Automatic dripping test device

A technology of drip test and drip tube, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, can solve the problems that the test bench cannot adjust the angle of the table surface and cannot adapt to the test requirements, and achieves a high degree of automation and improves accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

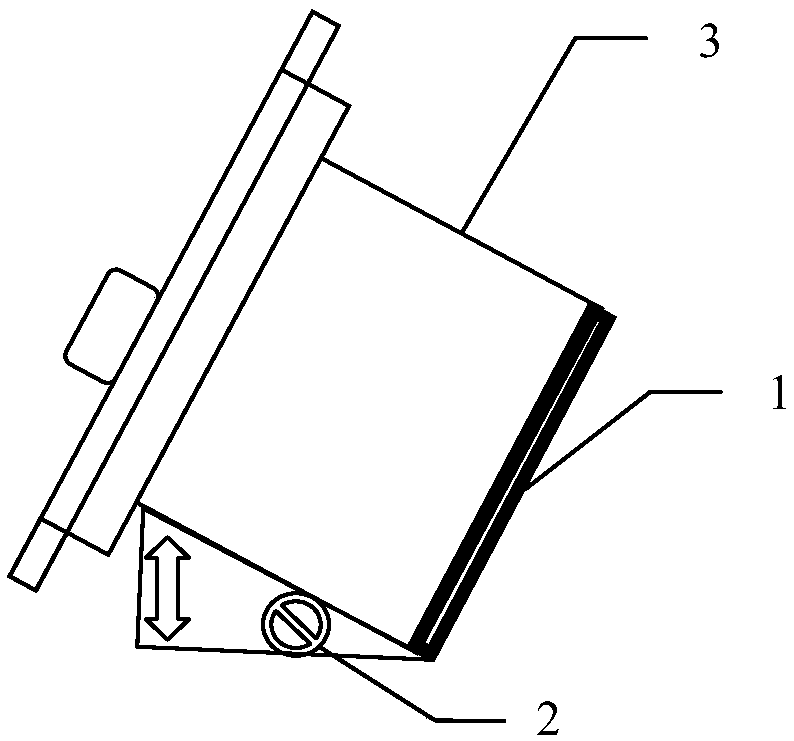

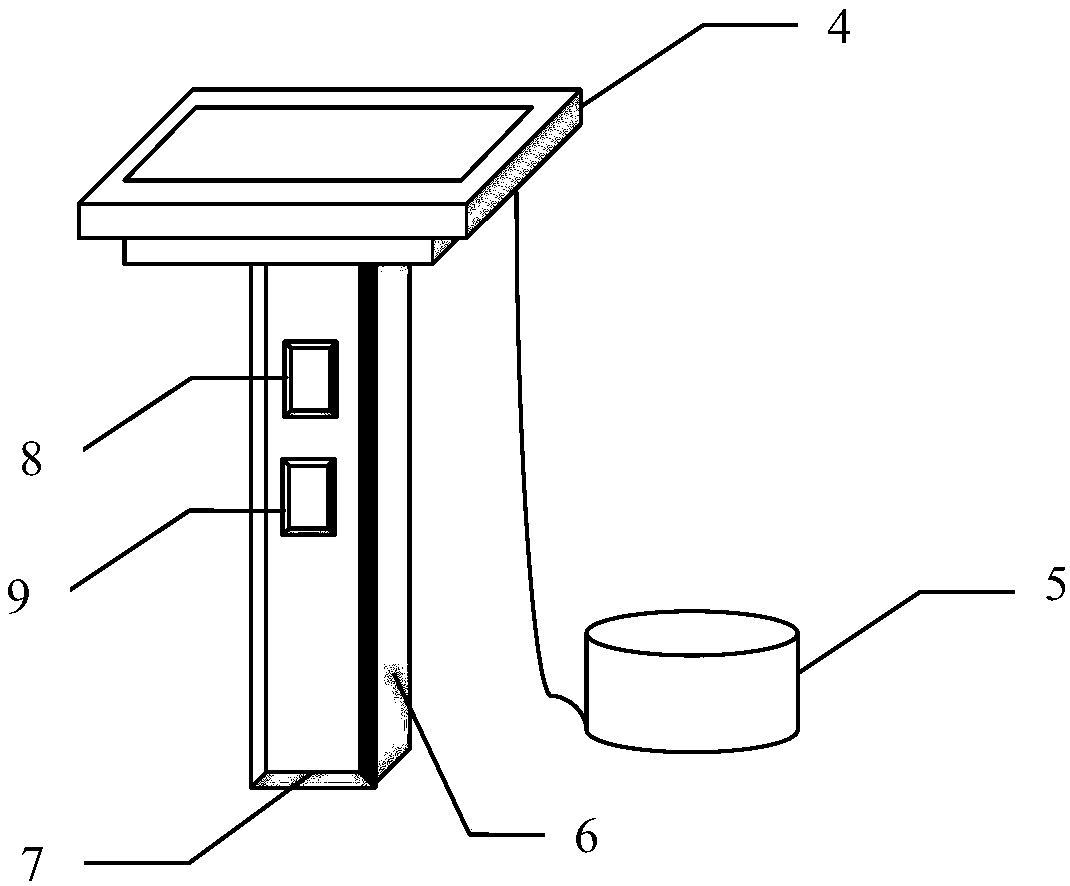

[0028] like Figure 1-Figure 4 As shown, the present embodiment provides an automatic drip test device, comprising: an adjustable sample rack for placing a sample 3 to be tested, including a sample rack body 1 and an angle regulator 2 for adjusting the inclination angle of the sample rack body; a dripping mechanism , suspended above the adjustable sample holder, used to generate water droplets for the sample to be tested, including a water collection assembly, a drip tube assembly and an electrical control box, and the drip tube assembly is respectively connected to the water collection assembly and the electrical control box. During the test, the collection The water in the water component drips onto the sample to be tested through the drip tube component under the control of the electrical control box.

[0029] In this embodiment, the sample holder body 1 includes a base and a side support plate connected to the base, and the angle adjuster 2 is arranged in the base to adjus...

Embodiment 2

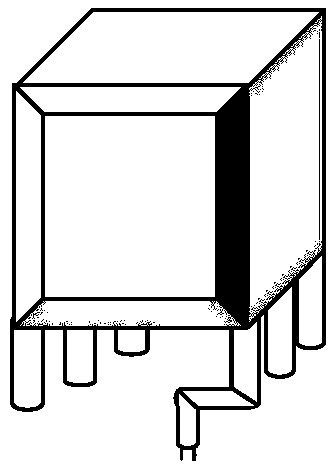

[0034] refer to Figure 1-Figure 4 As shown, the automatic drip test device provided in this embodiment also includes an airtight test box, the adjustable sample holder is arranged at the bottom of the airtight test box, and the water collecting assembly and the drip tube assembly are arranged at the top of the airtight test box.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com