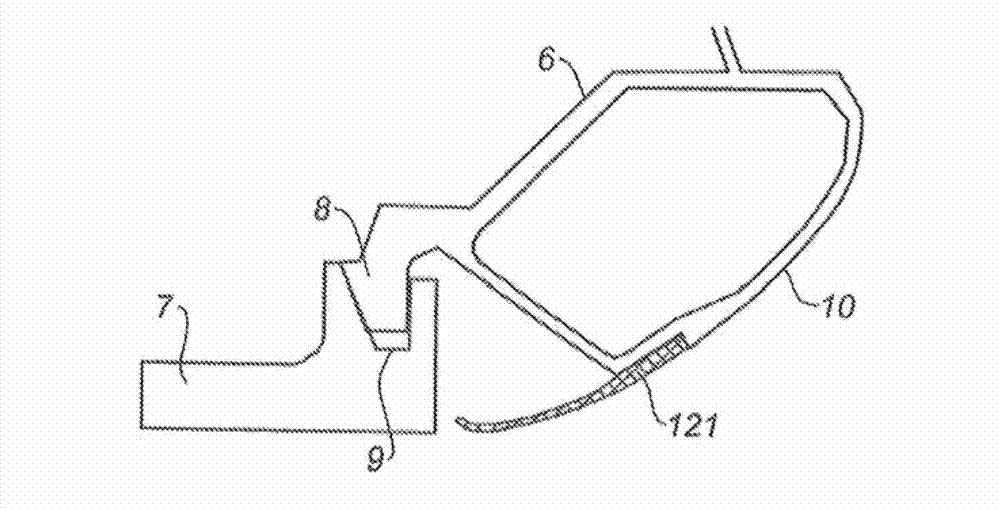

Embodiment Construction

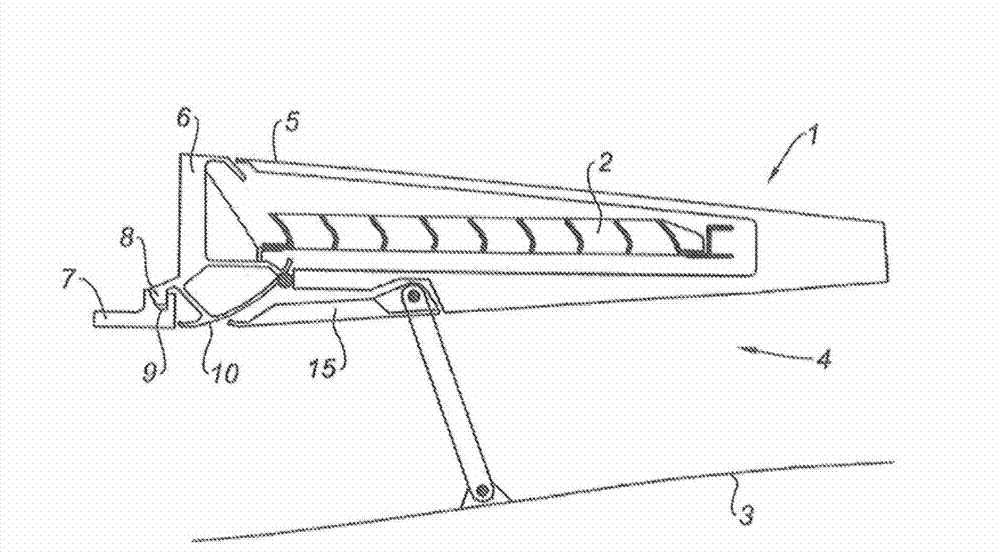

[0049] figure 1 A thrust reversal device 1 with a deflection grid 2 is schematically shown in longitudinal section.

[0050] This thrust reversal device 1 is equipped with a rear section surrounding the nacelle of the turbojet engine (not shown) and together with a fixed internal fixed fairing 3 at the rear of the turbojet engine defines the so-called The flow path 4 through which the second air flow flows.

[0051] Said thrust reversal device 1 comprises a movable cowl 5 mounted so as to be able to move in translation along the substantially longitudinal axis of the nacelle between an open position and a closed position in which said movable cowl 5 has The reverse movement replaces the passage in the nacelle and exposes the deflection grille 2 , said movable cowl 5 ensuring the continuity of the nacelle and covering said deflection grille 2 in the closed position.

[0052] The movable hood 5 is movable relative to a fixed structure comprising on the one hand support and gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com