Classification placement equipment for processing and manufacturing lithium batteries

A technology for processing and manufacturing lithium batteries, which is applied in the field of classification and placement equipment for processing and manufacturing lithium batteries, and can solve the problems of inconvenient movement and easy confusion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

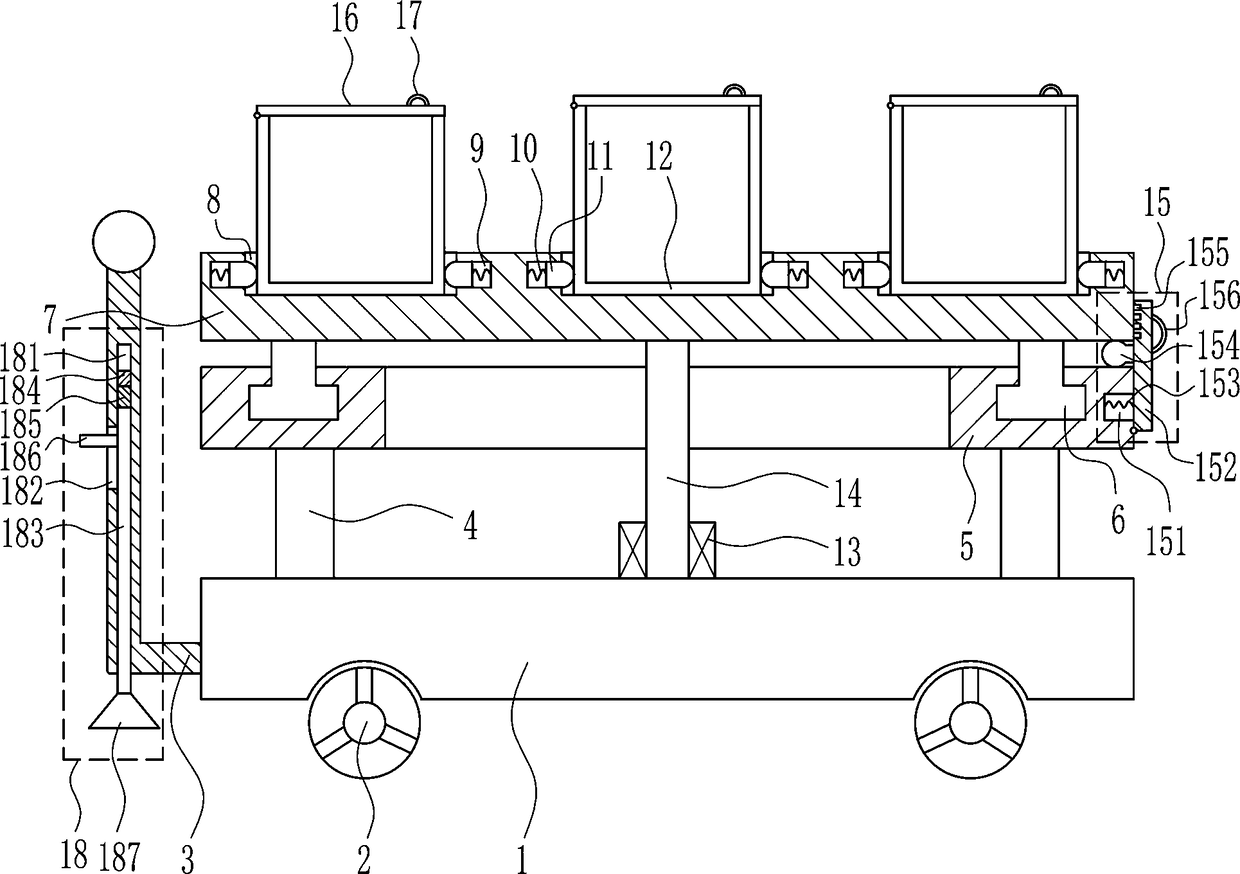

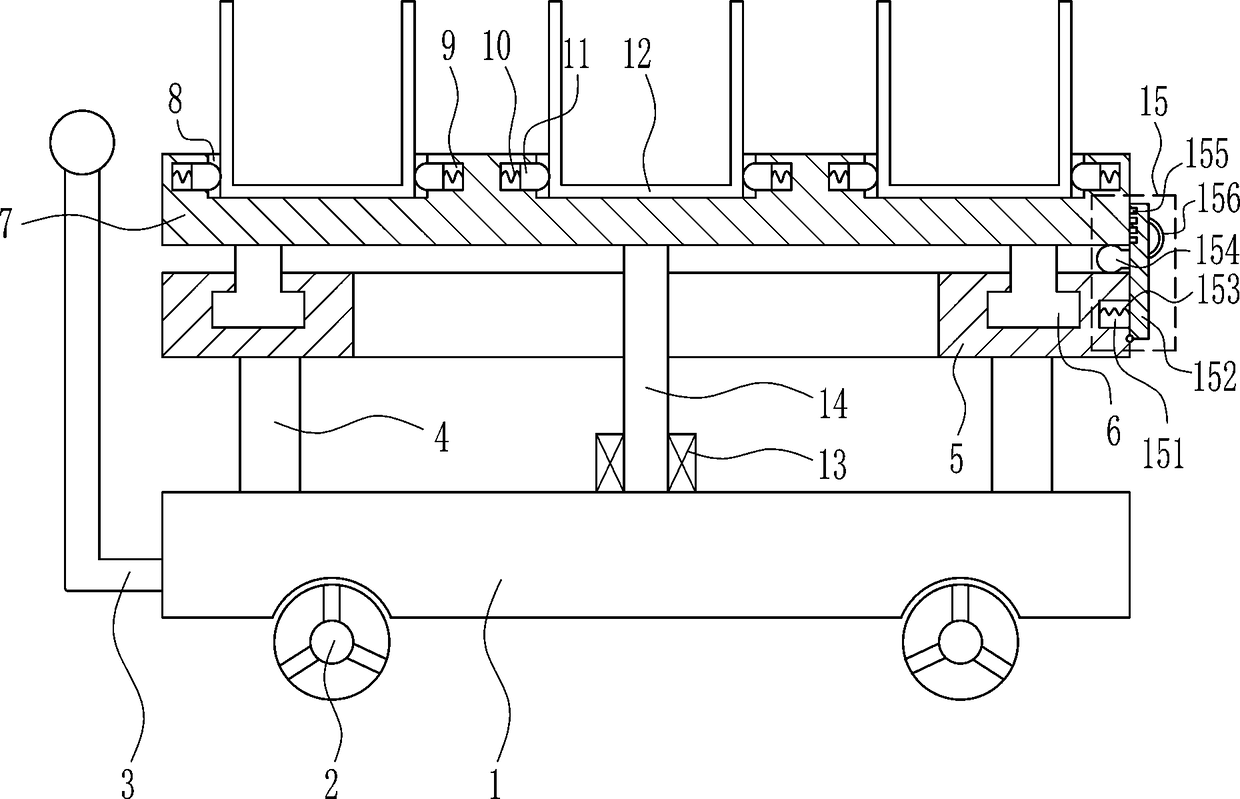

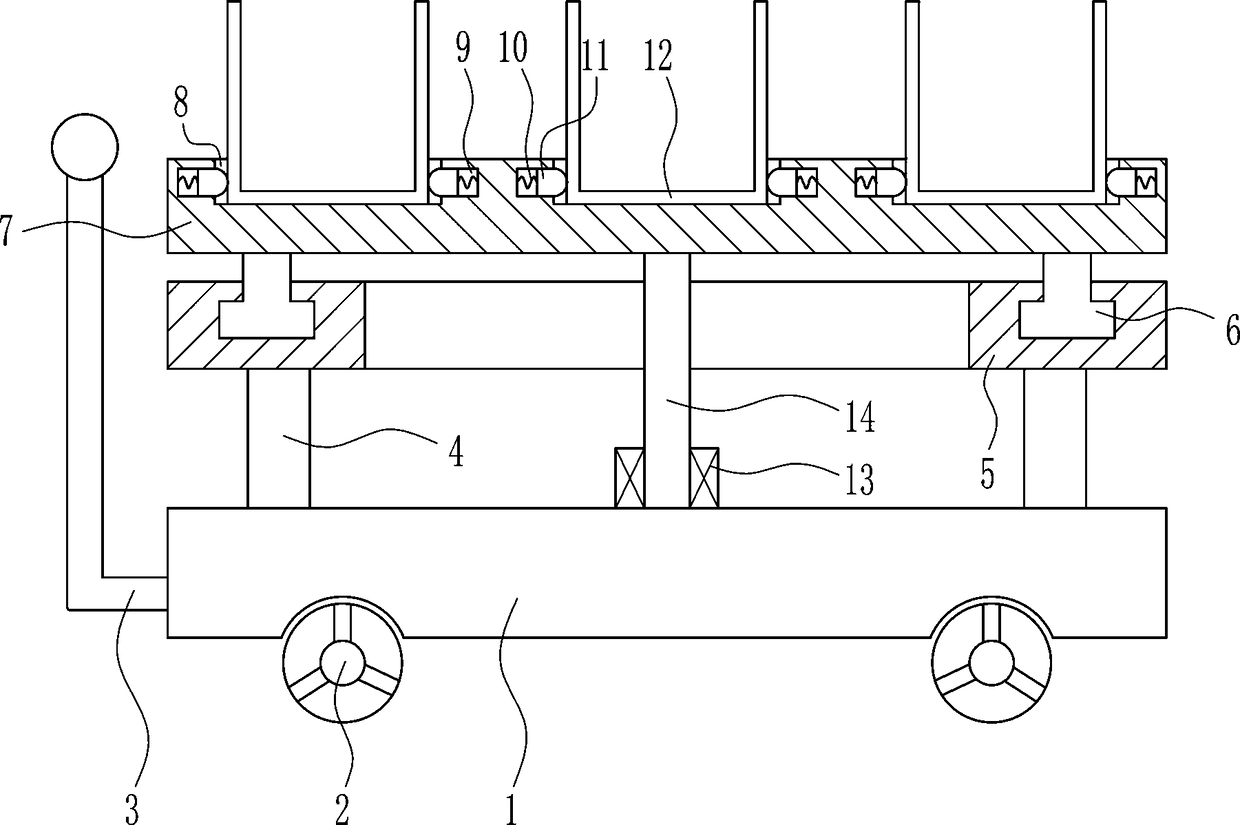

[0027] A sorting and placing device for lithium battery processing and manufacturing, such as Figure 1-5 As shown, it includes a mounting plate 1, a wheel 2, a push rod 3, a pole 4, an annular slide rail 5, a slider 6, a placement plate 7, a first spring 10, a rubber bump 11, a placement frame 12, and a bearing seat 13 and the rotating shaft 14, the bottom of the mounting plate 1 is equipped with wheels 2, the left side of the mounting plate 1 is connected with a push rod 3, the top of the mounting plate 1 is symmetrically provided with a strut 4, and the top of the strut 4 is connected with a circular slide rail 5, and the circular slide rail The left and right