An automatic water supply system applied to concrete mixing station

An automatic water supply and concrete technology, applied in mixers, mixing plants, transportation and packaging, etc., can solve problems such as easy clogging of water outlets, contamination of mixer covers, and washing of mixing shafts, to increase material accuracy, prolong service life, Spray evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

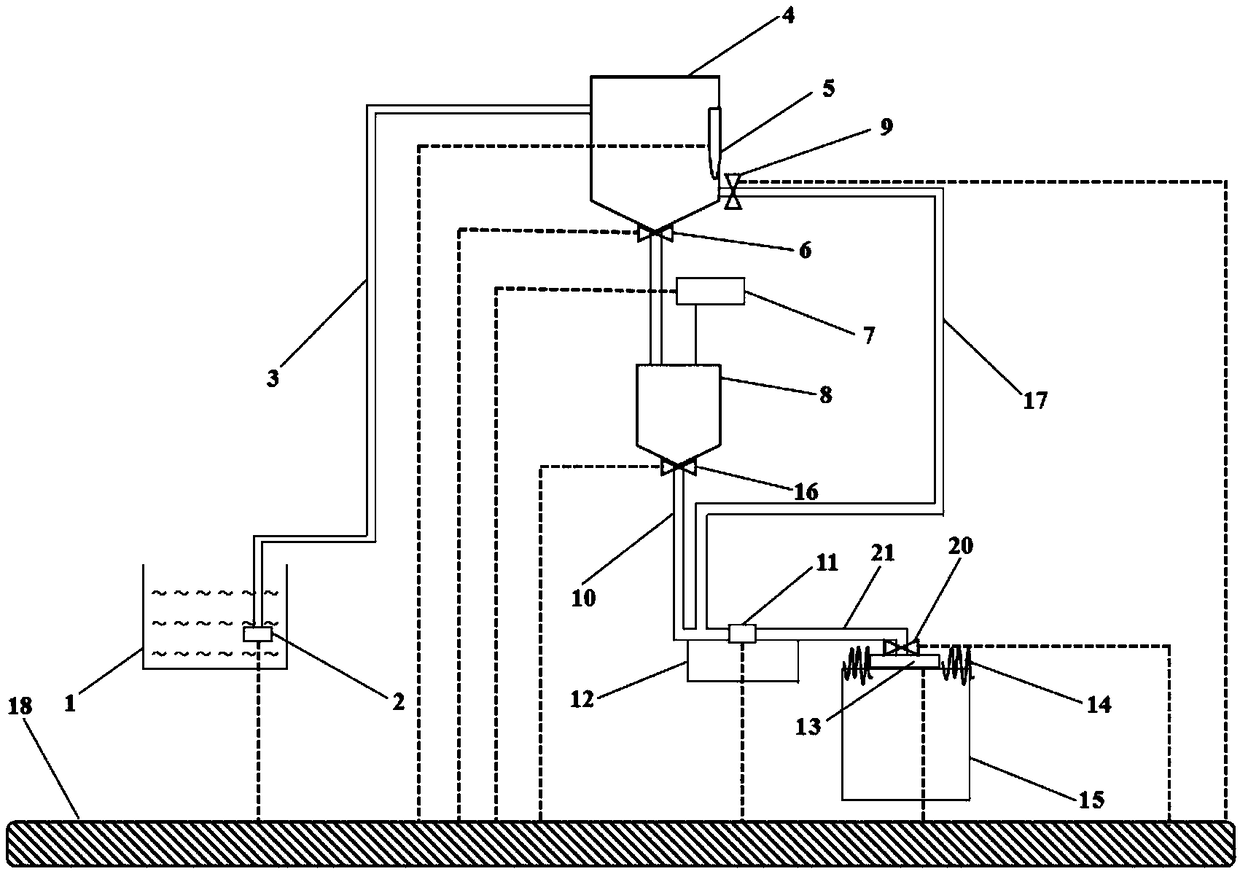

[0045] ginseng figure 1 as shown, figure 1 A structural schematic diagram of an automatic water supply system applied to a concrete mixing plant provided by the present invention, which includes:

[0046] The water storage system includes a pool 1, a water pump 2, and a water storage tank 4. The water pump 2 is arranged at the bottom of the pool 1. The water pump 2 is connected to the inlet of the water storage tank 4 through the water supply pipeline 3. The water storage tank 4 is provided with a liquid level sensor 5 ;

