A machine tool guide rail unloader

A technology of unloader and guide rail, which is applied in the direction of metal processing machinery parts, metal processing equipment, maintenance and safety accessories, etc., and can solve the problems of general practicability and unadjustable spring force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

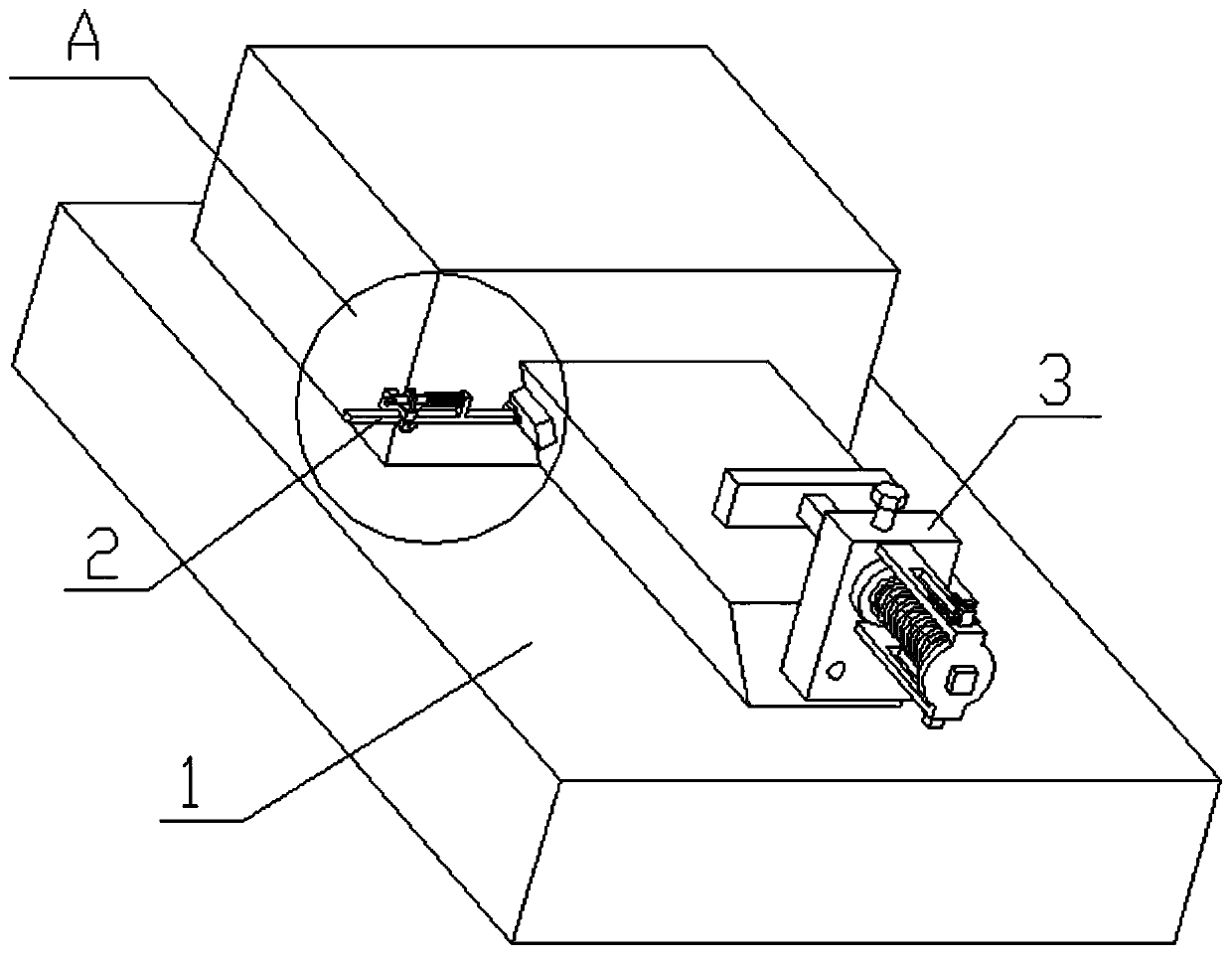

[0031] Combine below Figure 1-13 Describe this embodiment, the present invention relates to the field of mechanical equipment, more specifically a machine tool guide rail unloader, including a carrier plate assembly 1, an unloading assembly I2 and an unloading assembly II3, an unloading assembly I and an unloading assembly II The elastic force of the spring in it can be adjusted to achieve unloading of different strengths.

