Tyre with radial ply reinforcement

A technology of reinforcement and reinforcement elements, applied in tire parts, reinforcement layers of pneumatic tires, wheels, etc., can solve problems such as fatigue failure of auxiliary ply cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

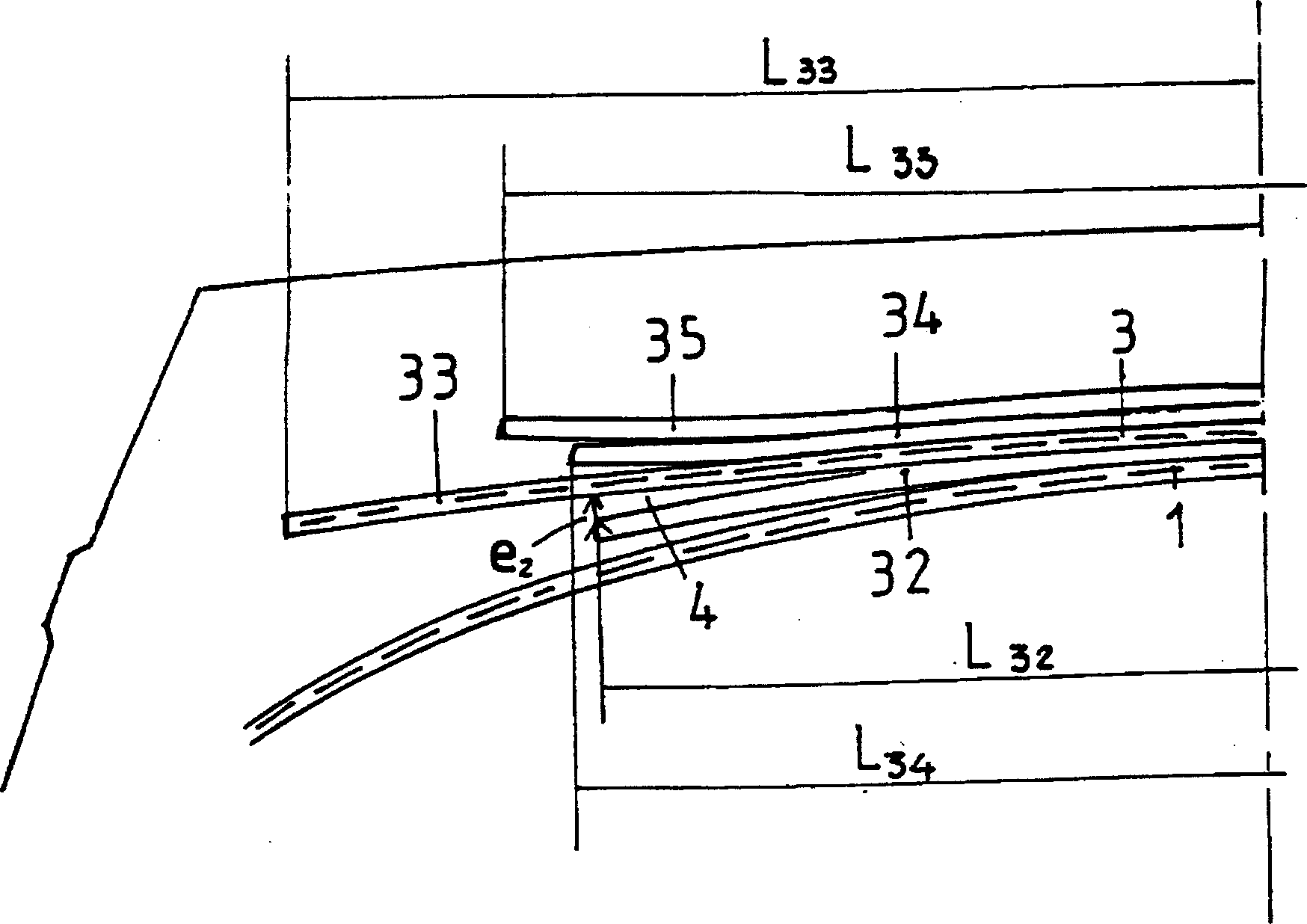

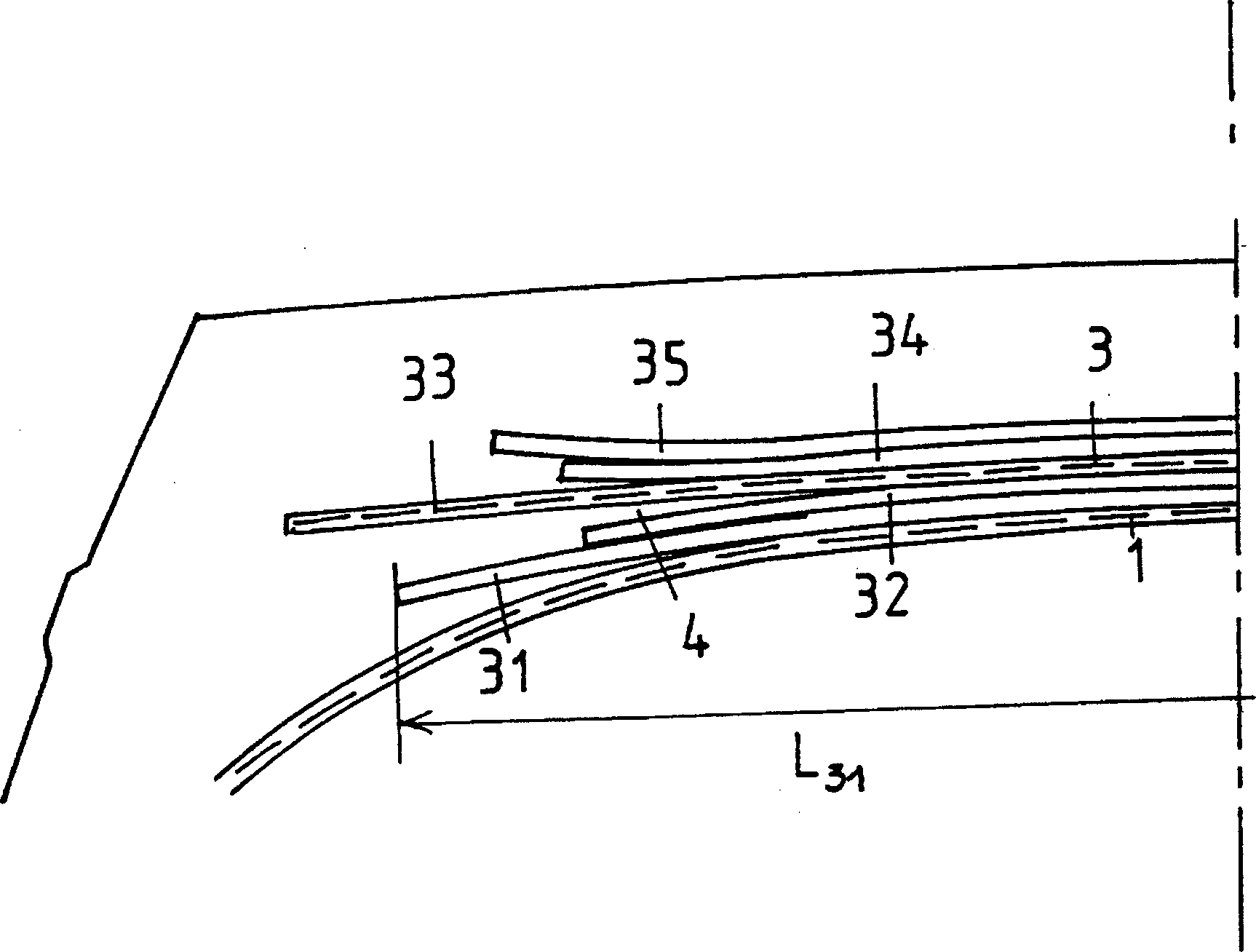

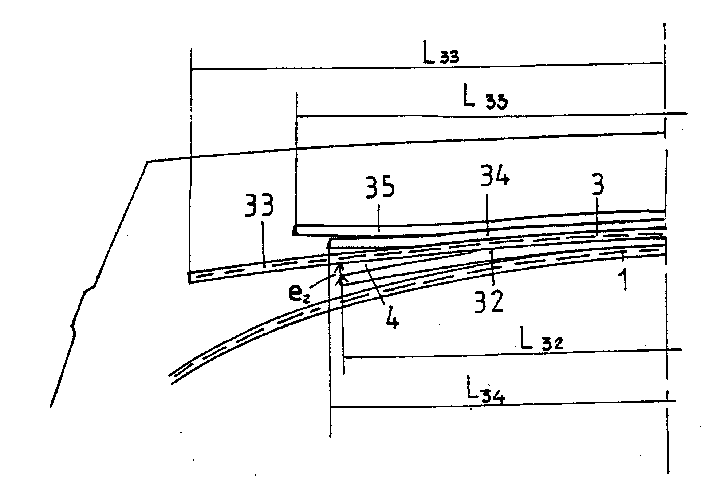

[0016] A tire P of size 385 / 55.R.22.5X has an H / S shape ratio of 0.55, H being the height of the tire P on its mounted rim and S its maximum axial width. Said tire P comprises a radial carcass reinforcement 1 anchored in each bead to at least one bead wire forming an inverted portion and formed by a single ply of metal cables. The carcass reinforcement 1 is surrounded by a crown reinforcement 3 formed radially from the inside to the outside by:

[0017] - a first working crown ply 32 formed by steel inextensible metal cables oriented at an angle α, in the case shown equal to 18°;

[0018] - an auxiliary ply 33 mounted on the first working crown ply 32, formed of inextensible steel metal elements oriented at 90° relative to the circumferential direction, the first working crown ply The axially outer edge of the ply is separated from the auxiliary ply 33 of the radial element by a profiled part 4 of substantially triangular cross-section, between the ply 32 and the ply 33 measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com