Pleated skirt hemline pleating and sewing halter and pleated skirt hemline pleating and sewing method

A technique for pressing pleats and pleated skirts, which is applied to the field of pleated and stitched bridles at the hem of pleated skirts, can solve the problems of cumbersome steps, time-consuming and labor-intensive, etc., and achieves the effect of improving production efficiency and having a sense of hierarchy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below through specific embodiments.

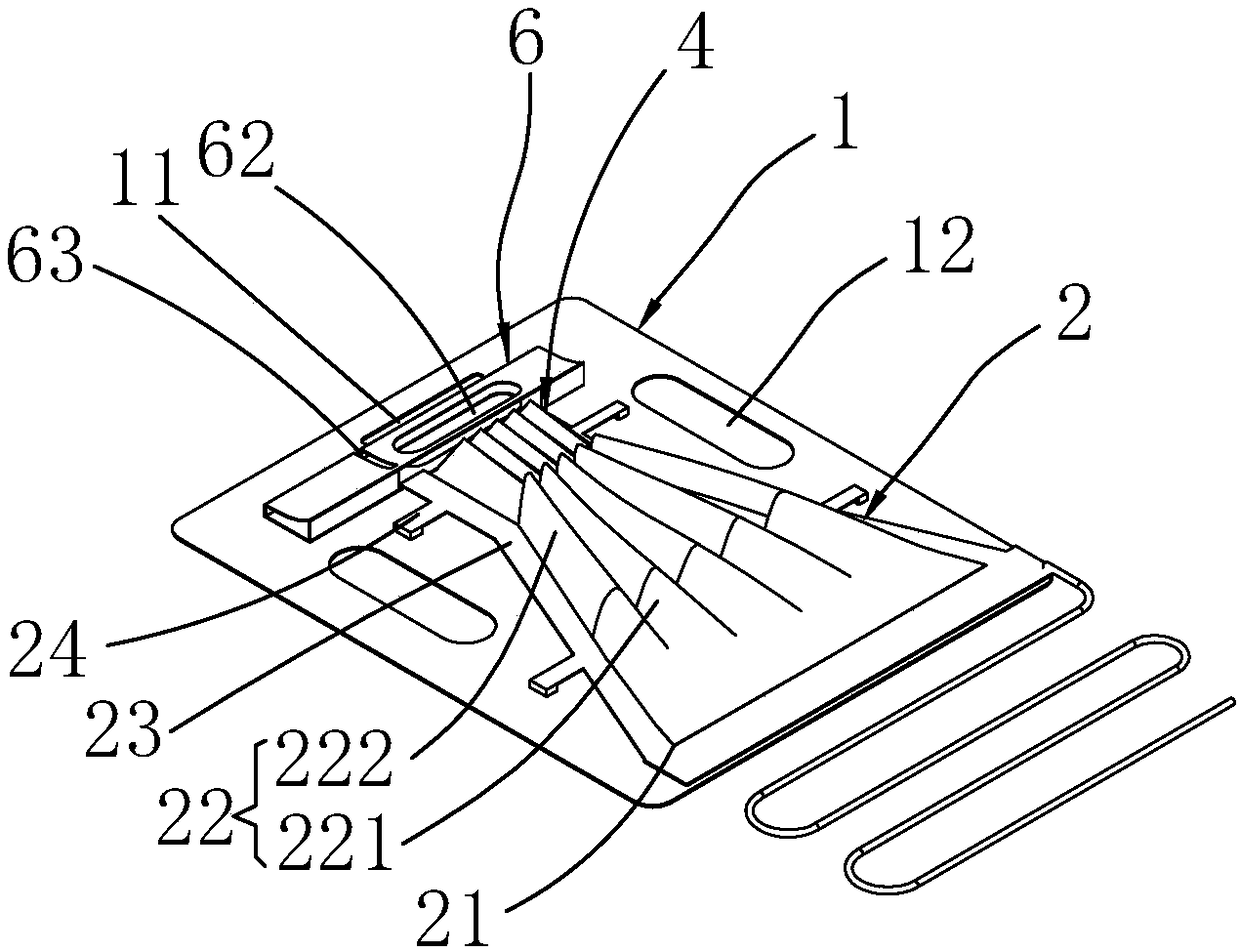

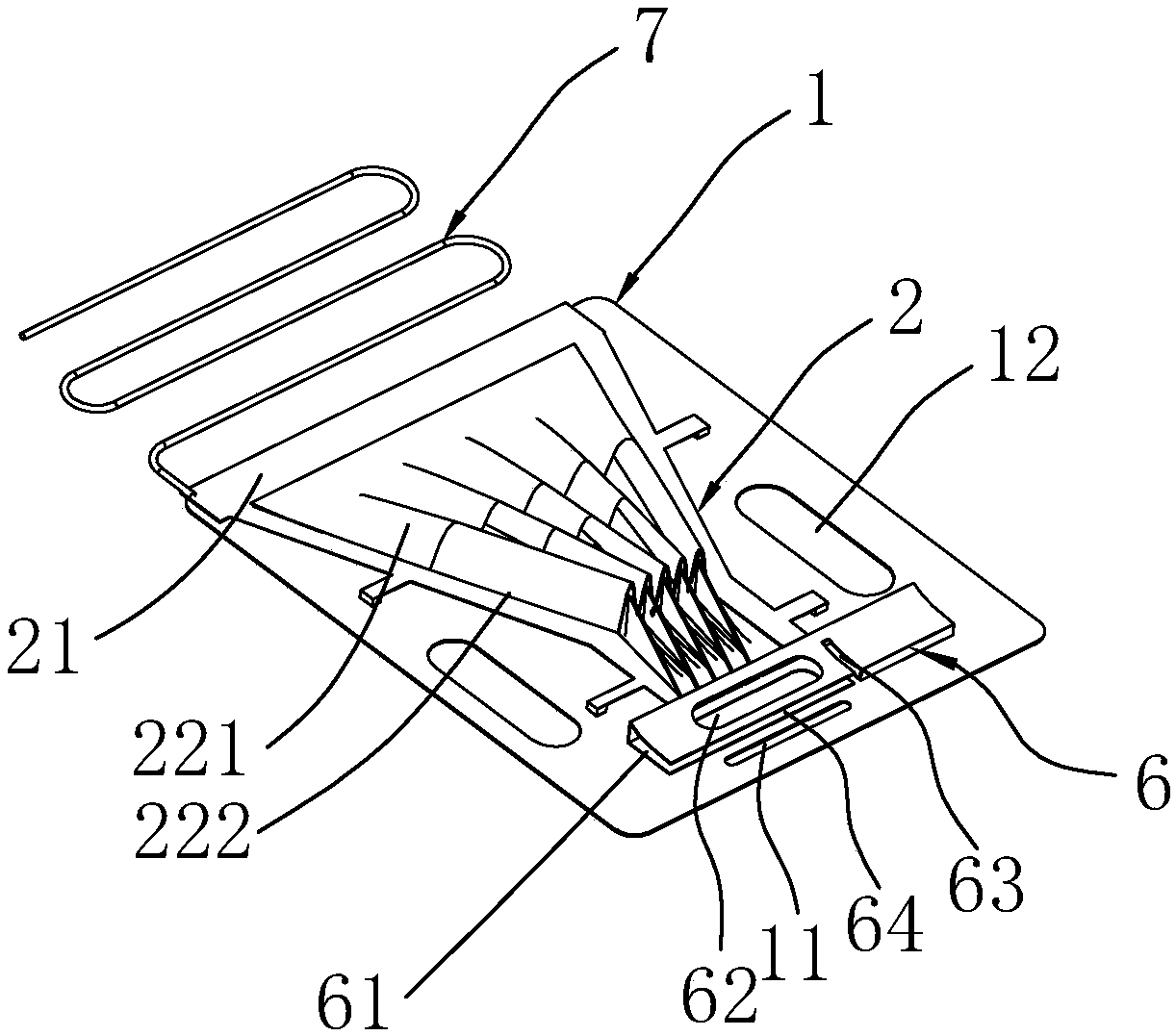

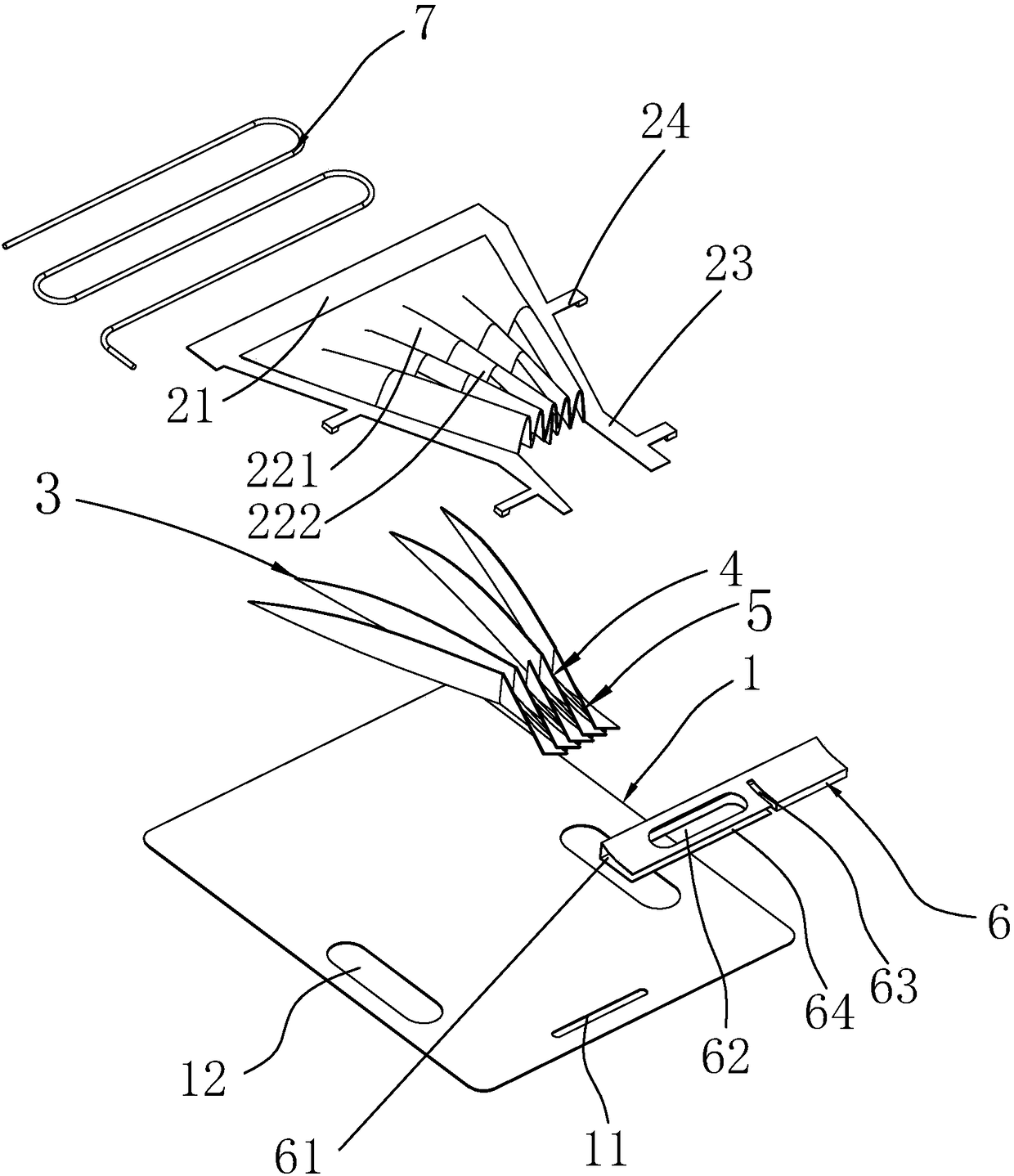

[0025] Such as Figure 1 to Figure 5 As shown, the pleated skirt pendant suture halter of the present invention includes a base plate 1 , a pleater 2 , a guide piece 3 , a side flap 4 , a trough guide rod 5 , a suture pipe 6 and a cloth guide rod 7 .

[0026] The crimping device 2 is fixed above the base plate 1. The crimping device 2 includes a fabric guide plate 21 and a wave plate 22 that are smoothly connected. The fabric guide plate 21 is close to the cloth inlet end of the crimping device 2, and the wave plate 22 is close to the crimping device 2 and the cloth is out. At the end, the fabric guide plate 21 is flat, and the wave plate 22 includes a smoothly connected gathering section 221 and a crimping section 222. The gathering section 221 is smoothly connected with the fabric guiding plate 21. The pleat section 222 is wave-shaped, the wavelength of the wave plate 22 gradually d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com