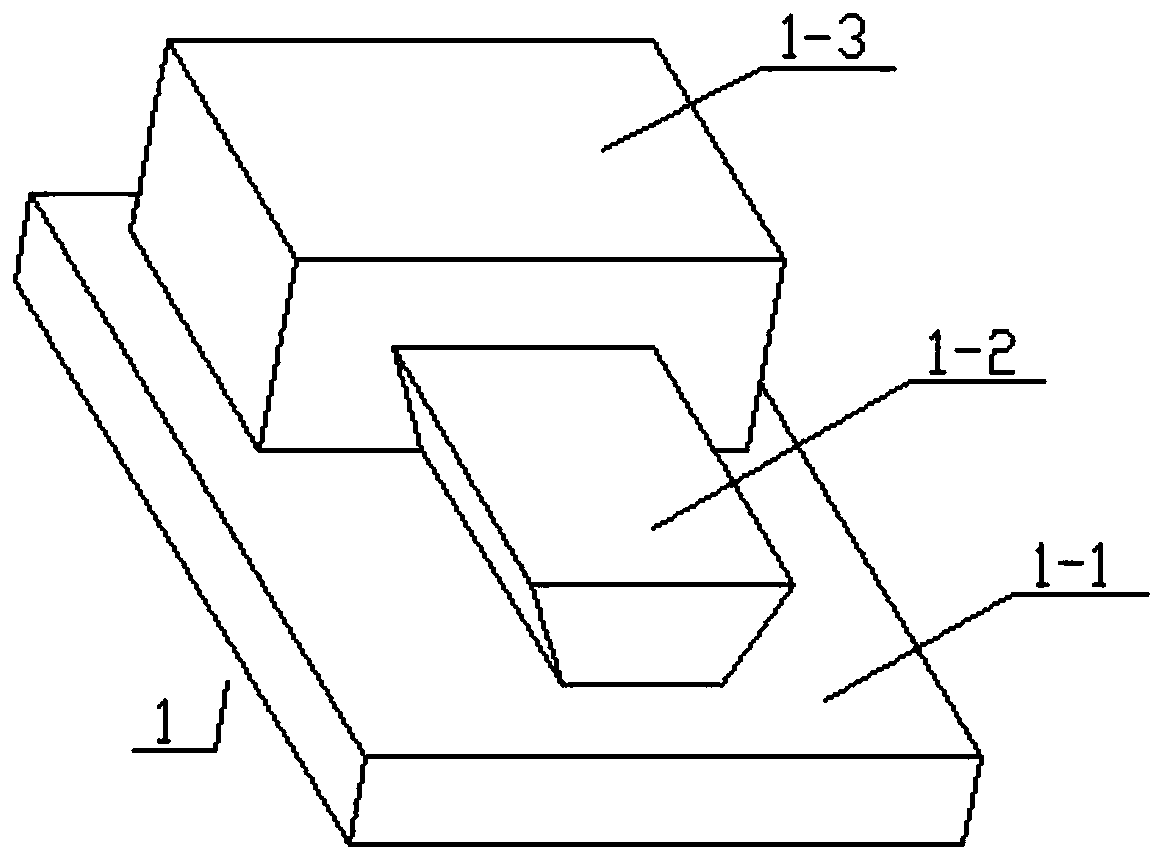

[0032] The carrier board assembly 1 includes a carrier board 1-1, a ladder-shaped slide rail 1-2 and a slider 1-3, the upper end of the carrier board 1-1 is provided with a ladder-shaped slide rail 1-2, and on the ladder-shaped slide rail 1-2 There are sliding parts 1-3 in the sliding connection; the unloading assembly II3 is arranged on the front end of the trapezoidal slide rail 1-2;

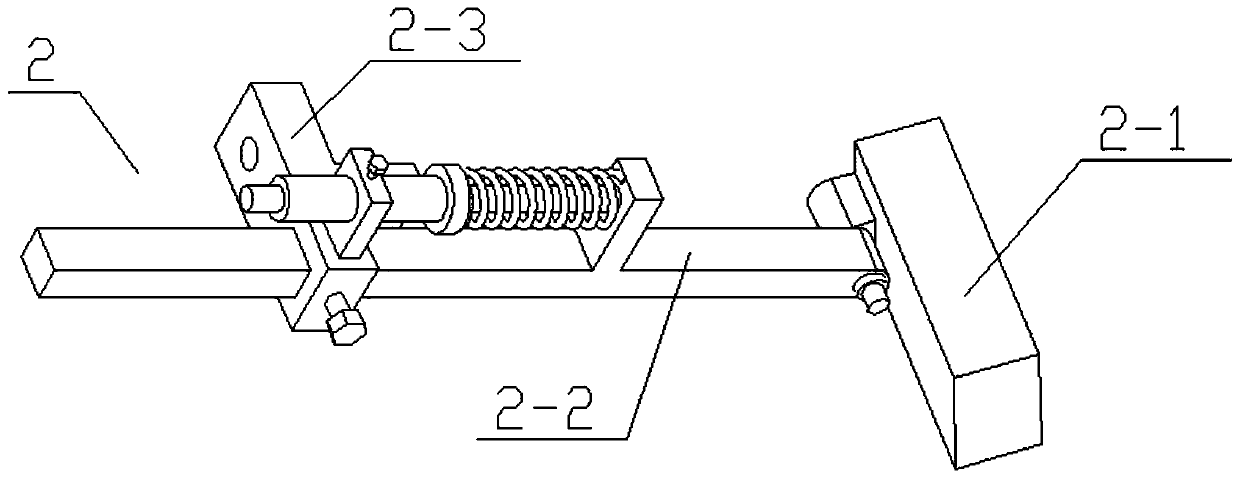

[0033] The unloading assembly I2 includes an unloading plate 2-1, a hinged shaft 2-1-1, a retaining ring 2-1-2, a cross bar 2-2, a circular rod seat 2-2-1, and a spring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com