Reliable and anti-loose one-way isolating valve structure and pressure cylinder structure

An isolation valve, anti-loosening technology, applied in the direction of control valve, valve device, functional valve type, etc., can solve the problem of easy loosening of valve seat and support sleeve.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

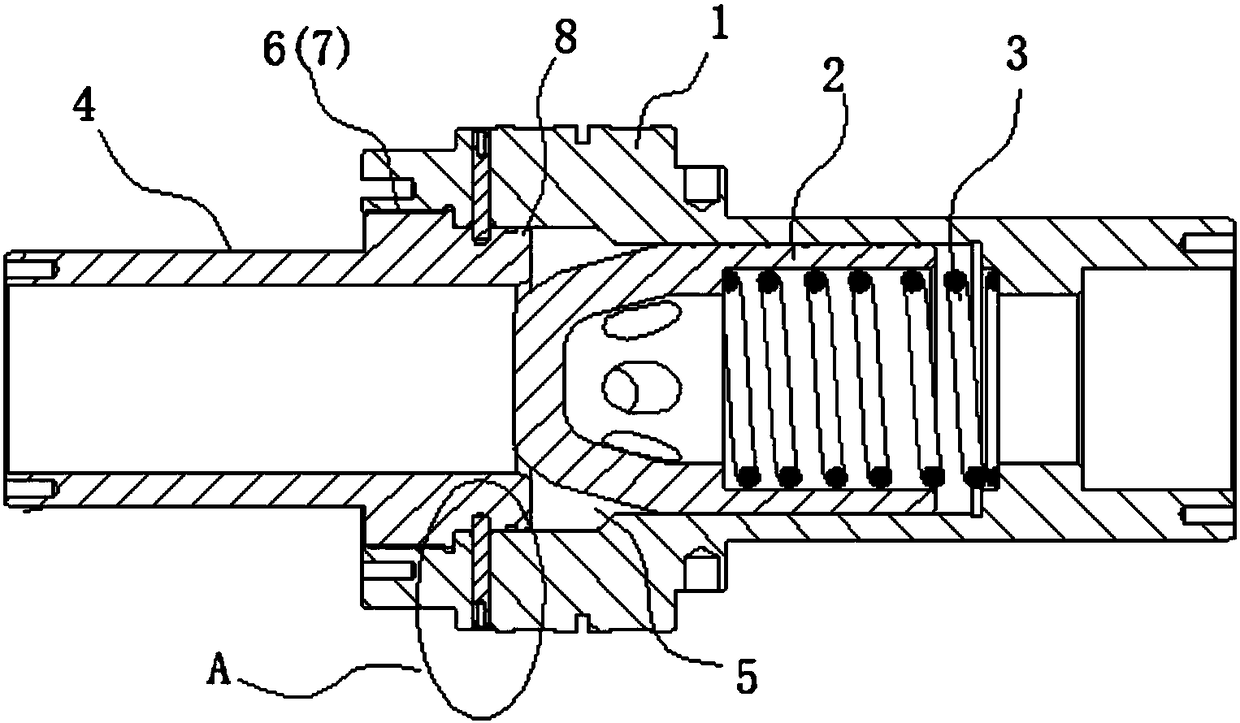

[0028] Refer to attached Figure 1-2 As shown, a reliable and anti-loose one-way isolation valve structure, the one-way isolation valve includes a support sleeve 1 , a valve core 2 , a spring 3 and a valve seat 4 .

