A thermoplastic polyurethane product molding process for special airtight clothing

A thermoplastic polyurethane and molding process technology, applied in the field of thermoplastic polyurethane, can solve the problems of uneven thickness, flow marks, bubbles, etc., and achieve the effect of high appearance and good gas tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The process flow is as follows:

[0023] Step A: Preparation of thermoplastic polyurethane elastomer diaphragm: Add thermoplastic polyurethane pellets (referred to as TPU pellets) to the mixed solution of acetone and tetrahydrofuran with a mass ratio of 1:6, and the mass ratio of TPU pellets to solvent is 1:4, 30 Stir in a water bath until completely dissolved. Pour the solution into a stainless steel shallow dish, place it at room temperature for 5 hours, then put it in an oil bath oven at 70°C for 24 hours, and take out the diaphragm for later use;

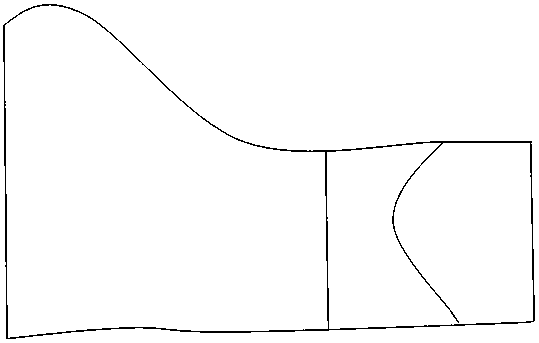

[0024] Step B: Mold preheating: Put the single-opening cylindrical mold (see the attached product diagram) figure 1 ) placed in the middle of the heating plate of the rubber flat vulcanizing machine, pressurized at 3MPa, and turned on the flat vulcanizing machine to heat until the mold temperature stabilized to 155°C;

[0025] Step C: pressurized cooling molding: remove the preheated mold from the flat vulcanizing machi...

Embodiment 2

[0029] The process flow is as follows:

[0030] Step A: Preparation of thermoplastic polyurethane elastomer diaphragm: Add TPU pellets to the mixed solution of acetone and tetrahydrofuran with a mass ratio of 1:7, the mass ratio of TPU pellets to solvent is 1:6, and stir until completely in a water bath at 30°C dissolve. Pour the solution into a stainless steel shallow dish, place it at room temperature for 4 hours, then put it in an oil bath oven at 70°C for 24 hours, and take out the diaphragm for later use;

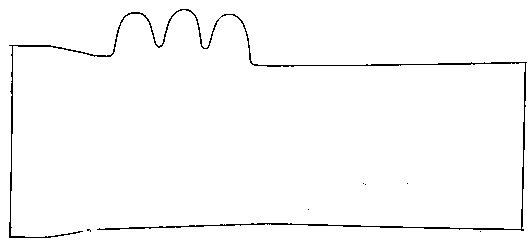

[0031] Step B: Mold preheating: Put the double-opening cylindrical mold (see the attached product diagram) figure 2 ) is placed in the middle of the heating plate of the rubber flat vulcanizing machine, pressurized at 3MPa, and the flat vulcanizing machine is turned on to heat until the mold temperature stabilizes to 160°C;

[0032] Step C: pressurized cooling molding: remove the preheated mold from the flat vulcanizing machine, open the mold, fill the diaphragm int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com