Chili mincing device for producing chili sauce

A technology of chili sauce and lifting device, which is applied in grain processing, food science and other directions, can solve the problems of insufficiently uniform chopping, low work efficiency, and difficult and thorough chopping of chili peppers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

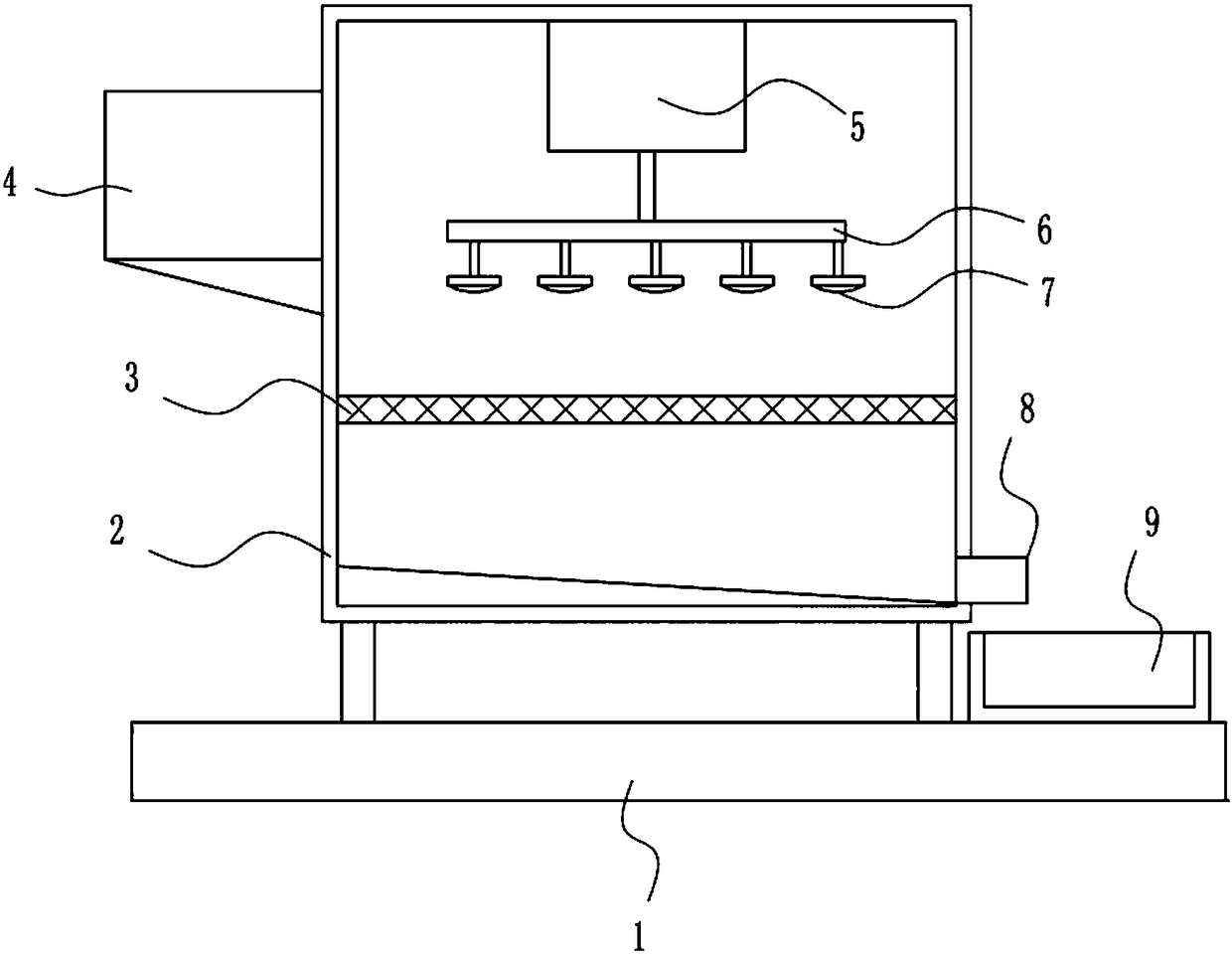

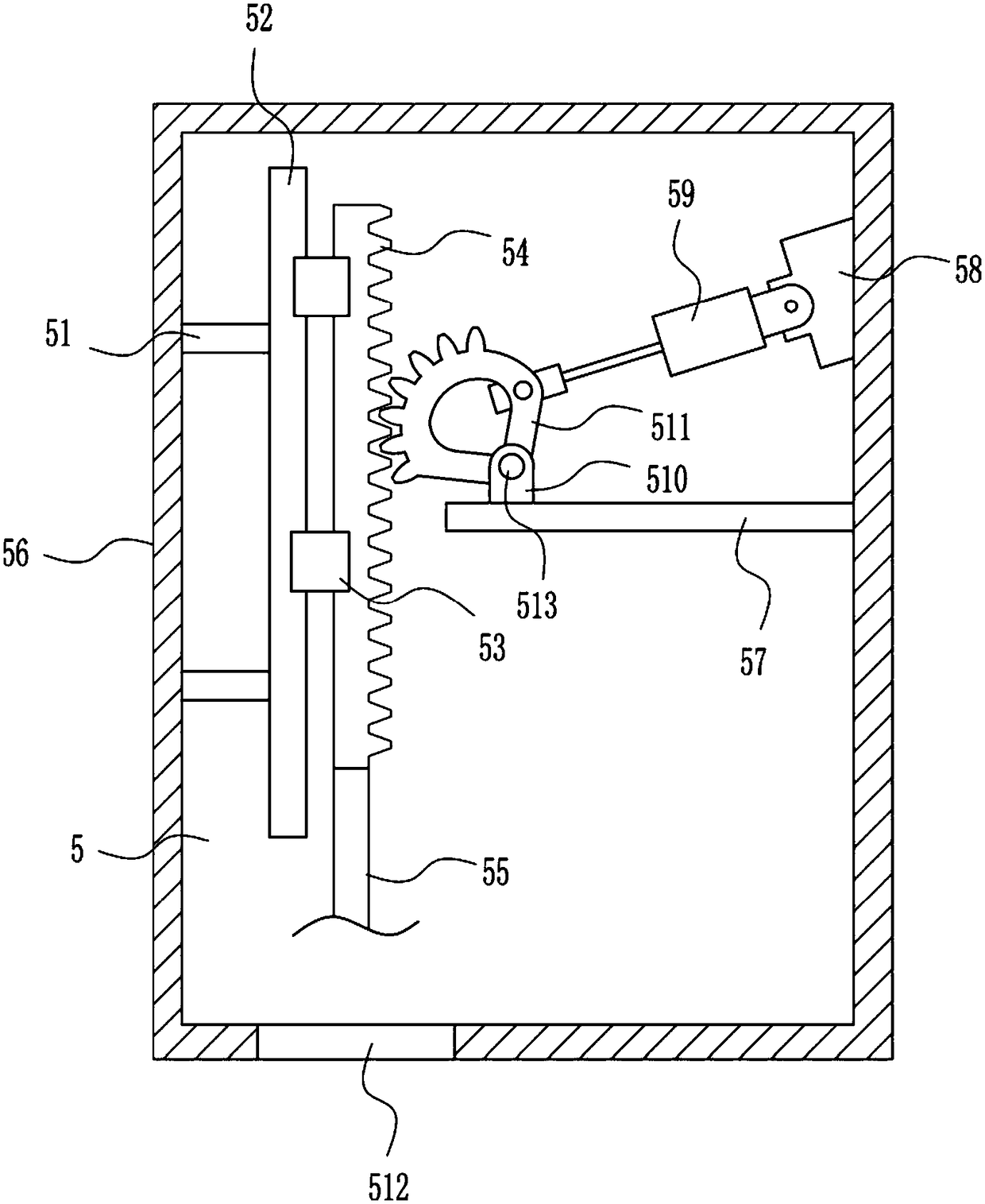

[0034] A crushing pepper device for making chili sauce, such as Figure 1-5 As shown, it includes a base plate 1, a first box body 2, a screen plate 3, a feeding device 4, a lifting device 5, a mounting plate 6, a cutter 7, a discharge pipe 8 and a collection frame 9, and the top of the base plate 1 is welded in the middle The first box body 2, the feeding device 4 is welded on the left side outside the first box body 2, the lifting device 5 is connected to the top of the first box body 2 through bolt connection, and the mounting plate 6 is welded on the bottom of the lifting device 5, and the installation The bottom of the plate 6 is evenly welded with a cutter 7, the left and right walls of the first box 2 are connected with a mesh plate 3 by bolt connection, the outer right bottom of the first box 2 is welded with a discharge pipe 8, and the top of the bottom plate 1 A collecting box 9 is placed on the right side.

Embodiment 2

[0036] A crushing pepper device for making chili sauce, such as Figure 1-5 As shown, it includes a base plate 1, a first box body 2, a screen plate 3, a feeding device 4, a lifting device 5, a mounting plate 6, a cutter 7, a discharge pipe 8 and a collection frame 9, and the top of the base plate 1 is welded in the middle The first box body 2, the feeding device 4 is welded on the left side outside the first box body 2, the lifting device 5 is connected to the top of the first box body 2 through bolt connection, and the mounting plate 6 is welded on the bottom of the lifting device 5, and the installation The bottom of the plate 6 is evenly welded with a cutter 7, the left and right walls of the first box 2 are connected with a mesh plate 3 by bolt connection, the outer right bottom of the first box 2 is welded with a discharge pipe 8, and the top of the bottom plate 1 A collecting box 9 is placed on the right side.

