High-performance visible-light long-focal-length lens

A technology with visible light and long focal length, applied in optics, optical components, instruments, etc., can solve the problems of difficult to meet the requirements of spectral width, poor aspheric surface manufacturability, low cost performance, etc., to reduce the influence of chromatic aberration, good manufacturability, and improve imaging quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

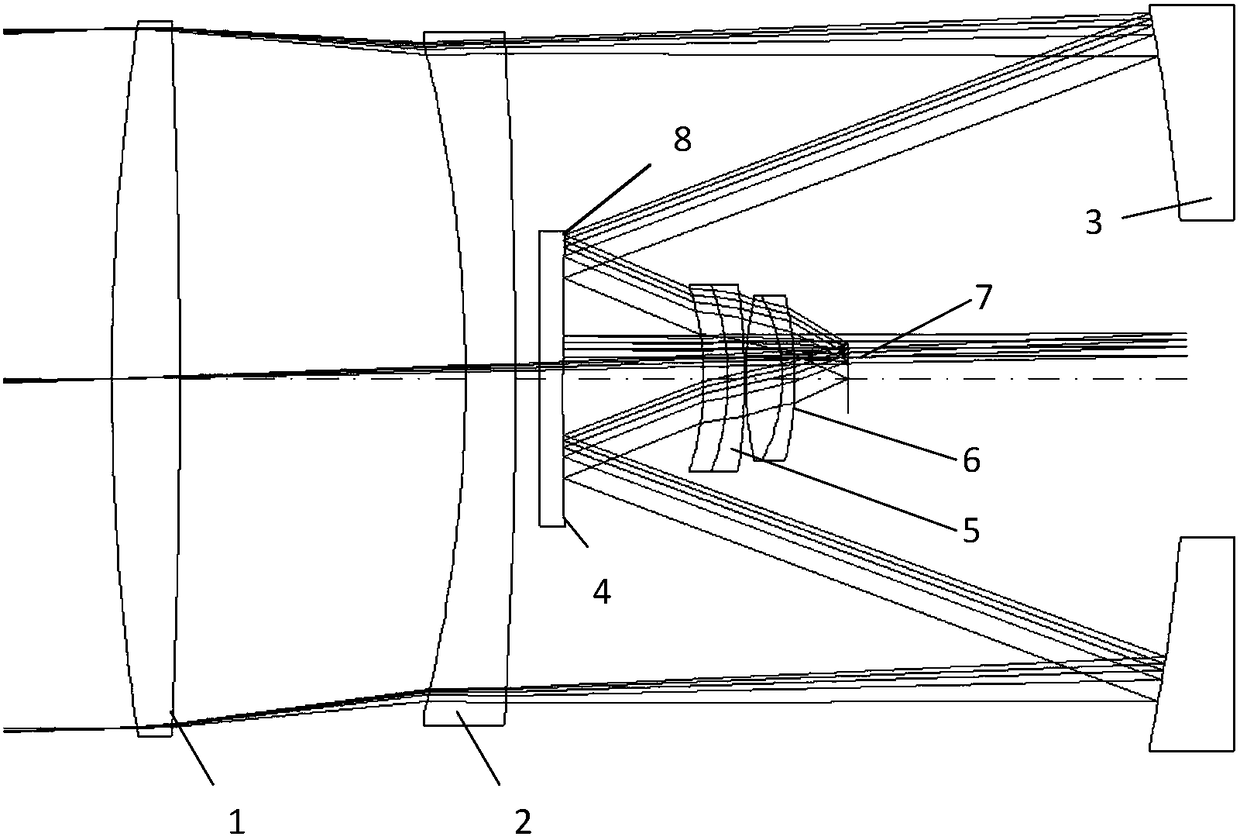

[0033] Such as figure 1 The 530mm high-performance long-focus lens optical system shown adopts 6 groups of 8-element catadioptric structure, including the first front fixed group 1, the second front fixed group 2, the primary reflector 3, the secondary reflector 4, and the aperture stop 8. The first post-fixation group 5 and the second post-fixation group 6;

[0034] The first front fixing group 1, the second front fixing group 2 and the main reflector 3 are sequentially arranged along the direction of the outgoing visible light beam;

[0035] The secondary reflector 4, the first rear fixed group 5, and the second rear fixed group 6 are arranged between the second front fixed group 2 and the main reflector 3, and the secondary reflector 4, the first rear fixed group 5, the second rear The fixed group 6 is set in sequence; the aperture stop 8 is set at the front end of the outer edge of the mirror surface of the secondary reflector 4;

[0036] The first front fixed group 1 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com