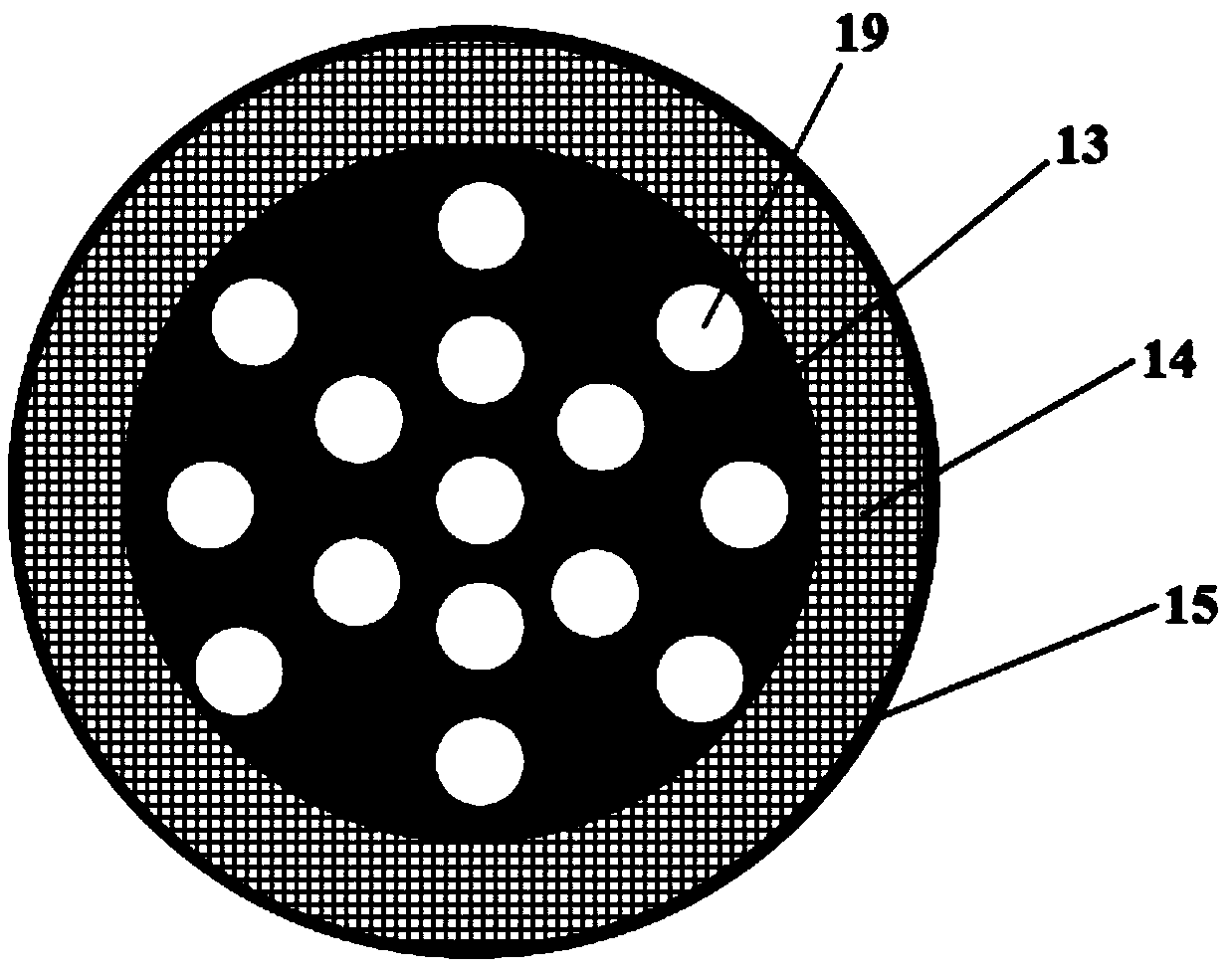

[0047] The metering system includes a weighing sensor 7 and a metering water tank 8. The inlet of the metering water tank 8 is connected to the outlet of the water storage tank 4 through a connecting pipe, and the weighing sensor 7 is connected to the metering water tank 8 for weighing the water volume of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com