Winch rope releasing mechanism

A winch and handle technology, applied in the direction of the spring mechanism, the hoisting device, etc., can solve the problems affecting the aesthetics of the rope guide, and achieve the effects of improving the aesthetics, simple operation, and uncomplicated structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

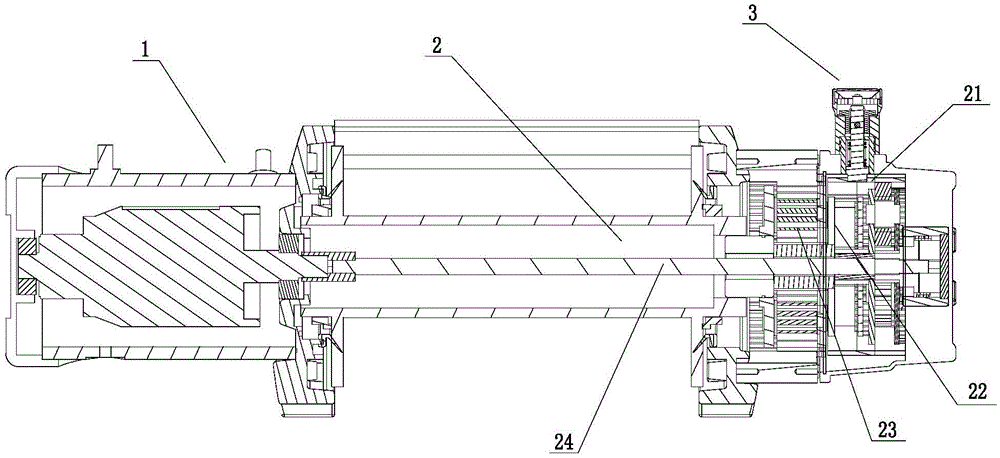

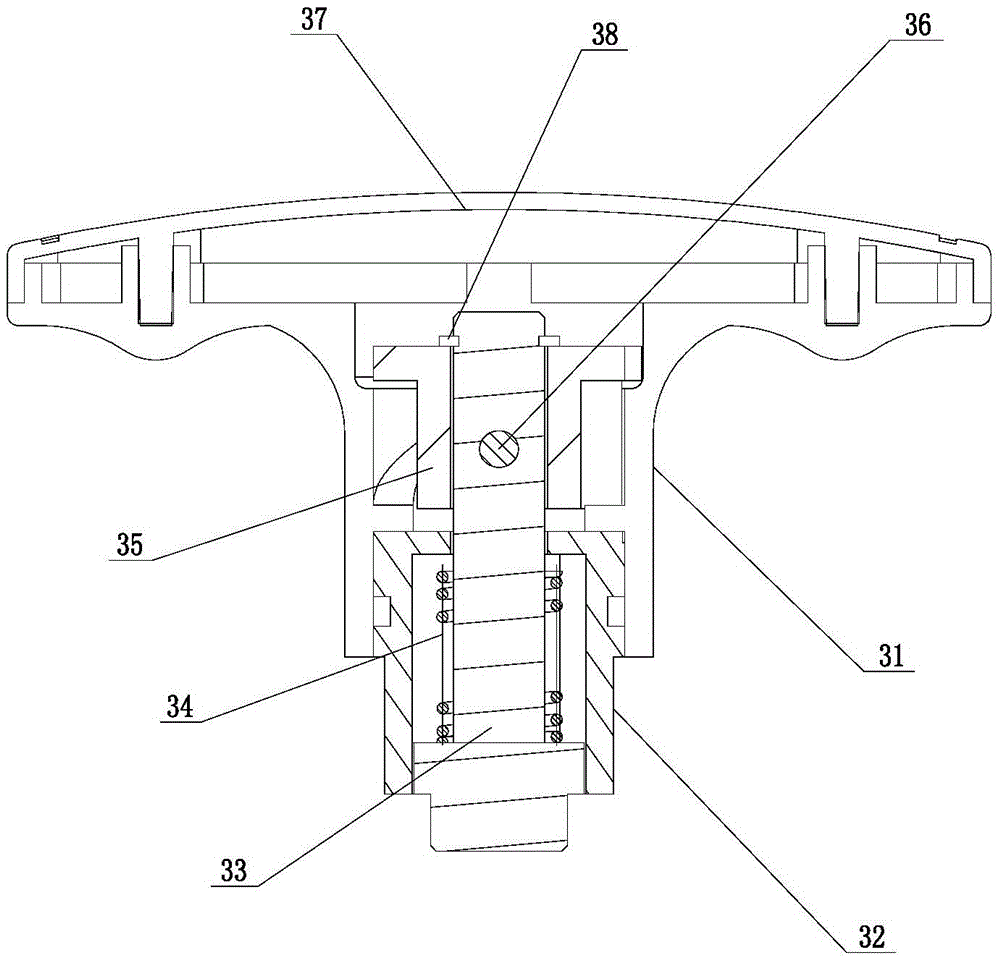

[0009] Example: such as Figure 1 ~ Figure 2 As shown, the present invention comprises mounting bracket, winch 2, winch motor 1 and handle 3, and winch 2 is installed on the described mounting frame, and winch motor 1 is installed on the described winch 2 and is used for driving described winch 2, and handle It is arranged above the winch 2; the handle 3 includes a handle bracket 31, a knob 35, a handle cover 32, a handle pin 33 and an elastic member 34, and the bottom of the handle bracket 31 is provided with a groove for passing through the handle pin 33 , the upper part of the handle pin 33 is set through the knob 35 and connected as a whole through the lateral penetration of the cylindrical pin 36, the lower part of the handle pin 33 is set through the handle cover 32, and the bottom of the handle cover 32 is concave to accommodate the elastic member 34 The annular groove, the elastic member 34 is sleeved on the handle pin 33 and placed in the annular groove, the bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com