Pulping method for a food processor

A cooking machine and pulping technology, which is applied to beverage preparation devices, household appliances, applications, etc., can solve the problem of high working noise and achieve the effect of reducing working noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] Figure 7 A process flow diagram corresponding to this example is shown. In this embodiment, the pulping process generally includes the following steps: S100 adding water step: adding water to the barrel of the cooking machine; S201 heating step: heating the pulping material containing raw materials and water; The pulping material with water is pulverized and / or mixed, and the steps of adding water, heating and whipping are repeated n times until the pulping process is completed, wherein, n≥2.

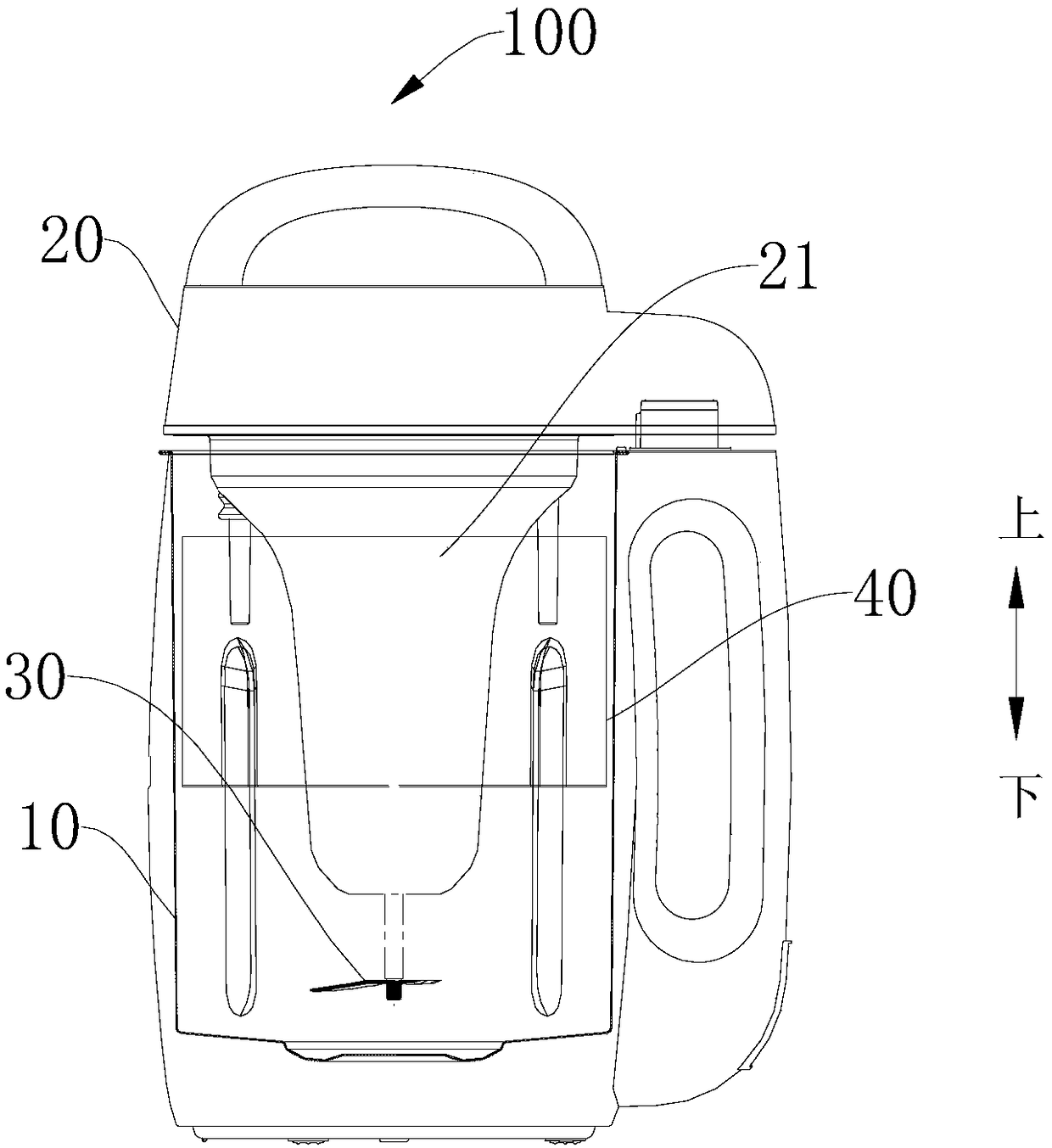

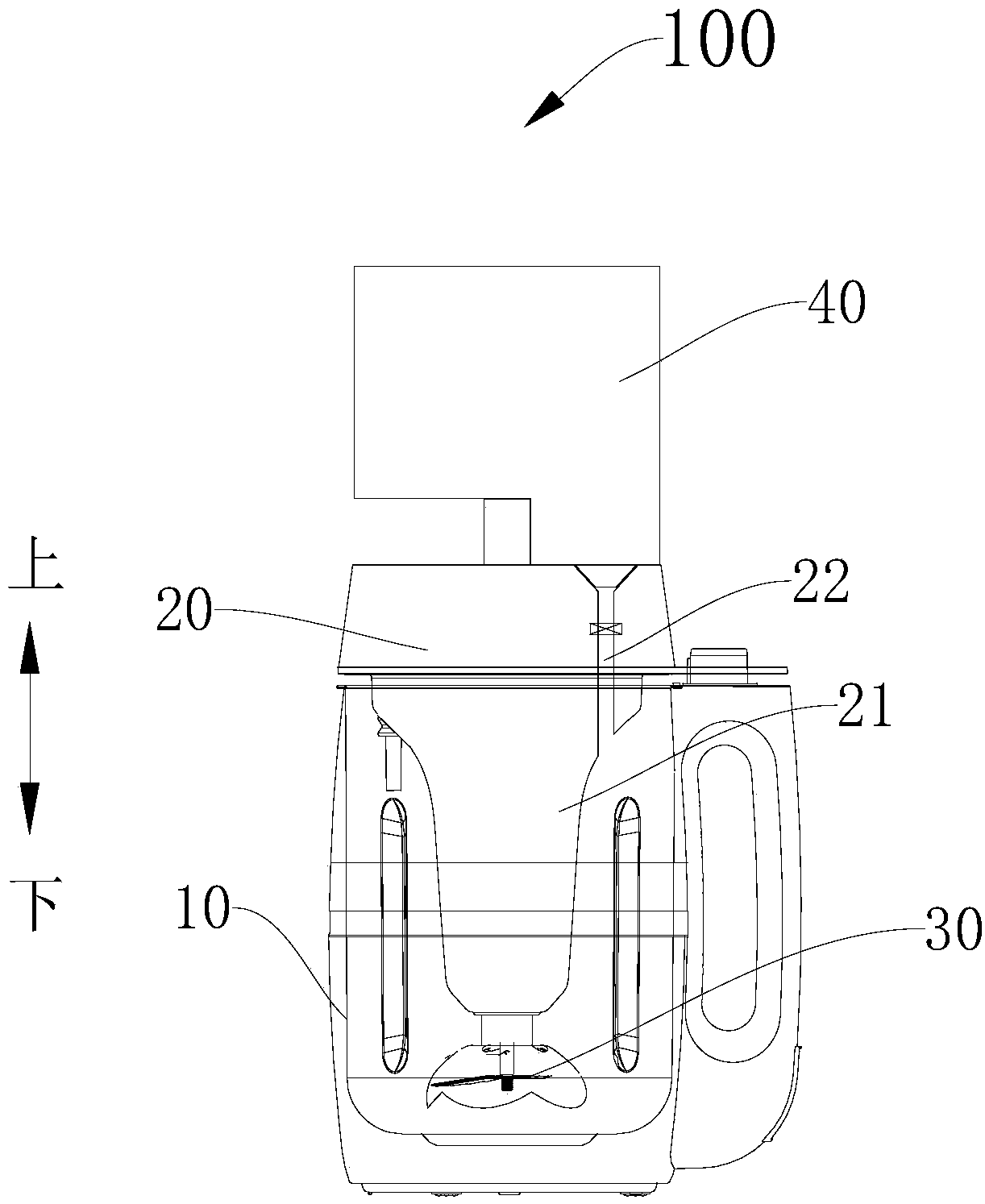

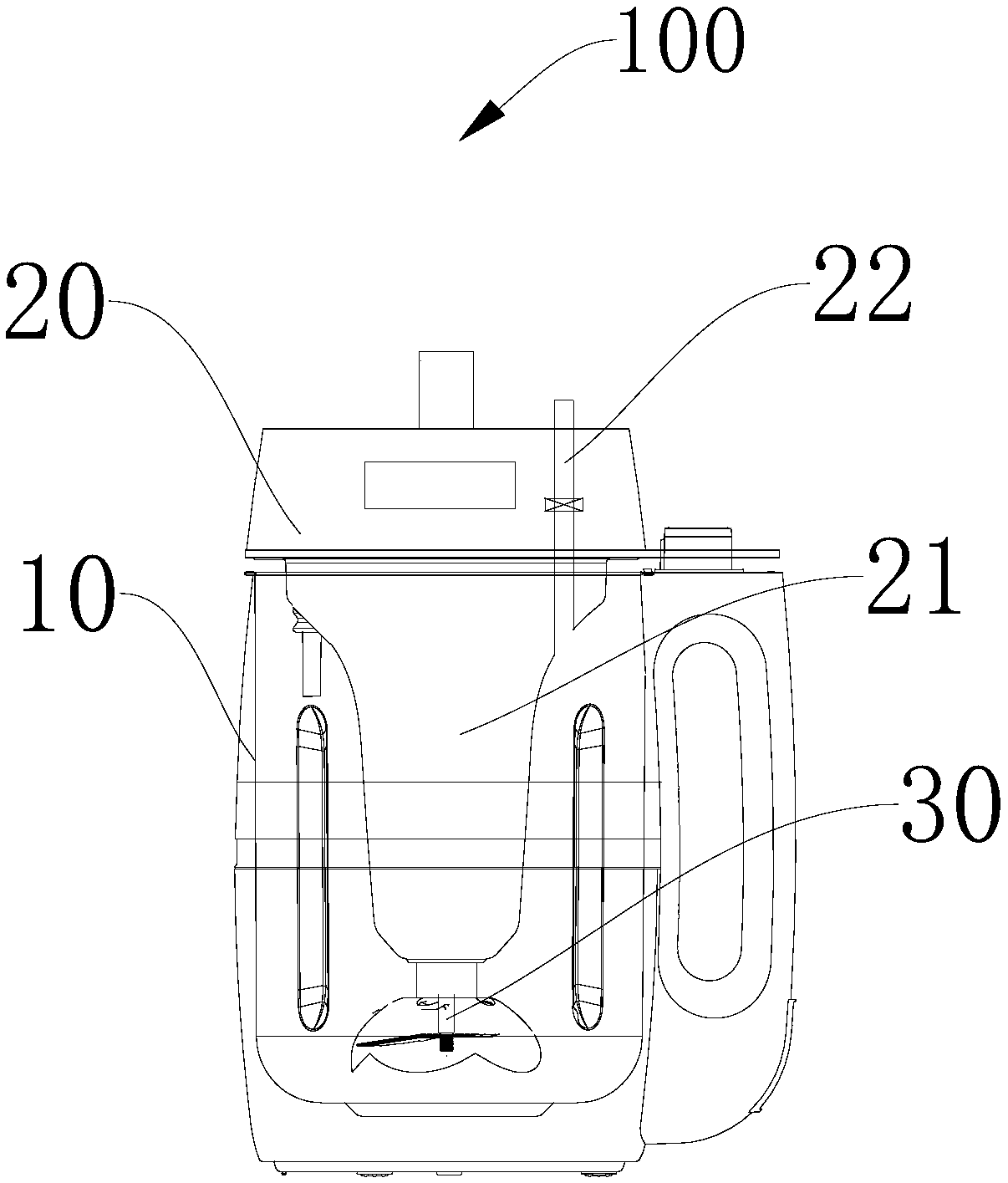

[0091] Specifically, first, water can be added to the barrel body 10 through the water tank 40 of the cooking machine 100, then the pulping material can be heated through the beater 30 of the cooking machine 100, and then