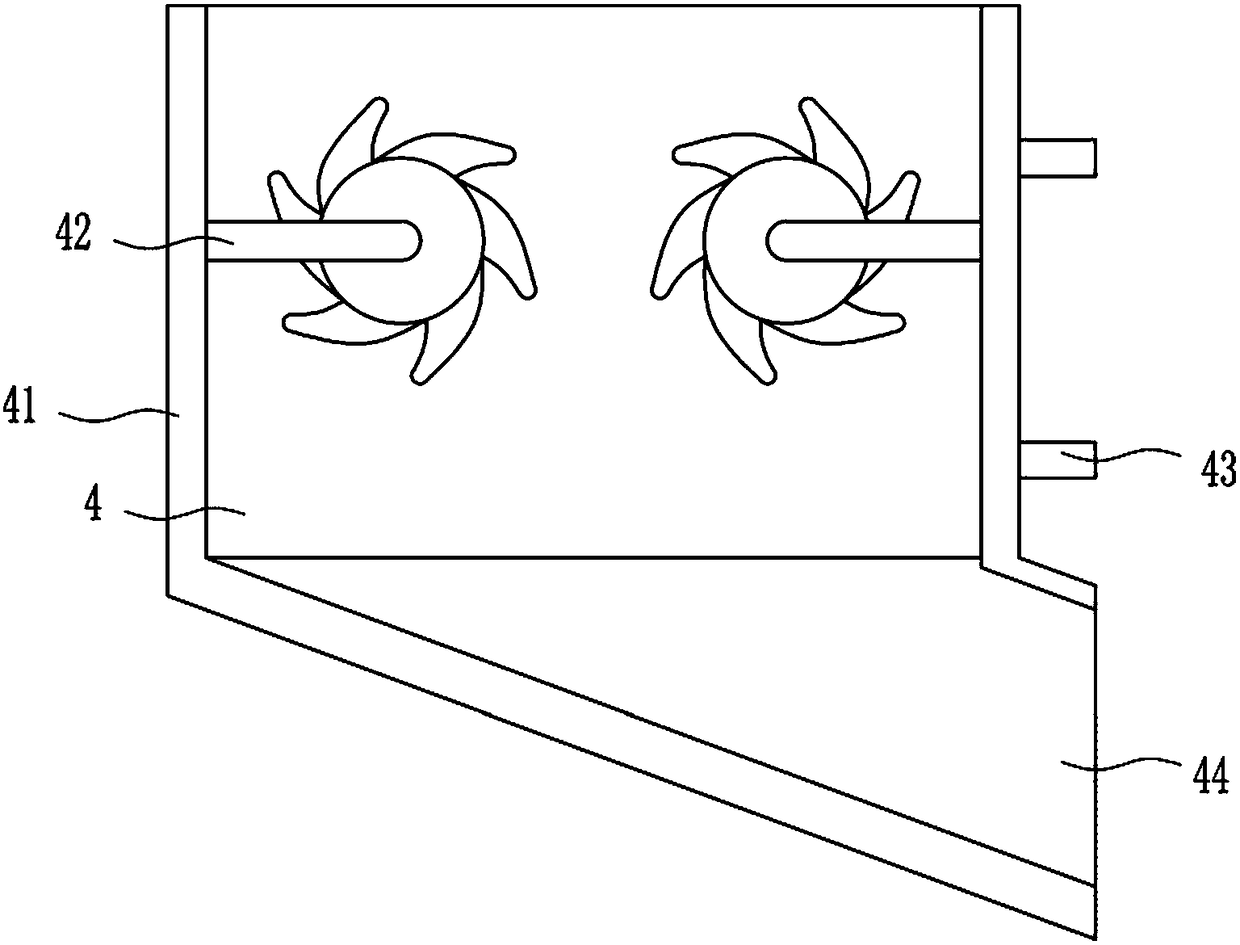

[0037] The feeding device 4 includes a second box body 41...

Embodiment 3

[0039] A crushing pepper device for making chili sauce, such as Figure 1-5 As shown, it includes a base plate 1, a first box body 2, a screen plate 3, a feeding device 4, a lifting device 5, a mounting plate 6, a cutter 7, a discharge pipe 8 and a collection frame 9, and the top of the base plate 1 is welded in the middle The first box body 2, the feeding device 4 is welded on the left side outside the first box body 2, the lifting device 5 is connected to the top of the first box body 2 through bolt connection, and the mounting plate 6 is welded on the bottom of the lifting device 5, and the installation The bottom of the plate 6 is evenly welded with a cutter 7, the left and right walls of the first box 2 are connected with a mesh plate 3 by bolt connection, the outer right bottom of the first box 2 is welded with a discharge pipe 8, and the top of the bottom plate 1 A collecting box 9 is placed on the right side.

[0040] The feeding device 4 includes a second box body 41...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com