symmetrical slides in the 5 are connected with a slider 6, the top of the slider 6 is connected with a placement plate 7, and the outside of the top of the placement plate 7 is uniformly provided with a placement groove 8, and the middle part of the left and right walls of the placement groove 8 is provided with a firs...

Embodiment 2

[0029] A sorting and placing device for lithium battery processing and manufacturing, such as Figure 1-5 As shown, it includes a mounting plate 1, a wheel 2, a push rod 3, a pole 4, an annular slide rail 5, a slider 6, a placement plate 7, a first spring 10, a rubber bump 11, a placement frame 12, and a bearing seat 13 and the rotating shaft 14, the bottom of the mounting plate 1 is equipped with wheels 2, the left side of the mounting plate 1 is connected with a push rod 3, the top of the mounting plate 1 is symmetrically provided with a strut 4, and the top of the strut 4 is connected with a circular slide rail 5, and the circular slide rail The left and right symmetrical slides in the 5 are connected with a slider 6, the top of the slider 6 is connected with a placement plate 7, and the outside of the top of the placement plate 7 is uniformly provided with a placement groove 8, and the middle part of the left and right walls of the placement groove 8 is provided with a firs...

Embodiment 3

[0032] A sorting and placing device for lithium battery processing and manufacturing, such as Figure 1-5 As shown, it includes a mounting plate 1, a wheel 2, a push rod 3, a pole 4, an annular slide rail 5, a slider 6, a placement plate 7, a first spring 10, a rubber bump 11, a placement frame 12, and a bearing seat 13 and the rotating shaft 14, the bottom of the mounting plate 1 is equipped with wheels 2, the left side of the mounting plate 1 is connected with a push rod 3, the top of the mounting plate 1 is symmetrically provided with a strut 4, and the top of the strut 4 is connected with a circular slide rail 5, and the circular slide rail The left and right symmetrical slides in the 5 are connected with a slider 6, the top of the slider 6 is connected with a placement plate 7, and the outside of the top of the placement plate 7 is uniformly provided with a placement groove 8, and the middle part of the left and right walls of the placement groove 8 is provided with a firs...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap