Self-locking check bolt with pressed threads, manufacturing mold and manufacturing method

A technology for anti-loosening bolts and manufacturing molds, applied to bolts, threaded fasteners, screws, etc., can solve problems such as easy deformation, accidents, and bolt torque attenuation, and achieve low cost, simple manufacturing, and long anti-loosening period Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

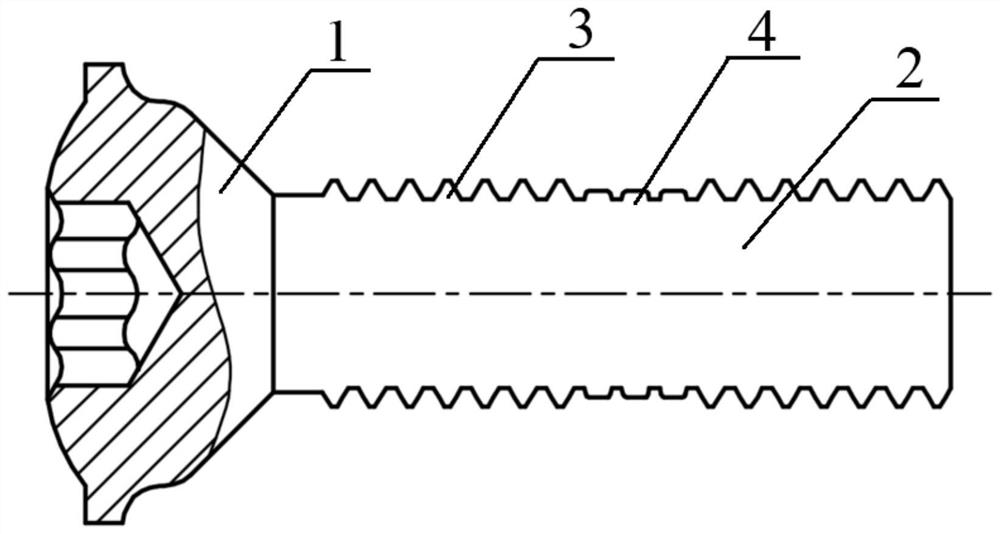

[0041] figure 1 Shown is a self-locking anti-loosening bolt with pressed threads, including a head 1 and a stem 2, the head 1 and the stem 2 are fixedly connected, the stem 2 has a thread 3, the thread 3 includes a pressed thread 4, and the pressed thread The crest of 4 is lower than that of other parts of thread 3, the bottom of pressed thread 4 is flush with the bottom of other parts of thread 3, and the tooth socket of pressed thread 4 is narrower than that of other parts of thread 3. figure 1 The number of turns of the exemplary pressing thread 4 is three, and may be more, so as to increase the effect of self-locking and anti-loosening. Preferably, the profile angle of the pressed thread 4 is 50° to 60°. The crest arc radius of the pressed thread 4 is larger than the crest arc radii of other parts of the thread 3 . The pressed thread 4 is located in the middle of the thread 3, and can be assembled with the thread of the counterpart to interfere with the thread of the cou...

Embodiment 2

[0045] Figure 4 A method of manufacturing a self-locking anti-loosening bolt with pressed threads is shown, comprising the following steps:

[0046] Step S1, blanking: the 10B21 wire material is cut into a cylindrical blank by the inner and outer scissors of the bolt forming machine.

