Buffer layer ink and preparation method thereof

A buffer layer and ink technology, applied in ink, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as limited blocking effect, component performance impact, electrical component electrical performance impact, etc., to achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The second aspect of the present disclosure: provide a method for preparing an ink for making a buffer layer of a flexible organic photovoltaic thin film device, including: epoxy resin glue, nano-zinc oxide and an organic solvent; wherein, the epoxy resin glue and nano-zinc oxide mixed with an organic solvent to obtain an ink; wherein, the concentration of the epoxy resin glue is 2-60mg / mL, and the concentration of the nano-zinc oxide is 5-75mg / mL; preferably, the concentration of the epoxy resin glue 5-40mg / mL, and the concentration of the nanometer zinc oxide is 10-50mg / mL.

[0036] According to the second aspect of the present disclosure, the organic solvent is well known to those skilled in the art. It is used to dissolve epoxy resin glue and disperse nano-zinc oxide. Generally, an organic solvent with a boiling point below 200°C is used, for example, it can be selected from methanol, At least one of ethanol, butanol, isopropanol, ethylene glycol methyl ether acetat...

Embodiment 1

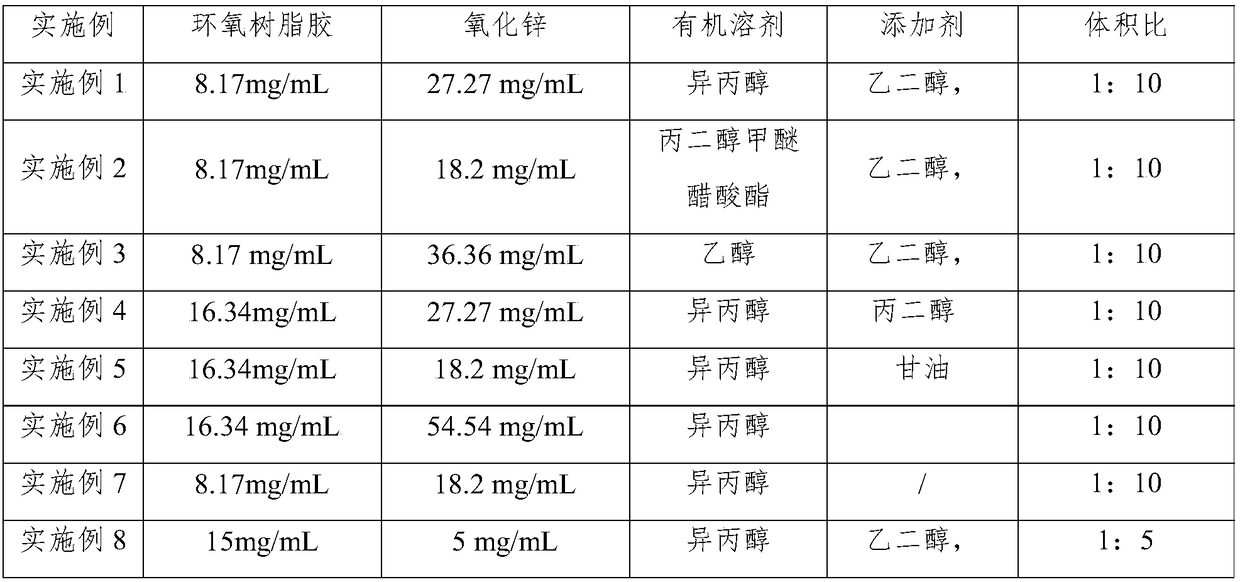

[0052] Weigh 90mg of epoxy resin glue and add it into 5mL reagent bottle A, measure 1mL isopropanol into reagent bottle A, stir to dissolve. Weigh 30mg of ZnO (particle size less than 10nm) into a reagent bottle, measure 1mL of isopropanol into reagent bottle B, and ultrasonically disperse under the condition of 10-60kHz for 5-30min. The solutions in reagent bottle A and reagent bottle B were mixed at a volume ratio of 1:10, ultrasonicated for 5 minutes, and then filtered with a 0.22 μm filter head to obtain ink. The specific composition is shown in Table 1.

[0053] Put the ink into the ink cartridge, and use an inkjet printer to stably eject the ink film. After heating and cross-linking at 120°C, a dense cross-linked film can be formed, which can prevent the penetration of the upper ink. The specific inkjet performance is shown in the table 2. The buffer layer made of this ink can meet the use standard, which can not only block the penetration of silver ink but also transmit...

Embodiment 2-8

[0055] The preparation steps of Examples 2-8 are basically the same as those of Example 1. The specific composition is shown in Table 1, and the specific properties of the ink are shown in Table 2. The buffer layer made by the ink prepared in Examples 2-8 can reach the use standard, and can block The penetration of the silver ink can in turn transport electrons.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com