Contacting device for contacting an electrical conductor to an electrical conductor path

A technology of printed circuit board and conduction device, applied in the field of contact conduction device, can solve problems such as labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

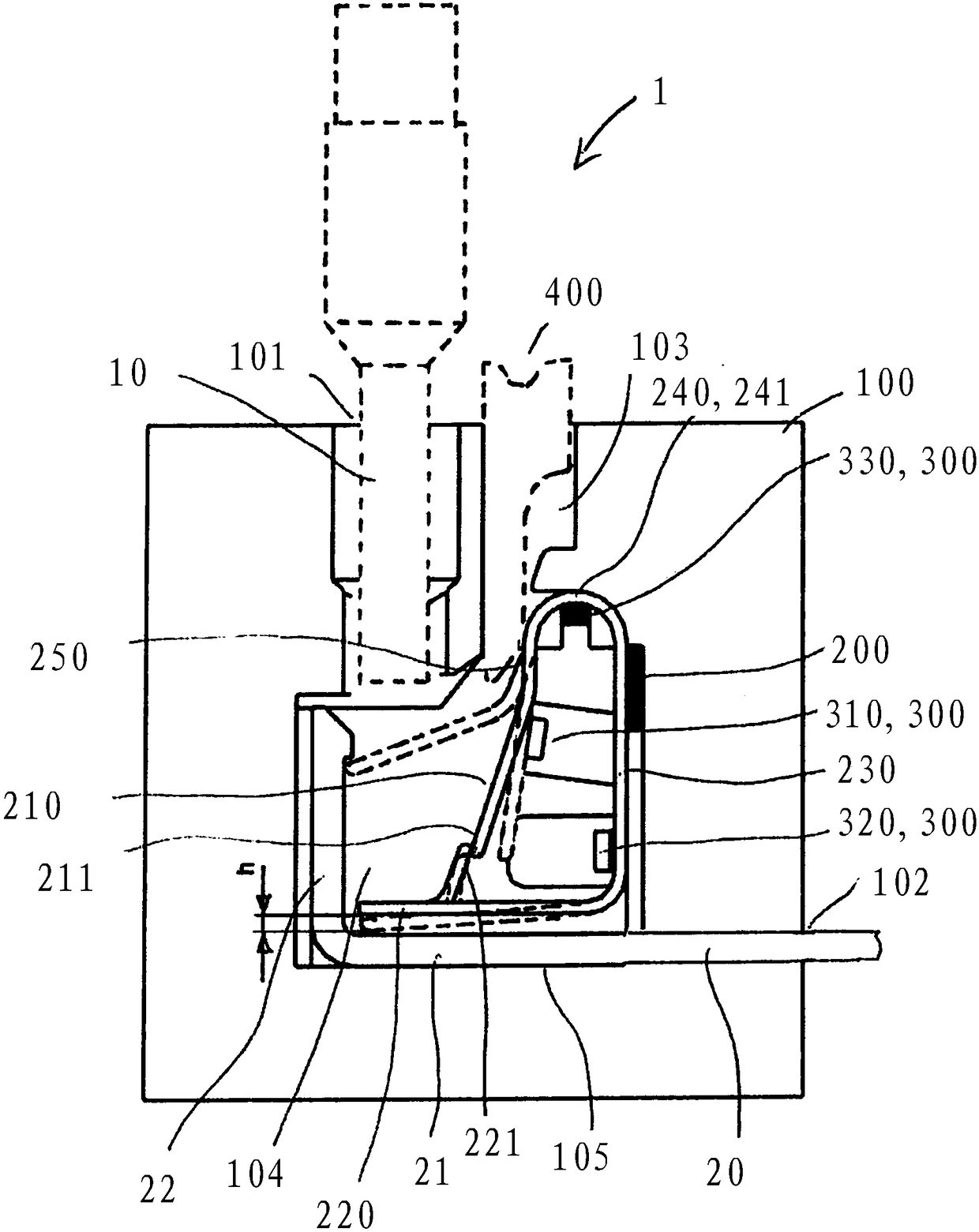

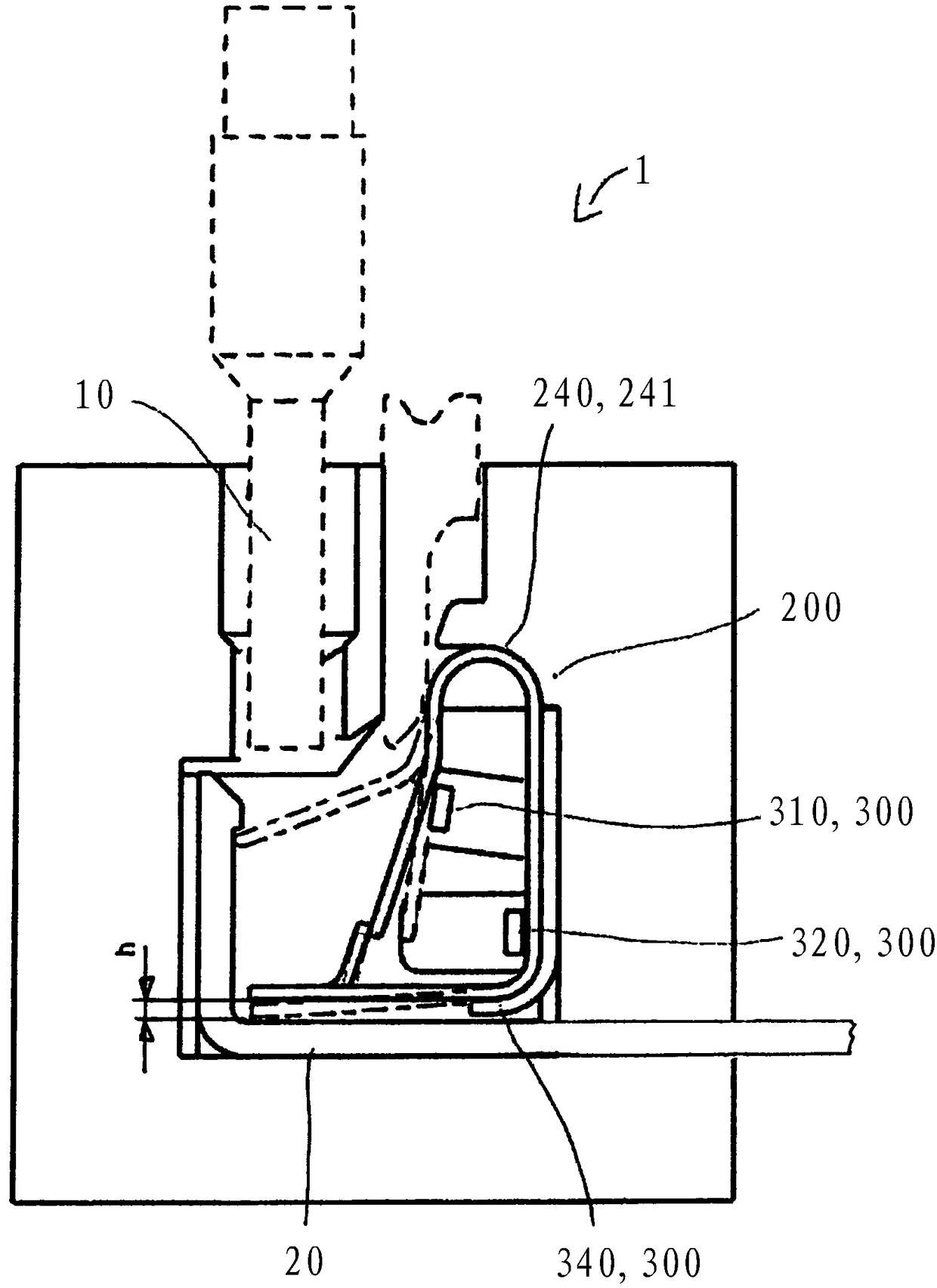

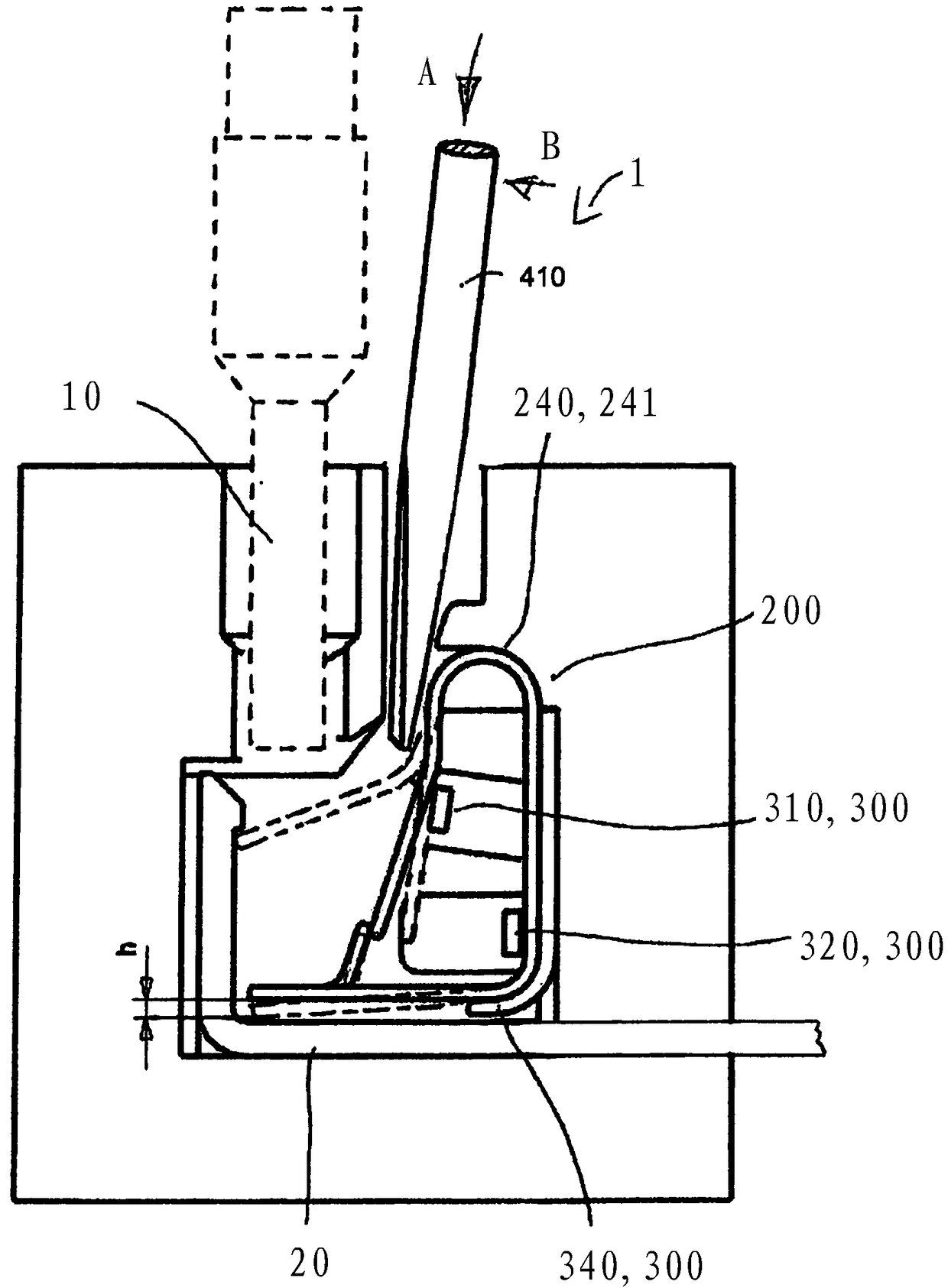

[0027] Figure 1A and 1B In each case a schematic view of a contacting device 1 for contacting an electrical conductor 10 to a printed circuit board 20 is shown, wherein in order to fix the electrical conductor on the printed circuit board, the electrical conductor is inserted into the contacting device Only a small amount of effort is required. The contacting device 1 comprises a housing 100 with a first opening 101 for inserting an electrical conductor 10 into a cavity 104 of the housing and a first opening 101 for inserting a printed circuit board 20 into the cavity 104 of the housing. the second opening 102 . The electrical conductor can be, for example, a busbar, by means of which electrical signals can be supplied to electrical devices, such as relays or circuit breakers. The contact conducting arrangement 1 comprises a contact bow 200 which is arranged in the cavity 104 of the housing 100 . The contact bow 200 has a first section 210 with a first end 211 for pressing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com