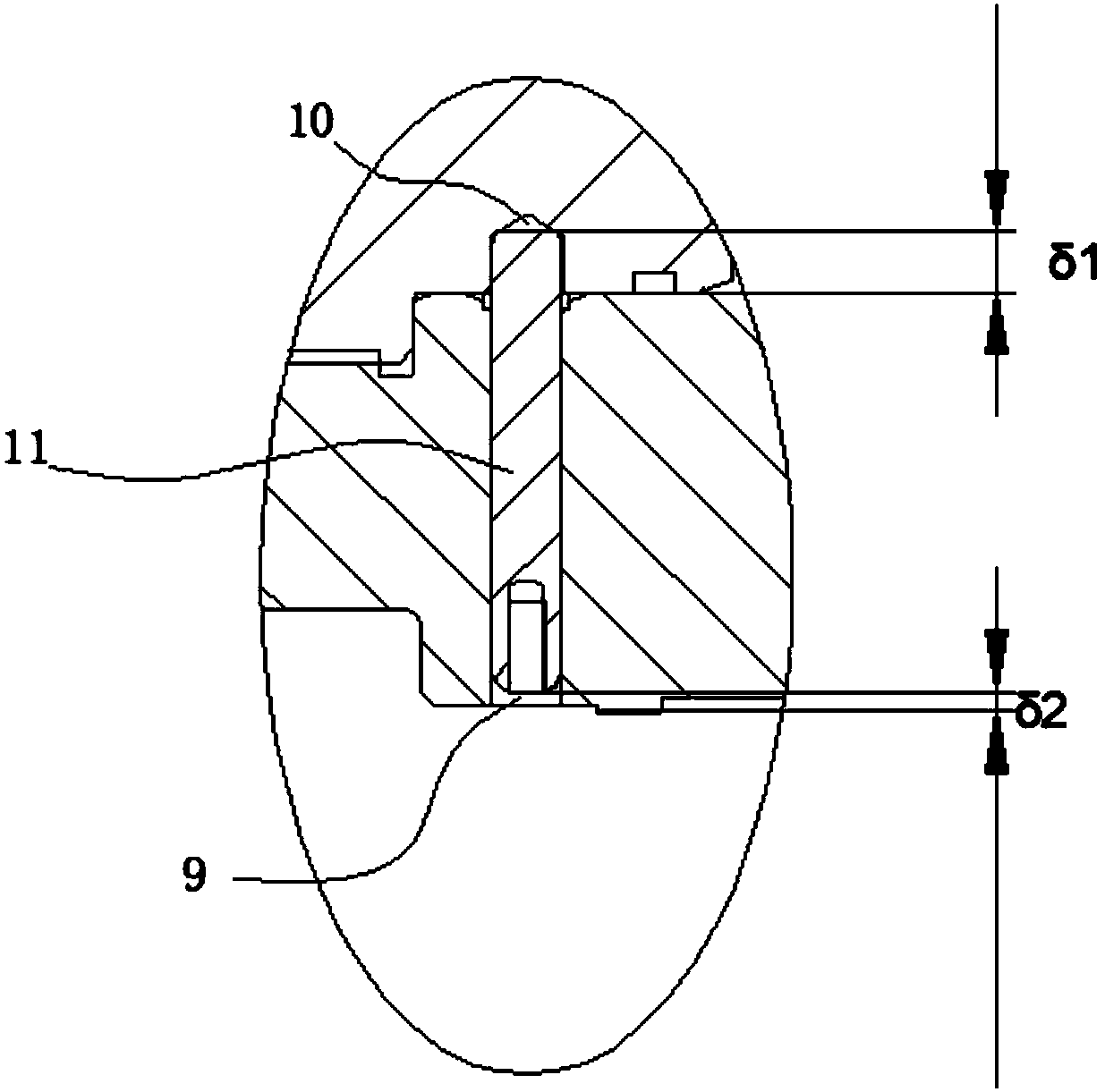

[0029] The support sleeve 1 is provided with a cavity 5 inside, and the cavity 5 is located at the left end of the support sleeve 1 and has an opening. The cross-sectional shape of the opening is stepped. Due to the stepped structure, the diameter of the opening gradually decreases from the outside of the cavity 5 to the inside of the cavity 5 . There is an internal thread 6 at the position with the largest opening diameter, and the shape of the right end of the valve seat 4 matches the shape of the opening. The right end of the valve seat 4 includes a wider part 7 and a narrower part 8, where the wider part 7 and the narrower part 8 For relative description, that is, the width dimension of the wider portion 7 is larger than that of the narrower portion 8 . The ...

