Smokeless boiler

A boiler and soot technology is applied in the field of smokeless boilers to achieve the effect of solving the problem of environmental pollution and solving the waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

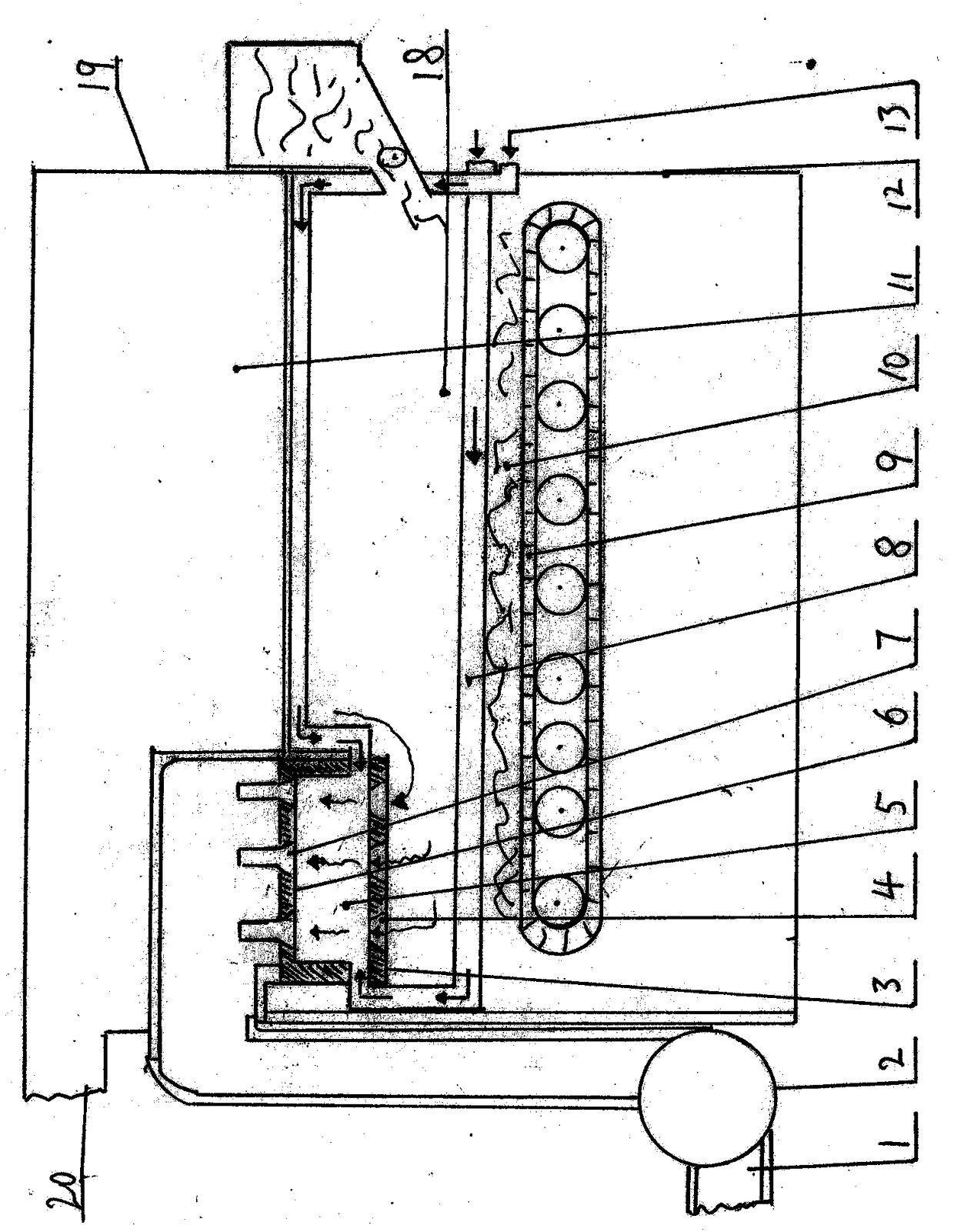

[0055] A smokeless boiler, comprising: a thermal cycle furnace body 19, a combustion furnace 18, and a high-temperature combustion chamber 5; the thermal cycle furnace body 19 is provided with an outer shell and an inner shell 11, and the outer shell is provided with a return pipe (not shown) and an outlet Water pipe 20, inner shell 11, fire grate 9, fuel 10, smoke exhaust pipe 1, smoke exhaust fan 2,

[0056] It is characterized in that: the smokeless boiler is creatively changed from a traditional smoke outlet to a semi-closed high-temperature combustion chamber 5 at the smoke outlet of the furnace;

[0057] The high-temperature combustion-supporting chamber 5 of the smokeless boiler is provided with a lower end cover 3 and an upper end cover 6;

[0058] The lower end cover 3 of the high-temperature combustion-supporting chamber 5 of the smokeless boiler is provided with a furnace hole 4,

[0059] The upper end cover 6 of the high-temperature combustion-supporting chamber 5 o...