the pulping material can be heated by the heater of the cooking machine 100. Whisk and repeat the above steps. It can be understood that the heating can soften the beans, which is beneficial to the crushing of the beans, thereby improving the crushing efficie...

Embodiment 2

[0100] Figure 8 A process flow diagram corresponding to this example is shown. In this embodiment, the pulping process generally includes the following steps: S100 adding water step: adding water to the barrel 10 of the cooking machine 100; S203 whipping step: crushing and / or mixing the pulping material containing raw materials and water; S204 heating step: heating the pulping material containing raw materials and water, repeating the above steps n times until the pulping process is completed, wherein n≥2.

[0101] First, water can be added to the barrel body 10 through the water tank 40 of the cooking machine 100, then the pulping material is heated by the beater 30 of the cooking machine 100, and then the pulping material is whipped by the heater of the cooking machine 100, repeating Follow the steps above. The heating can soften the beans, which is beneficial to the crushing of the beans, thereby improving the crushing efficiency of the cooking machine 100 .

[0102] Fu...

Embodiment 3

[0110] Figure 9 A process flow diagram corresponding to this example is shown. In this embodiment, the pulping process generally includes the following steps: S100 water adding step: adding water to the barrel 10 of the cooking machine 100; S205 whipping step and heating step: simultaneously whipping the pulping material containing raw materials and water and heating, repeating the above steps n times until the pulping process is completed, wherein, n≥2.

[0111] Specifically, first, water can be added to the barrel body 10 through the water tank 40 of the cooking machine 100, then the pulping material is whipped through the beater 30 of the cooking machine 100, and the pulping material is whipped through the heater of the cooking machine 100 at the same time. heating. The heating can soften the beans, which is beneficial to the crushing of the beans, thereby improving the crushing efficiency of the cooking machine 100 . And crushing at the same time during the heating pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com