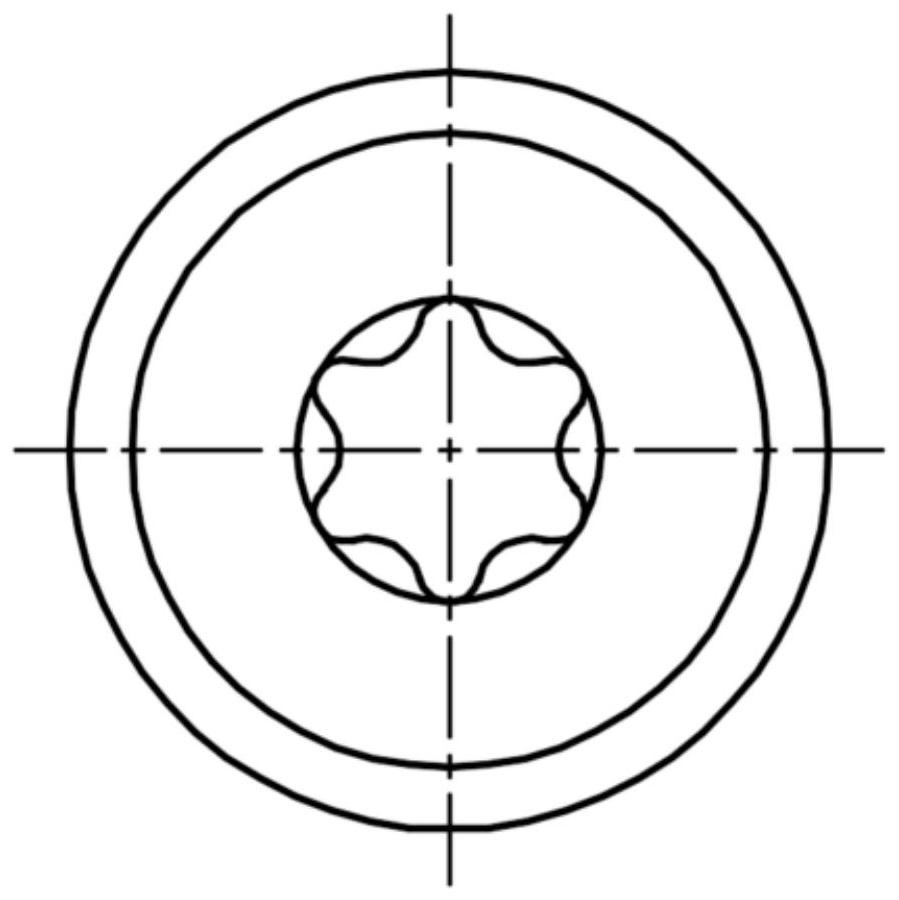

[0047] Step S2, pre-heading: Utilize the pre-heading movable mold (such as Figure 5 shown) for head pre-upsetting. The advantage of using the movable mold is: the billet is all contained in the mold cavity, and it is not easy to produce flash and twist, and the head is pre-upset by punching.

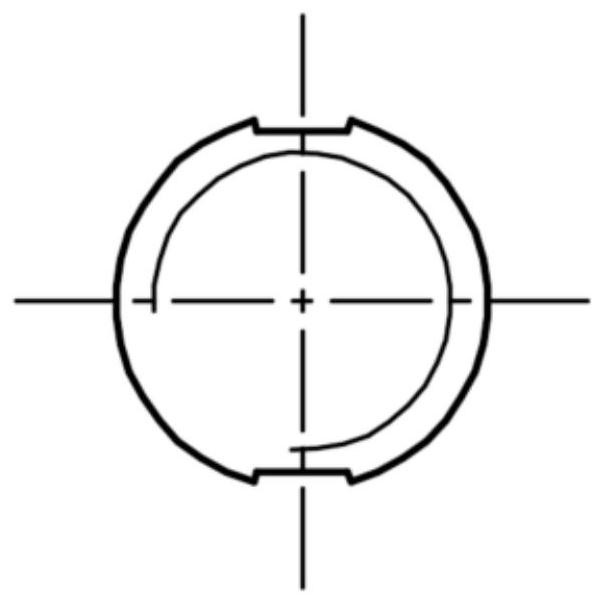

[0048] Step S3, molding: Utilize the molding die (such as Figure 6 Shown) The pre-headed blank is cold-headed.

[0049] Step S4, thread rubbing: threading and thread pressing are carried out on the rod of the bolt through a pair of rubbing plates set opposite to each other and the thread pressing dies arranged on the rubbing plates.

Embodiment 3

[0051] This embodiment provides a mold for manufacturing self-locking and anti-loosening bolts with pressed threads, including a pre-upsetting die, a forming die, a rubbing die and a thread pressing die.

[0052] Figure 5Shown is the pre-heading die arranged in a station of the multi-station cold heading machine, which is composed of a die shell 51, a die cushion block 52, a spring 53, a movable die 54, a punch 55, a die 56, and a die thimble 57. Die spacer 52, spring 53, movable die 54 and punch rod 55 are located in die housing 51, die spacer 52 makes movable die 54 punch downward through spring 53, punch rod 55 is fixedly arranged on die spacer 52, and passes through Through the through hole arranged on the movable die 54, when the movable die 54 finishes stamping, the die pad 52 can drive the punch rod 55 to continue punching. The die thimble 57 penetrates in the die 56 , the blank 58 is placed in the die 56 , and the die thimble 57 withstands the blank 58 . The punch 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com