Embodiment approach 2

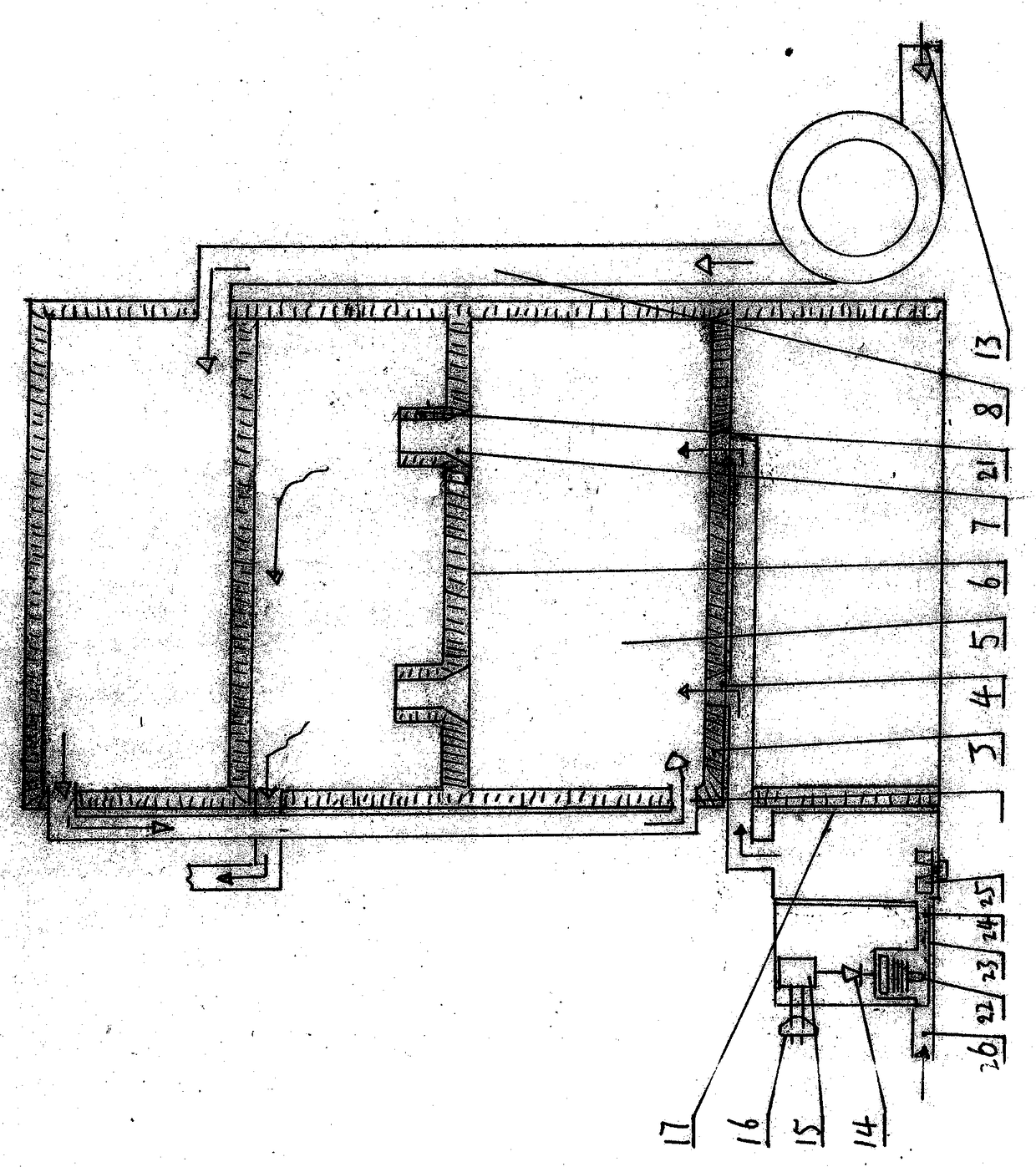

[0069] A smokeless boiler includes: a thermal cycle furnace body 19, a combustion furnace 18, and a high-temperature combustion chamber 5; the thermal cycle furnace body 19 is provided with an outer shell and an inner shell 11, and the outer shell is provided with a return pipe (not shown) and an outlet pipe 20, inner shell 11, fire grate 9, fuel 10, exhaust pipe 1, exhaust fan 2,

[0070] It is characterized in that: the furnace gas combustion device of the energy-saving furnace is creatively changed from the traditional furnace mouth to a semi-closed high-temperature combustion-supporting chamber 5 at the smoke upward exit of the furnace; the high-temperature combustion-supporting chamber 5 of the smokeless boiler is set as Porous grid-shaped; the grid-shaped high-temperature combustion-supporting chamber 5 of the smokeless boiler is provided with an air passage 8 communicating with the outside of the combustion furnace 18, and the air passage 8 can be heated by the combustio...

Embodiment approach 3

[0078] A smokeless boiler, comprising: a combustion furnace 18, a high-temperature combustion chamber 5,

[0079] It is characterized in that: the soot after fuel combustion in the furnace of the smokeless boiler is discharged through the smoke exhaust port of the furnace and enters the high-temperature combustion chamber 5;

[0080] The bottom of the high-temperature combustion-supporting chamber 5 of the smokeless boiler is provided with a soot passage communicating with the upper part and passing through the upper part of the high-temperature combustion-supporting chamber 5, and the high-temperature soot after combustion in the combustion furnace 18 can enter the high-temperature combustion-supporting chamber 5 through the soot passage; A smoke pipe is arranged on the smoke channel of the high temperature combustion chamber 5 of the smokeless boiler;

[0081] The high-temperature combustion-supporting chamber 5 of the smokeless boiler is provided with an air channel 8 commu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap