Telescopic suction pipe structure

A retractable straw technology, applied in the field of straws, can solve the problems of water spraying and scalding from straws, and achieve the effect of avoiding spraying and beautiful and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

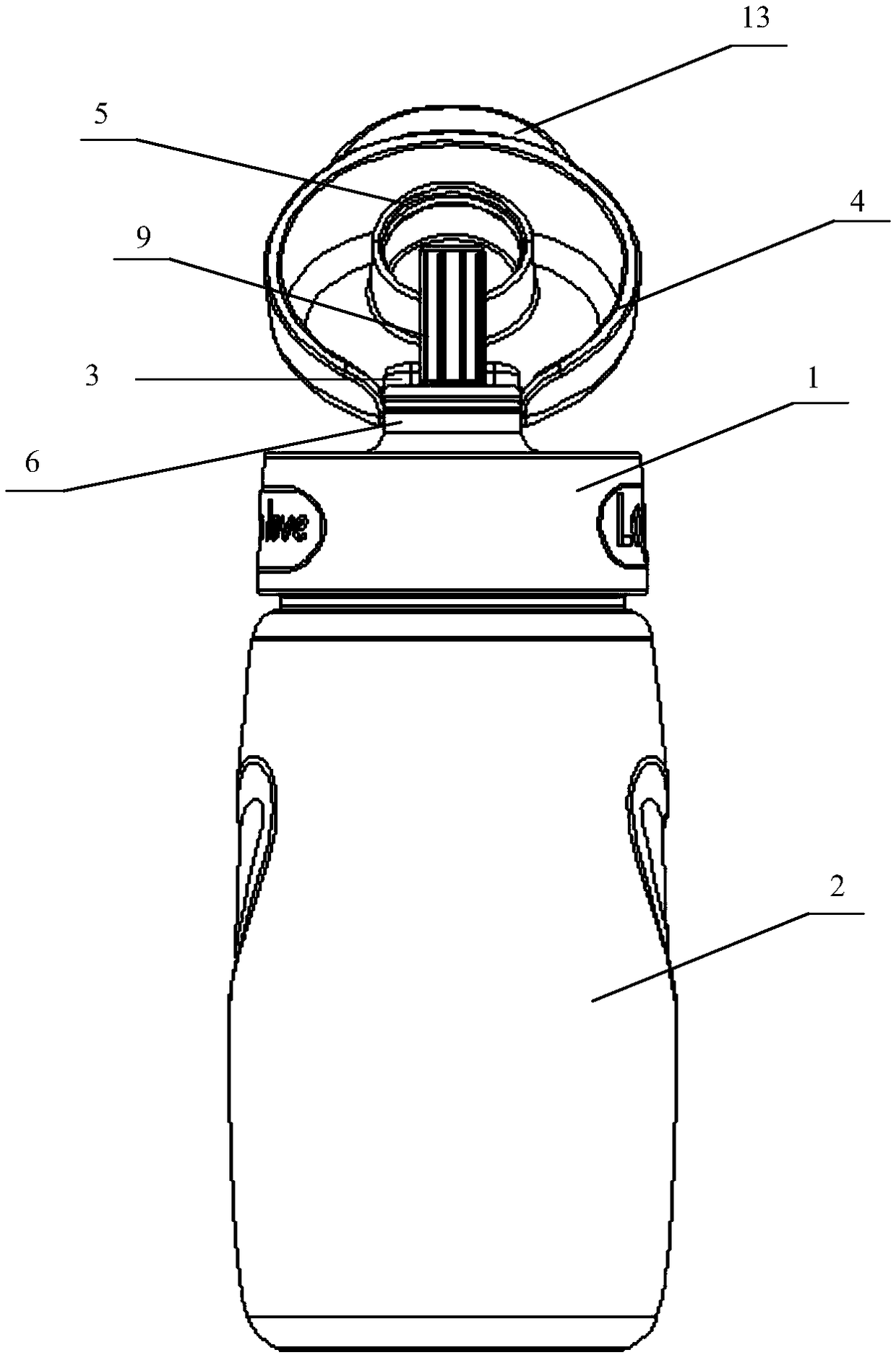

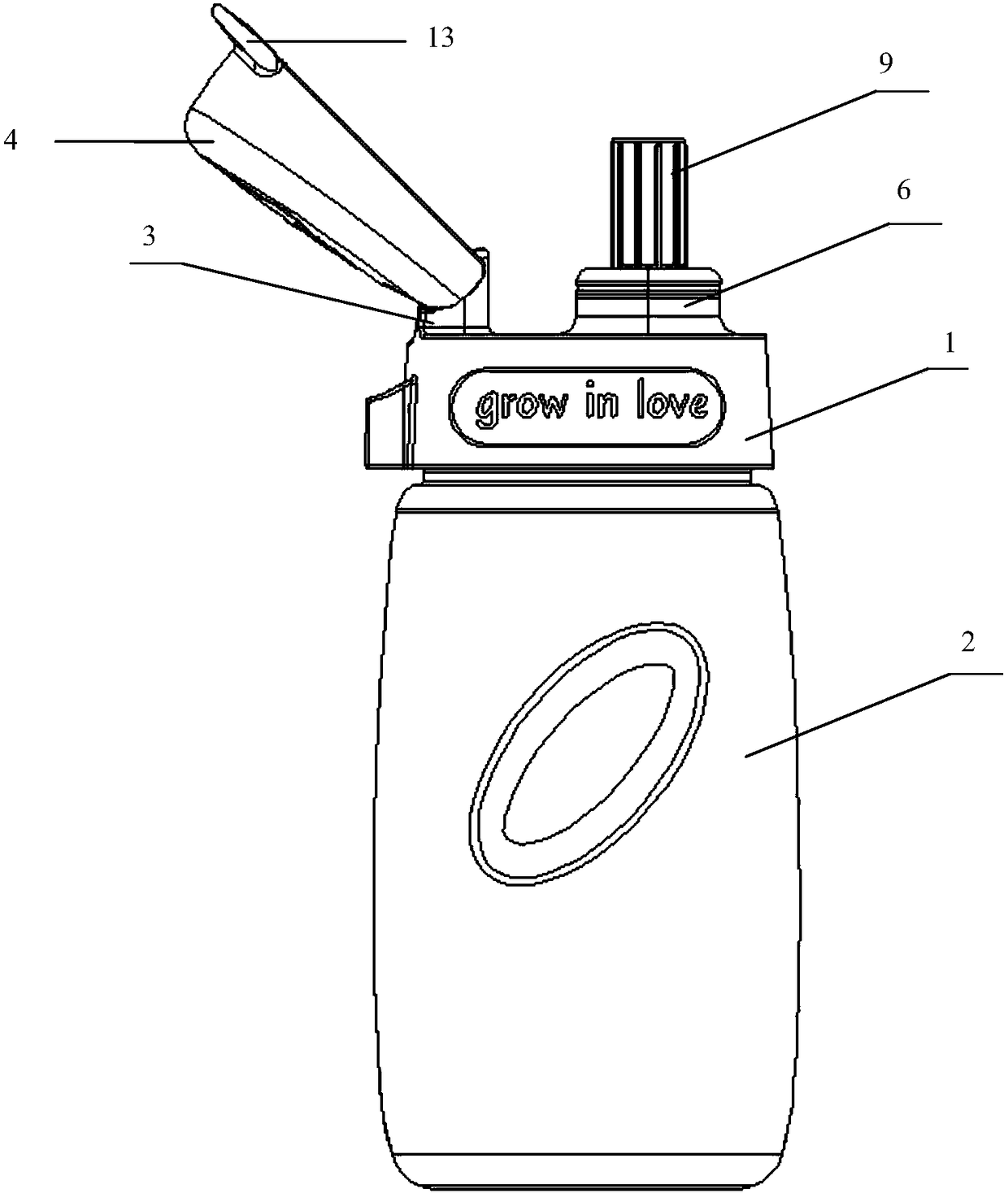

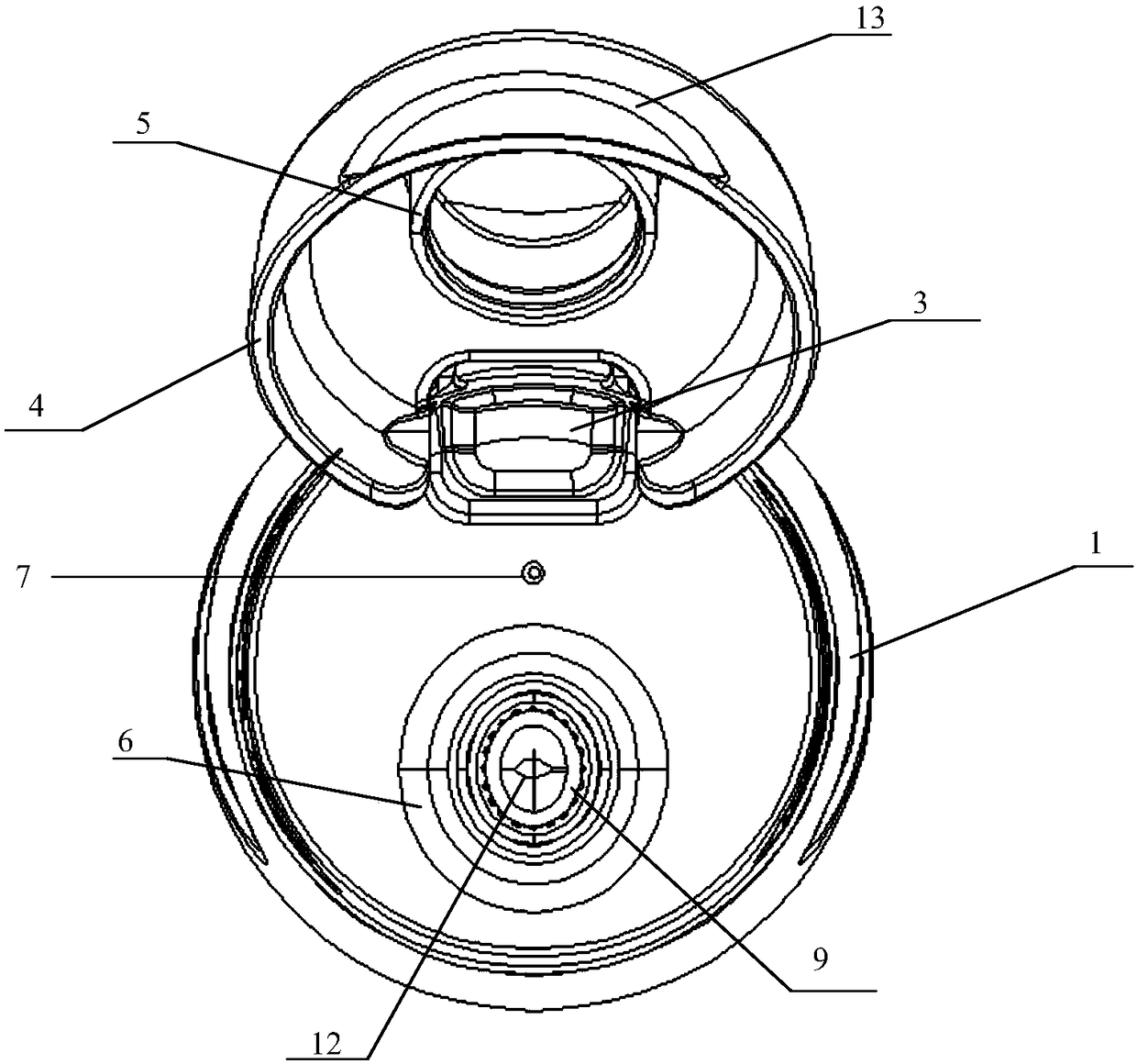

[0030] Such as Figure 1-6 The telescopic straw structure shown includes: an upper cover 1 , which removably covers the opening of the container 2 , and a rotating shaft 3 is provided at the upper end of the upper cover 1 .

[0031] A flip cover 4, the flip cover 4 is pivotally arranged on the rotating shaft 3 and can be pivoted to be opened and closed. The bottom of the flip cover 4 is provided with a