Column body aligning pre-tightening seat with pre-tightening height adjustable function

An adjustable, cylindrical technology, applied in the field of construction, can solve the problems of decreased holding strength, damage to the surface of the main body, and slight structural effects, etc., and achieve the effect of extending the pre-tightening height and increasing the pre-tightening position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

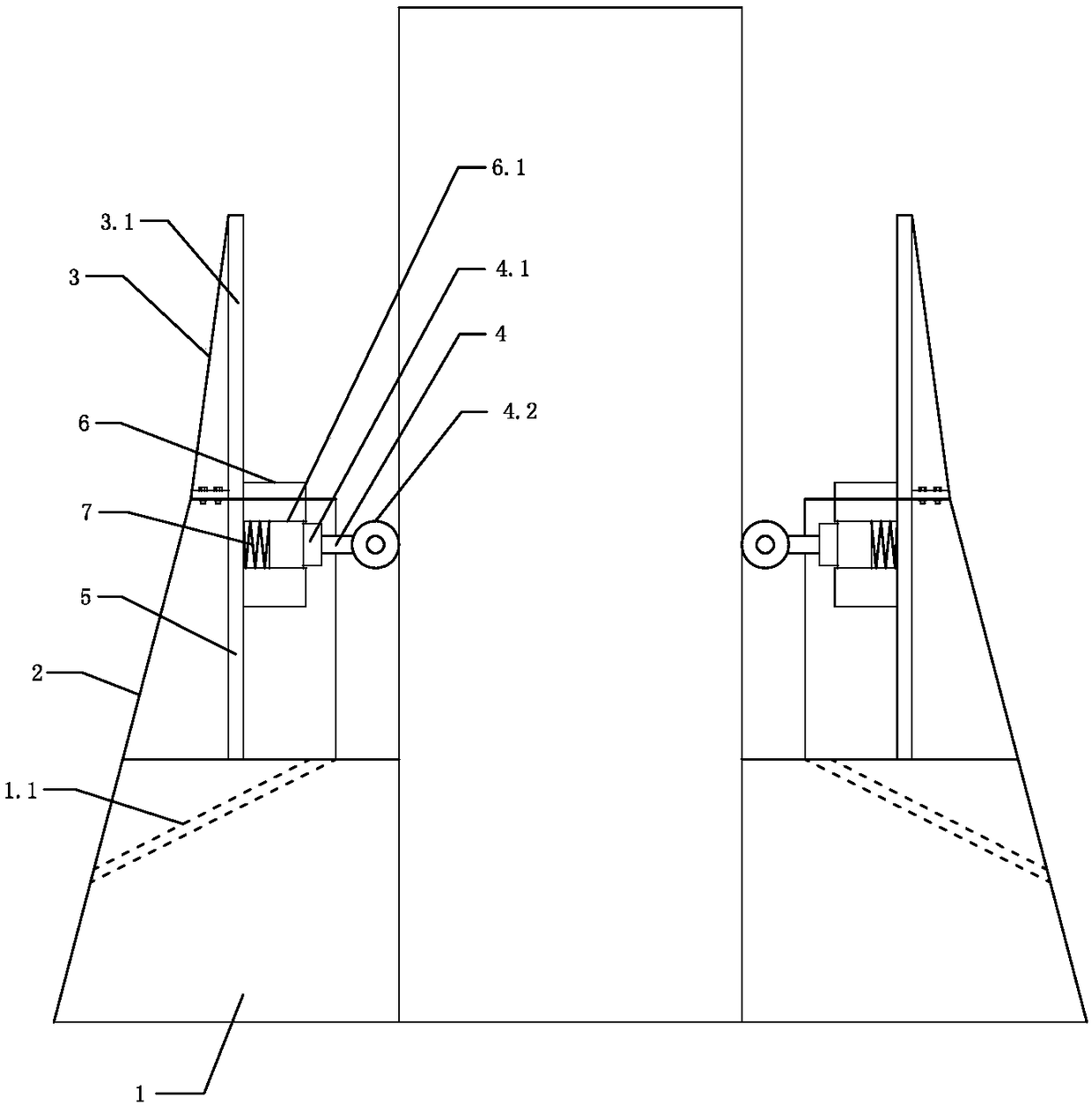

[0023] Such as figure 1 A column collimation and preload seat with adjustable preload height is shown, including:

[0024] Base 1, pre-tightening pile 2, extension section 3 and pre-tightening pressure rod 4;

[0025] The base 1 is arranged outside the bottom end of the cement cylinder, and the base 1 is a truncated cone;

[0026] The number of pre-tensioned piles 2 is 6, all of which are fixed on the upper end surface of the base 1, and the pre-tensioned piles 2 are all parallel to the cement column;

[0027] The installation position of the pre-tightening pile 2 is the end face of the upper ring of the base 1;

[0028] There is a gap between the pre-tensioned pile 2 and the outer wall of the cement cylinder;

[0029] The end face of the inner wall of the pretension pile 2 is provided with a slideway 5, and the slideway is provided with a slider 6 that slides and fits with the slideway 5;

[0030] The slide block 6 is provided with a columnar groove 6.1 with a single-ende...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com