Ink for making buffer layer, preparation method and application

A technology of buffer layer and ink, which can be applied in applications, inks, household appliances, etc., and can solve problems such as device leakage and penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The second aspect of the present disclosure provides a method for preparing an ink for making a buffer layer of a flexible organic light-emitting electrochemical cell, including: poly(vinyl cinnamate), poly(9,9-dioctylfluorene) and The polymer additive is mixed with an organic solvent to obtain an ink; wherein, the concentration of poly(vinyl cinnamate) in the ink is 5-40 mg / mL, and the concentration of poly(9,9-dioctylfluorene) is 0.5-5 mg / mL, the weight ratio of the polymer additive to the ink is 1-10% by weight; preferably, the concentration of poly(vinyl cinnamate) in the ink is 10-20mg / mL, poly(9,9 The concentration of -dioctylfluorene) is 1-3mg / mL, the weight ratio of the polymer additive to the ink is 3-6% by weight, and the weight average molecular weight of the polymer additive is 10000-50000.

[0031] According to the second aspect of the present disclosure, the organic solvent is used to dissolve poly(vinyl cinnamate), poly(9,9-dioctylfluorene) and polymer a...

Embodiment 1

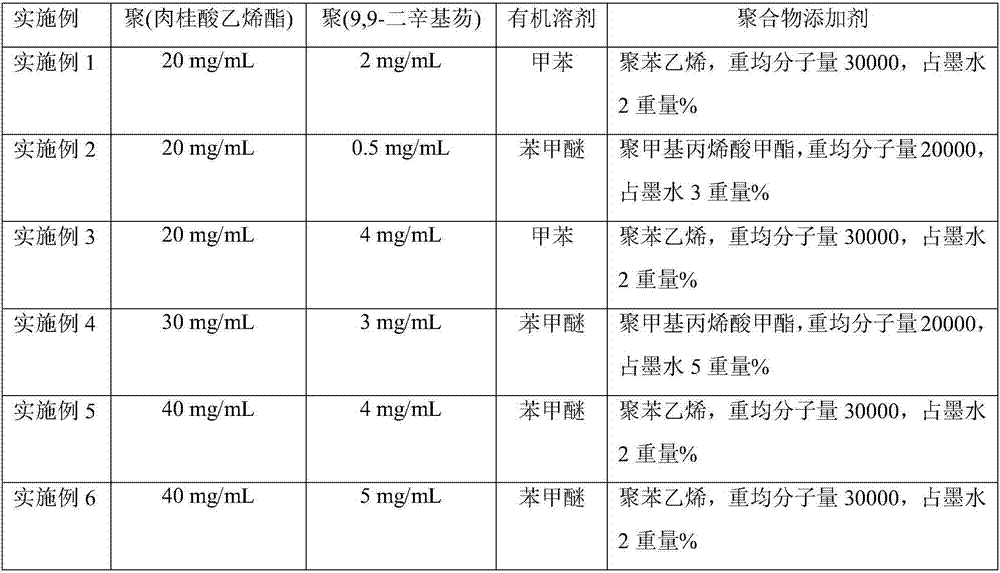

[0044] Weigh 20 mg of poly(vinyl cinnamate) and 2 mg of poly(9,9-dioctylfluorene) and transfer to a reagent bottle, add 1 mL of toluene, add 2 wt% ink weight of polystyrene, and magnetically stir for 1 hour , ultrasonicated at 40kHz for 5min, and then filtered with a 0.22μm filter head to obtain ink. The specific composition is shown in Table 1.

[0045] Put the ink into the ink cartridge, and use the inkjet printer to stably eject the ink film. After UV cross-linking, a dense cross-linked film can be formed, which can prevent the penetration of the upper ink. The specific performance of the ink is shown in Table 2. Using this The buffer layer made of ink can meet the standard of use, which can block the penetration of silver ink and transmit electrons.

Embodiment 2-6

[0047] The preparation steps of Example 2-6 are basically the same as in Example 1. The specific composition is shown in Table 1, and the specific performance of the ink is shown in Table 2. The buffer layer made by the ink prepared in Example 2-6 can reach the use standard, and can block The penetration of the silver ink can in turn transport electrons.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com