Tyre having improved wear and rolling resistance properties

A technology for tires and carcass, applied in the direction of rolling resistance optimization, heavy-duty tires, tire parts, etc., can solve the problems of increased mileage, impact on durability, etc., and achieve the effect of limiting temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

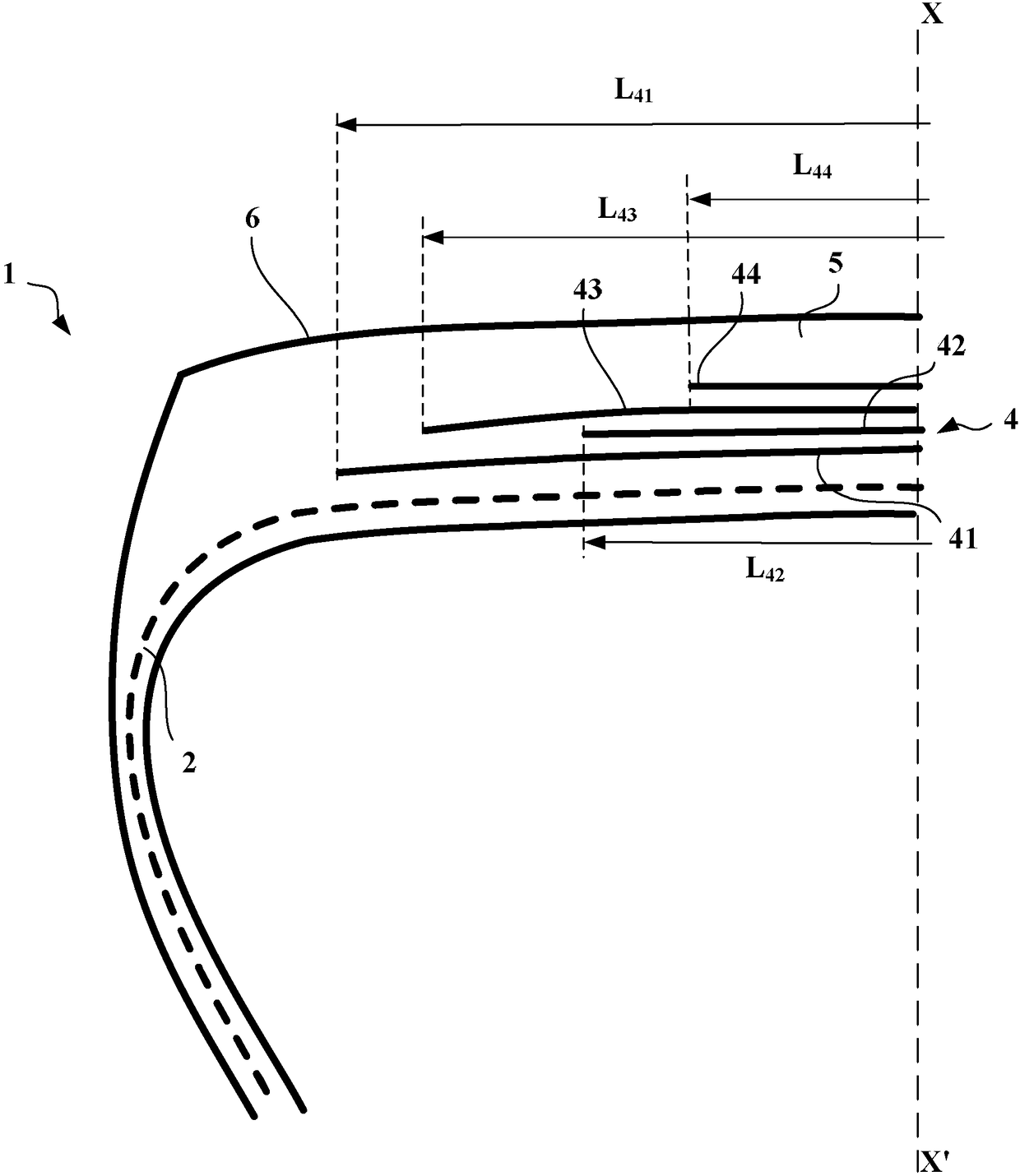

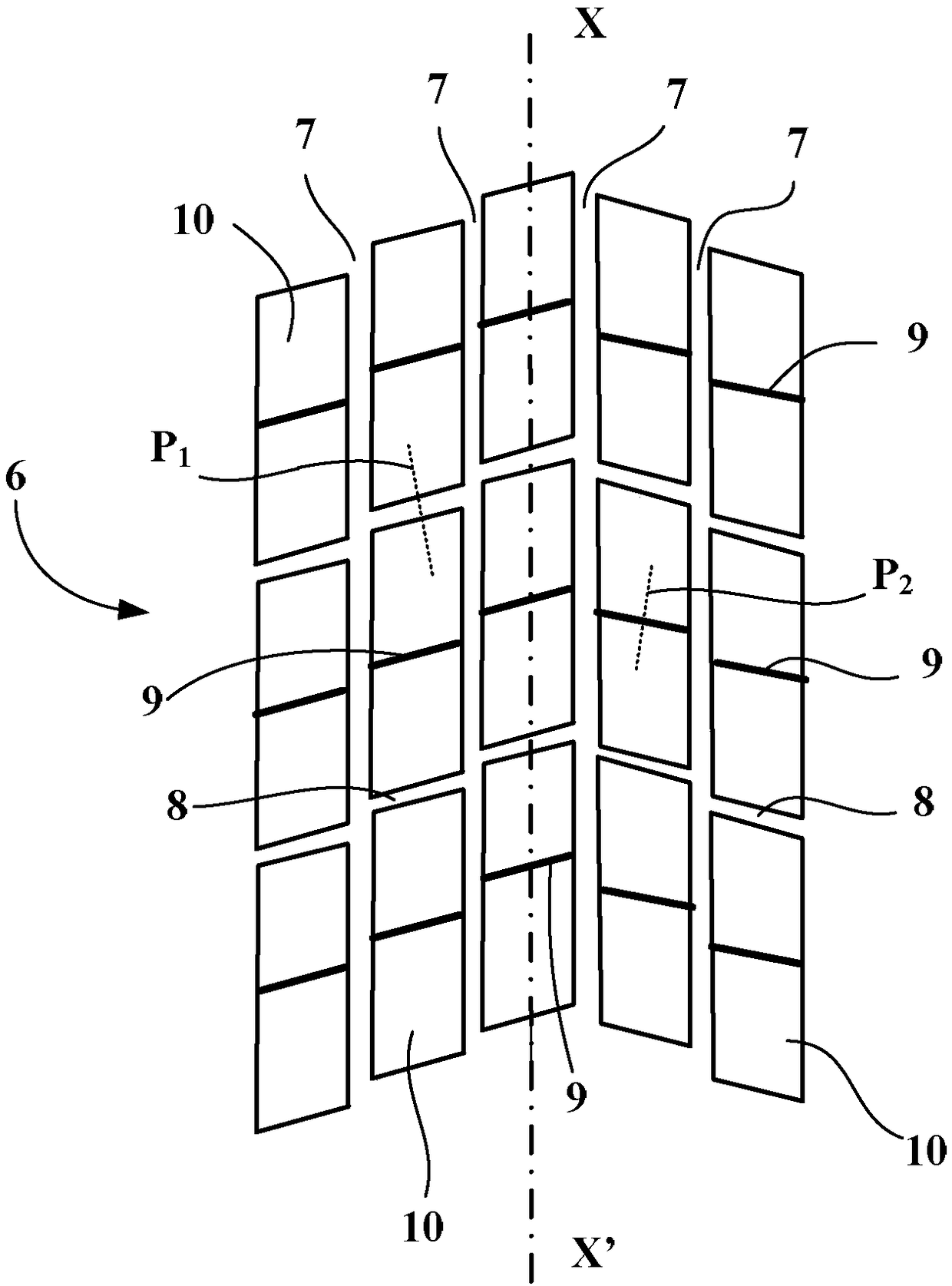

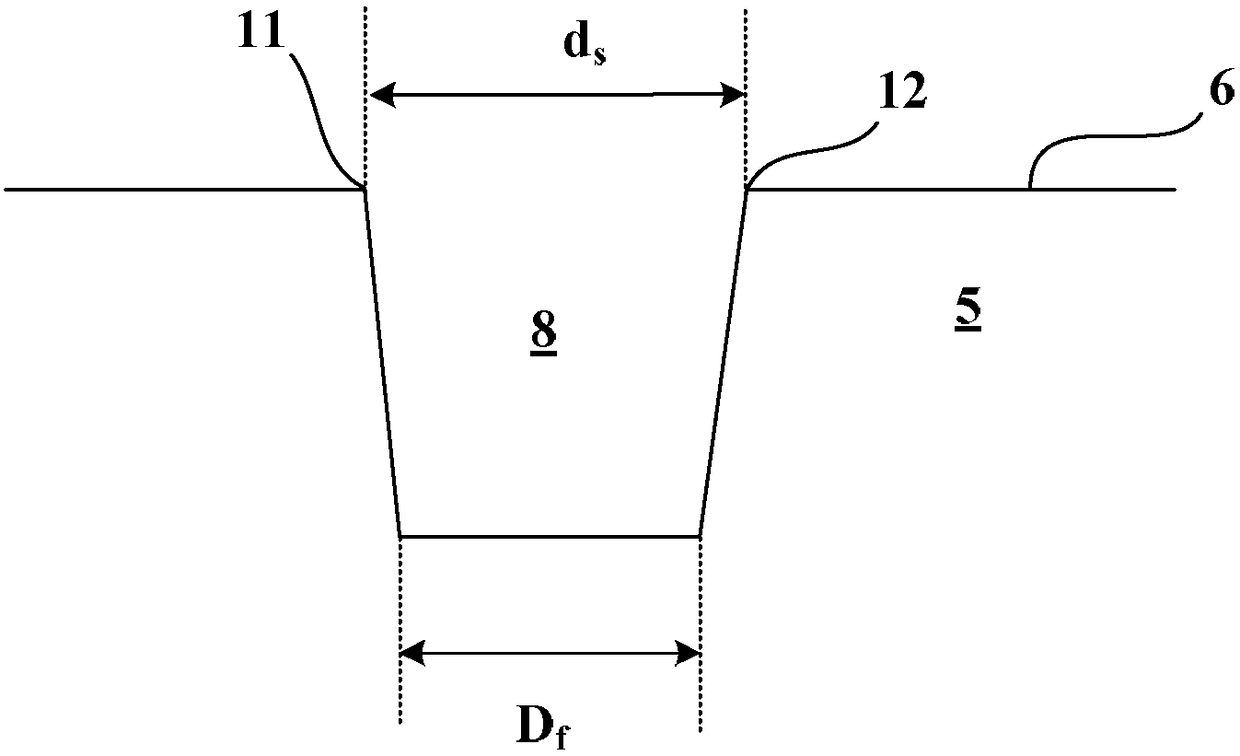

[0117] To simplify understanding, the drawings are not shown to scale. figure 1 Only a half view of the tire is shown, the tire extending symmetrically with respect to the axis XX', which represents the circumferential median plane or equatorial plane of the tire.

[0118] in figure 1 Among them, the tire 1 with a size of 315 / 70R 22.5 has an aspect ratio H / S equal to 0.70, H is the height of the tire 1 on its mounting rim, and S is its maximum axial width. The tire 1 includes a radial carcass reinforcement 2 anchored in two beads (not shown in the figure). The carcass reinforcement is formed of a single layer of metal cords. The carcass reinforcement 2 is wrapped by a crown reinforcement 4, which is formed in the radial direction from the inside to the outside by the following parts:

[0119] -A first working layer 41 formed by unwrapped non-stretchable metal cords 9.28 which are continuous across the entire width of the ply and oriented at an angle of 24°,

[0120] -A layer 42 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com