Clamping sleeve type straight-through external screw joint

A ferrule type, nut technology, applied in the direction of pipe/pipe joint/pipe fitting, passing element, sealing surface connection, etc., can solve the problems of ferrule loosening and inability to firmly install anti-leakage ferrule, etc., to achieve easy installation , the effect of good gas sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution will be described in detail below through a best embodiment, but the protection scope of the present invention is not limited to the embodiment.

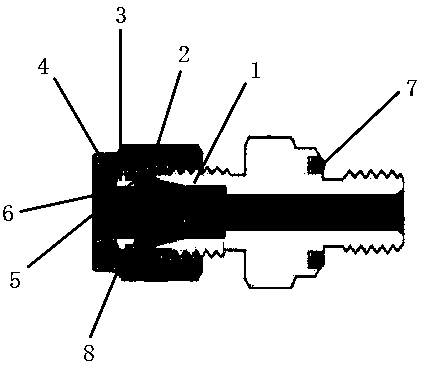

[0017] Such as figure 1 As shown, a ferrule-type straight-through external screw joint includes a joint body 1, a nut 4 and a ferrule 6. The left and right ends of the joint body 1 are respectively provided with threads, and the joint body 1 is connected to the nut through the thread. 4 connection, the middle part of the joint body 1 is provided with an O-shaped groove, and a matching O-shaped sealing ring 7 is respectively installed inside the O-shaped groove, and a front The ferrule 2, the front ferrule 2 is closely fitted with the joint body 1 and the ferrule 6 to form a main seal, the rear end of the front ferrule 2 is provided with a rear ferrule 3, and the rear ferrule 3 and the front ferrule A fixed hinge point 5 is provided at one end connected to the sleeve 2 , and an expansion seal 8 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com