Centering attached mechanism for rack and pinion steering gear

An additional mechanism, rack and pinion technology, applied to mechanical steering gears and other directions, can solve the problems of difficulty in installing the steering wheel to ensure rack alignment, steering wheel misalignment, lack of professional alignment equipment for maintenance, etc., to achieve the effect of simple and easy structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In the following, the additional centering mechanism of the rack and pinion steering gear of the present invention will be further described in conjunction with specific embodiments, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concept and technical solution of the present invention.

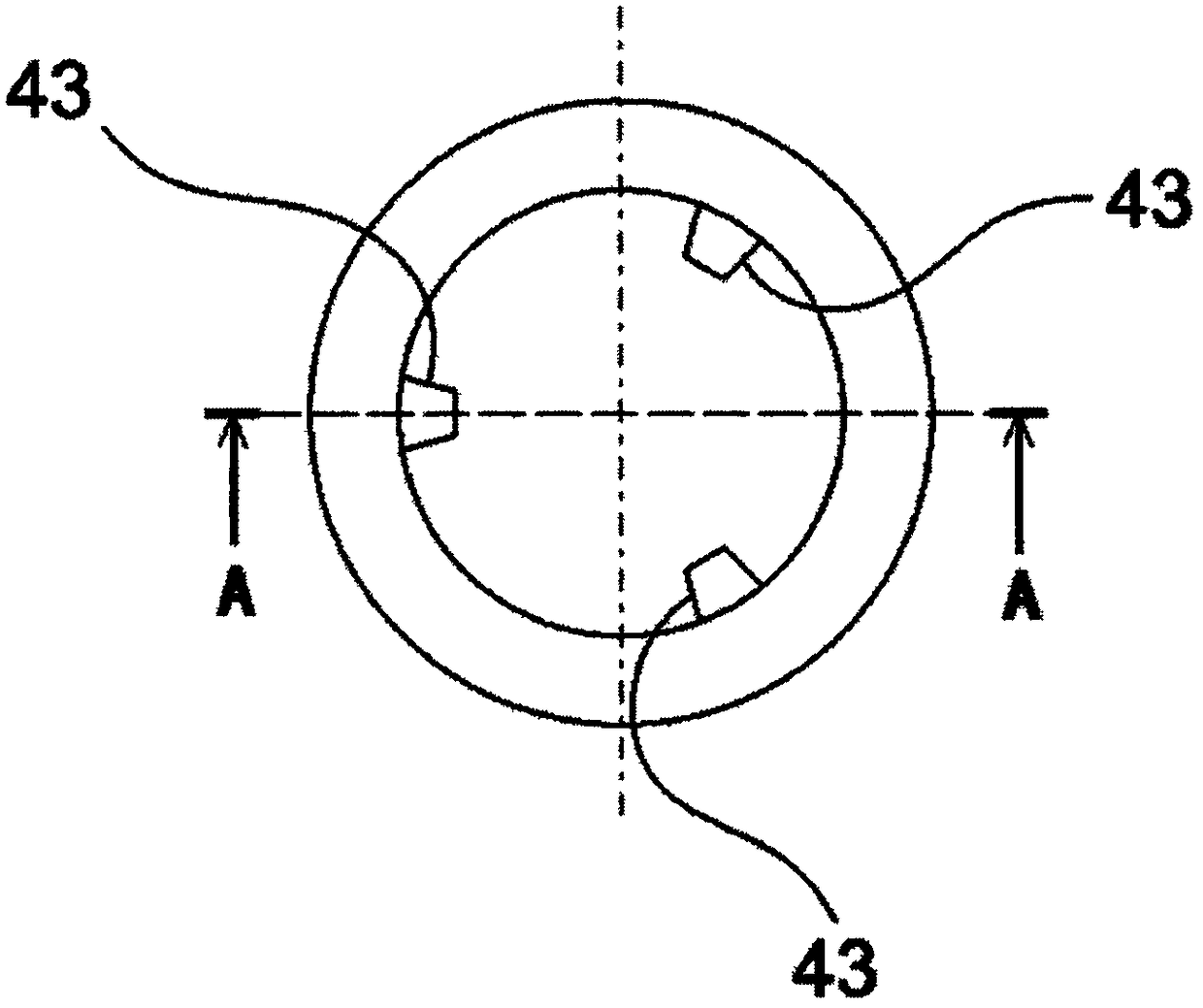

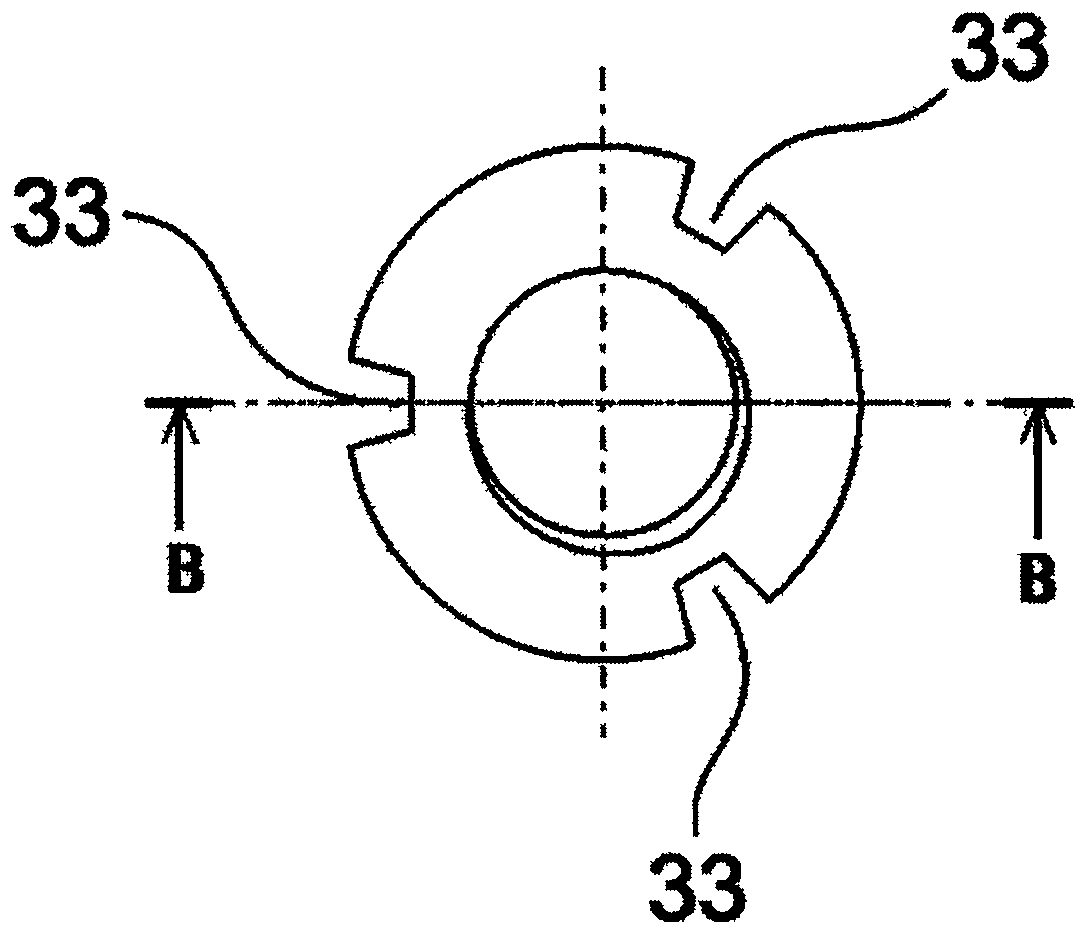

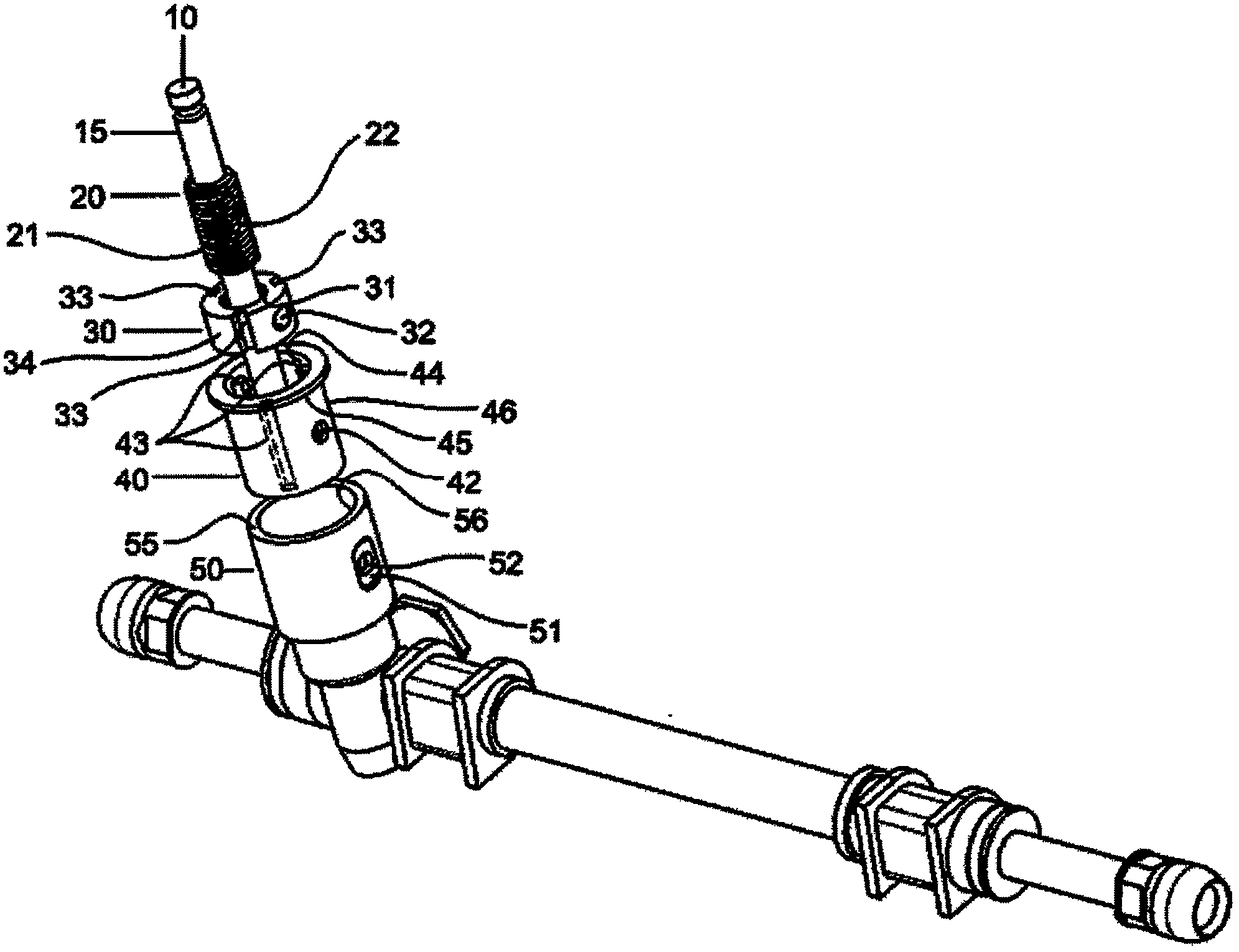

[0021] Such as figure 1 As shown, the additional centering mechanism of the rack and pinion steering gear of the present invention includes an external thread sleeve 20, an internal thread sliding sleeve 30 and a slide rail sleeve 40, and the length of the external thread sleeve 20 is greater than the length of the internal thread sleeve 30 . Such as Figure 6-7 As shown, the housing of the externally threaded sleeve 20 has an inner wall 25 that axially fits with the input shaft of the steering gear, and the outer wall of the housing is provided with an external thread 21 and is opened to communicate with the inner wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com