Embodiment 2

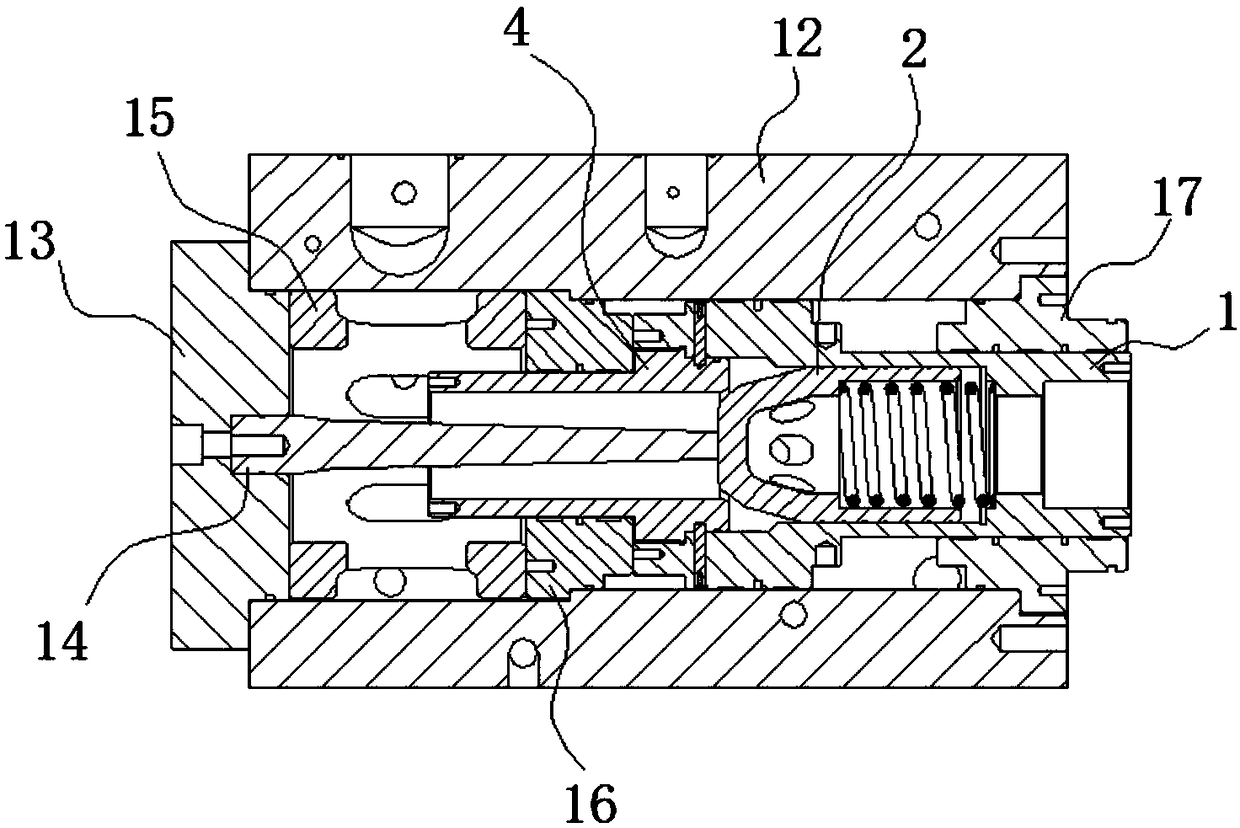

[0035] see image 3 As shown, a booster cylinder structure includes a cylinder body 12, a ram base 13, a ram 14, a support 15, a guide sleeve II 16, a guide sleeve I 17 and the one-way isolation valve structure described in Embodiment 1.

[0036] The cylinder body 12 is hollow and has openings at both ends.

[0037] The ejector rod seat 13 is located near the opening of the left end of the cylinder body 12 , and partly protrudes into the cylinder body 12 , and the protruding part is connected with the left end of the ejector rod 14 . The right end of push rod 14 passes through support 15, and valve seat 4 is connected with valve core 2.

[0038] The guide sleeve II16 is located in the cylinder body 12 and sleeved on the valve seat 4 , and the support 15 is located between the guide sleeve II16 and the ejector rod seat 13 .

[0039] The guide sleeve I17 is located near the opening of the right end of the cylinder body 12 and partly extends into the cylinder body 12 . The gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com