A Lightweight Infrared Gun Sight

An infrared gun and infrared lens technology, applied in the field of light infrared gun sights, can solve the problems of wrench slippage, low accuracy of repeated clamping, complicated and laborious operation, etc. The effect of the anti-loosening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be described in detail below with reference to the drawings and embodiments.

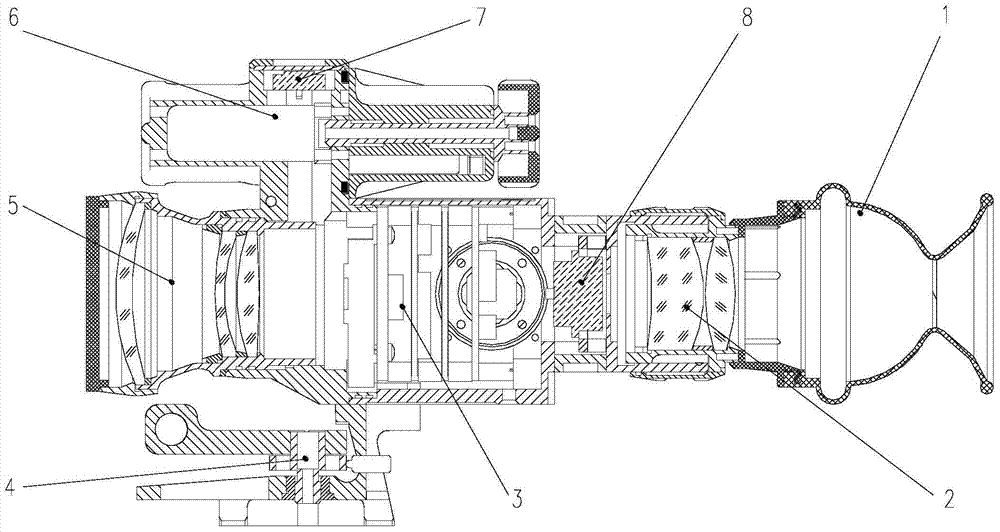

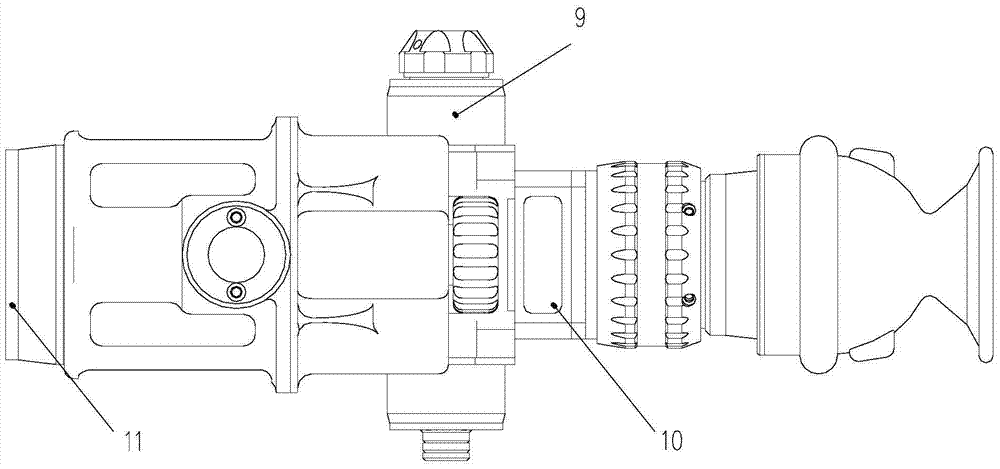

[0063] The invention provides a light infrared gunsight, see attached figure 1 , 2 , Including: light-shielding goggles 1, monocular assembly 2, infrared detector assembly 3, mirror gun connection base assembly 4, athermal infrared lens assembly 5, battery housing assembly 6, mounting base 65, switch / calibration button 7, OLED display 8. Housing assembly 9, transition frame 10 and lens cover 11;

[0064] The light-shielding goggles 1 is a funnel-shaped purchased part, the material is rubber, and the light-blocking sheet is provided at the smallest diameter of the funnel-shaped structure. When the funnel-shaped structure is axially compressed, the light-blocking sheet is automatically opened;

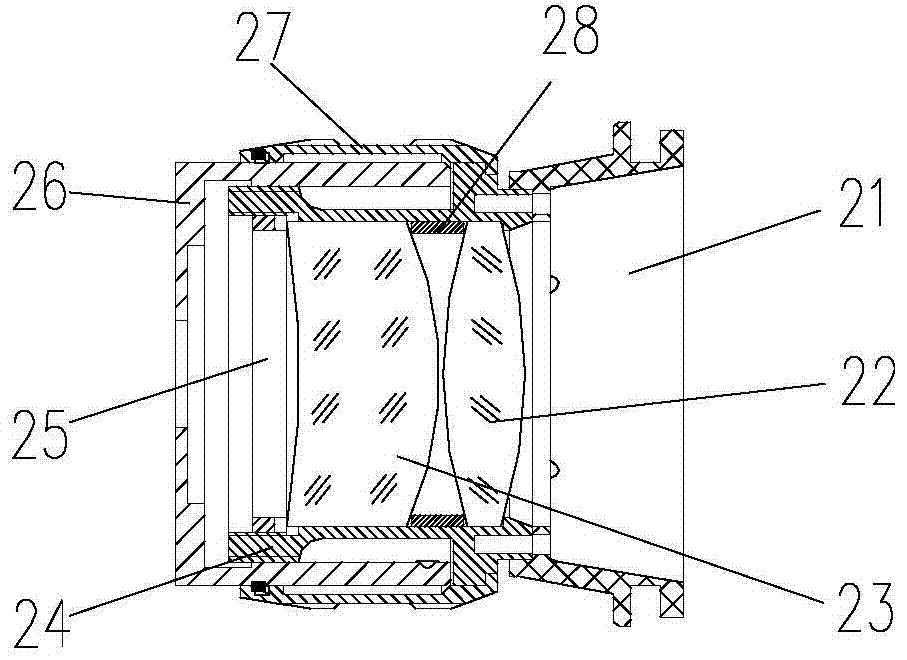

[0065] See attached image 3 , The monocular assembly 2 includes: an eyecup interface 21, a first eyepiece 23, a second eyepiece 22, a monocular inner tube 24, a monocular pressure r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com