Size-adjustable detachable concrete mold

A concrete and easy-to-disassemble technology, applied in the direction of molds, etc., can solve the problems of increased cost, many influencing factors, poor demoulding effect, etc., and achieve the effects of improving work efficiency, improving versatility, and being practical and convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, and the content of the present invention is not limited to the following embodiments.

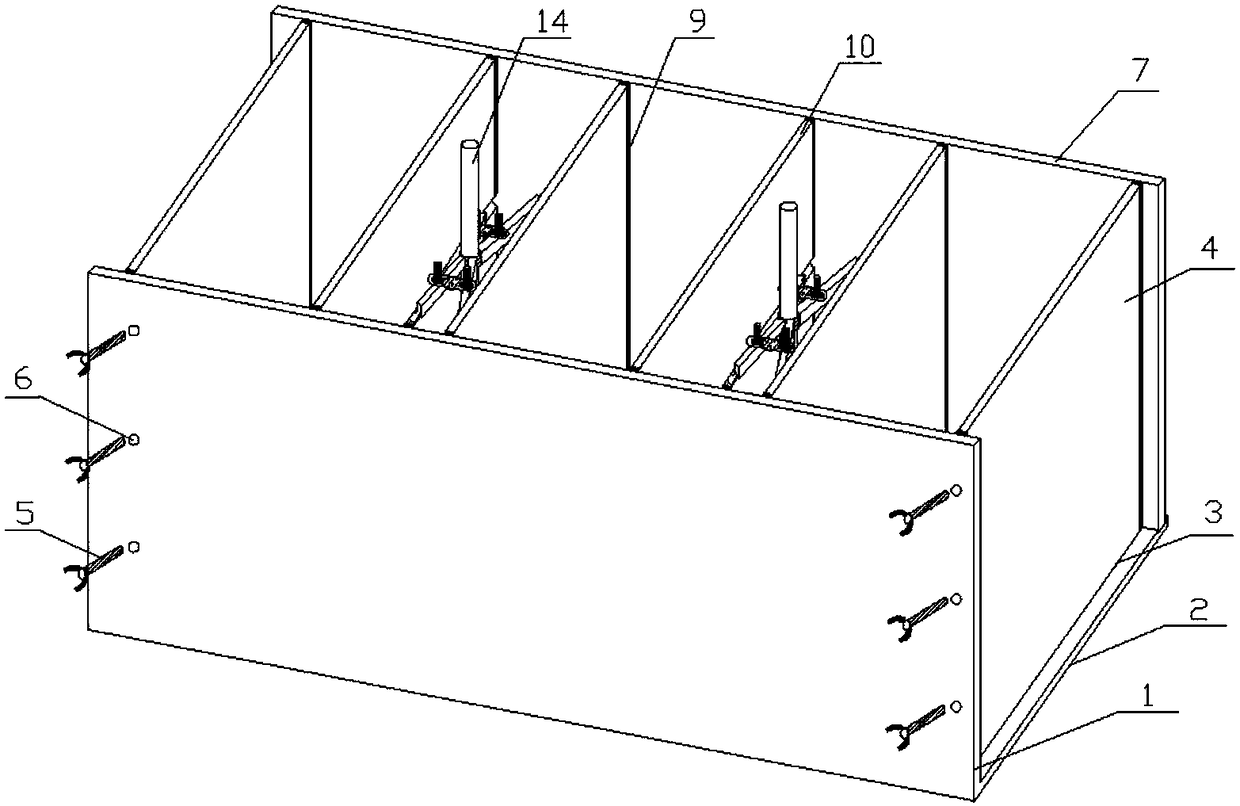

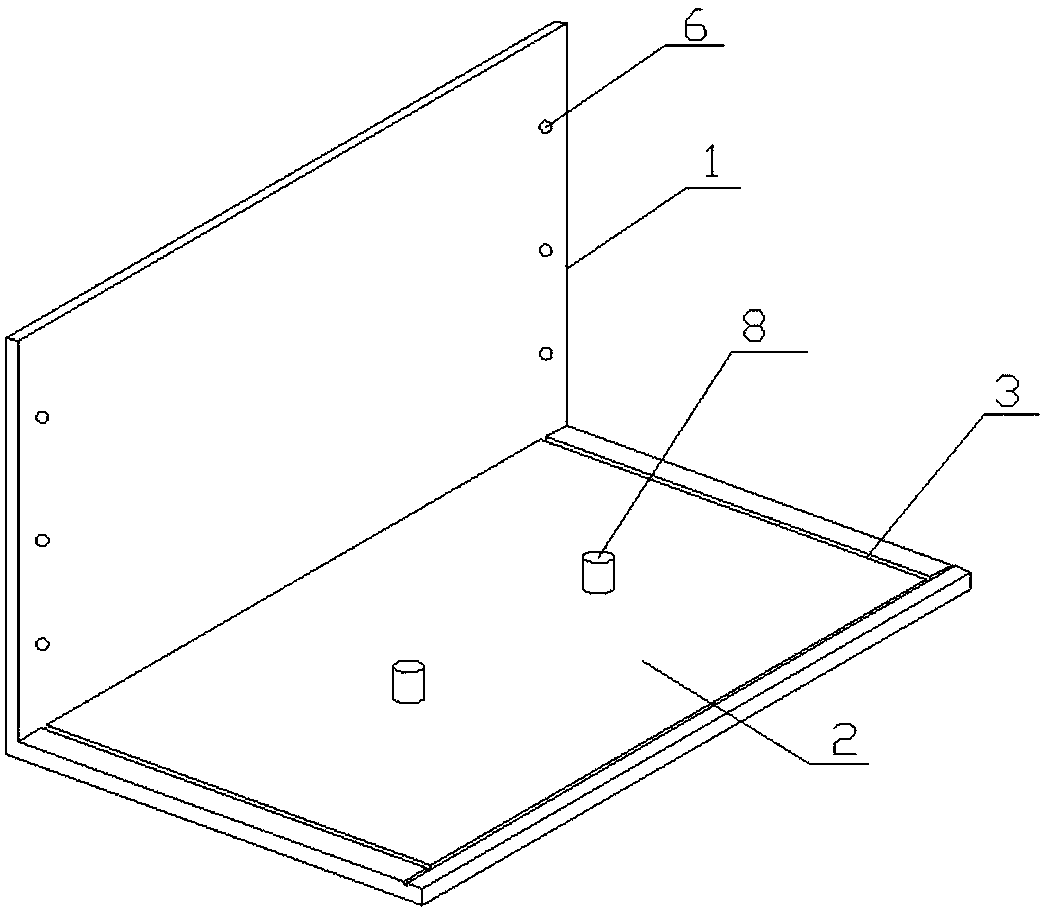

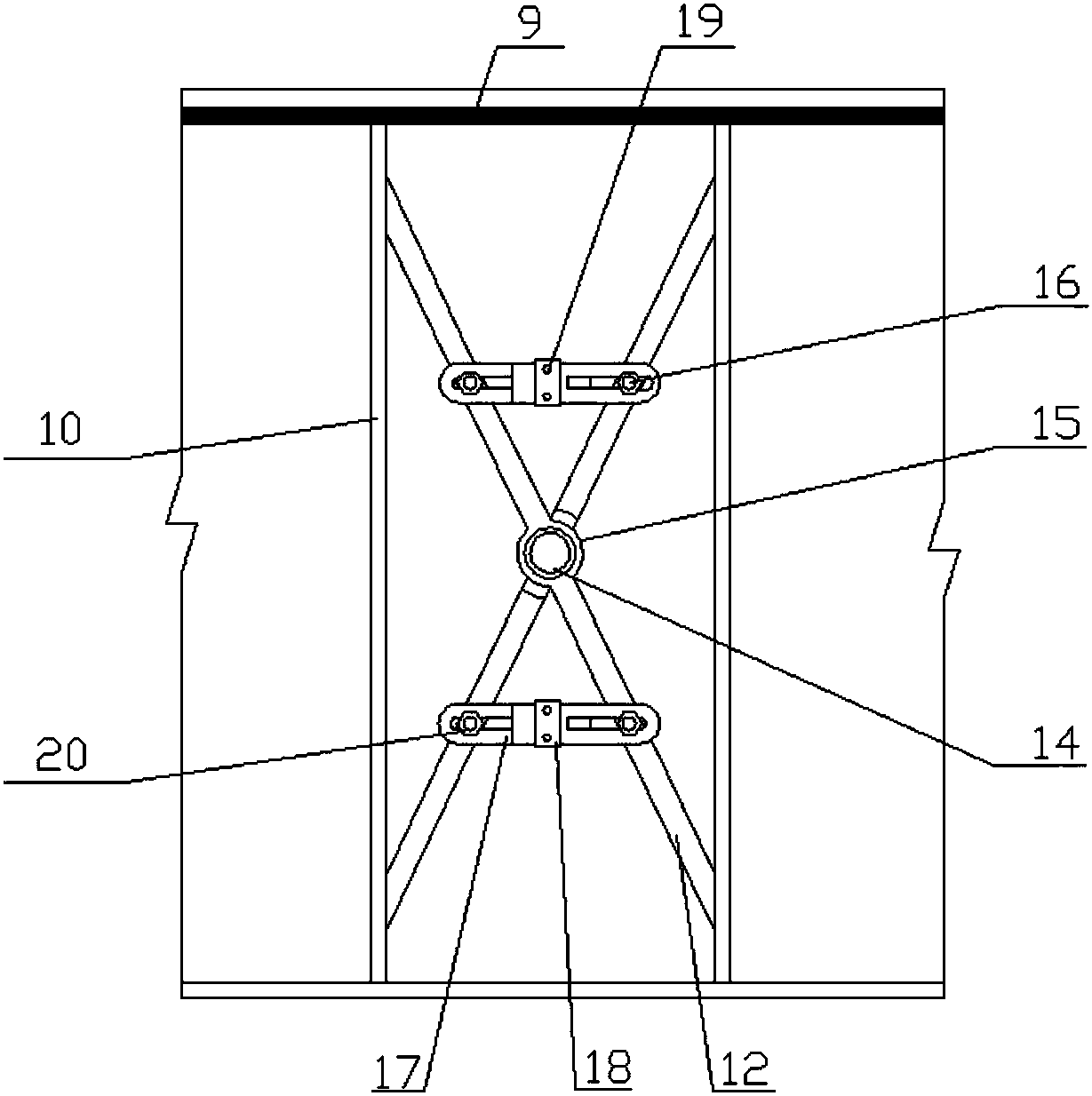

[0022] A size-adjustable and easy-to-disassemble concrete mold is characterized in that: side formwork Ⅰ1, bottom formwork 2, concave groove 3, end formwork 4, butterfly bolt 5, bolt hole 6, side formwork Ⅱ7, positioning pin 8, positioning The size adjustment device and the rubber film 9 are composed; the positioning pin 8 is tightly fixed on the bottom template 2, and the upper end is provided with an internal thread, the side template I1 and the long side direction of the bottom template 2 are integral, and the rest of the bottom template 2 The three sides are provided with concave grooves 3, the side template II7 is inserted into the concave groove 3 in the long side direction of the bottom template 2, the end template 4 is inserted into the concave groove 3 in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com