sealing cover 5 extending downward. The flip cover cooperates with the upper cover to realize the basic structure of the flip container.

[0032] A hollow sealing cylinder 6, the sealing cylinder 6 vertically penetrates the upper cover 1 and its edge is higher than the plane where the upper cover 1 is located, when the flip cover 4 is closed, the sealing cover 5 is buckled with the opening above the sealing cylinder 6 seal. The sealing cylinder cooperates with the sealing cover to seal the suction pipe.

[0033] An air inlet 7, the air inlet 7 runs through the upper cover 1 a...

Embodiment 2

[0038] On the basis of embodiment 1, further, such as Figure 4 , 6 As shown, a sealing ring 10 is also included, and the sealing ring 10 is arranged between the upper cover 1 and the opening of the container 2 .

[0039] Further, the upper cover 1 is connected to the opening of the container 2 through a threaded structure.

[0040] Further, such as Figure 6 As shown, the air intake valve 8 and the suction pipe 9 are integrally formed. Since the air intake valve parts are small in size and are easy to lose, the integral molding of the air intake valve and the suction pipe can prevent the parts from being lost and can be integrally formed. Manufactured to reduce manufacturing costs.

[0041] Further, the intake valve 8 and the suction pipe 9 are made of silica gel. Such as Figure 6 As shown, in this embodiment, a laminated compression part is used, so the compression part is required to have good elasticity, and the silicone material has good elasticity and is safe and n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com