Tyre with laced breaker by reinforcement

A technology of reinforcing parts and reinforcing elements, applied to special tires, tire parts, reinforcing layers of pneumatic tires, etc., can solve problems such as limited durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

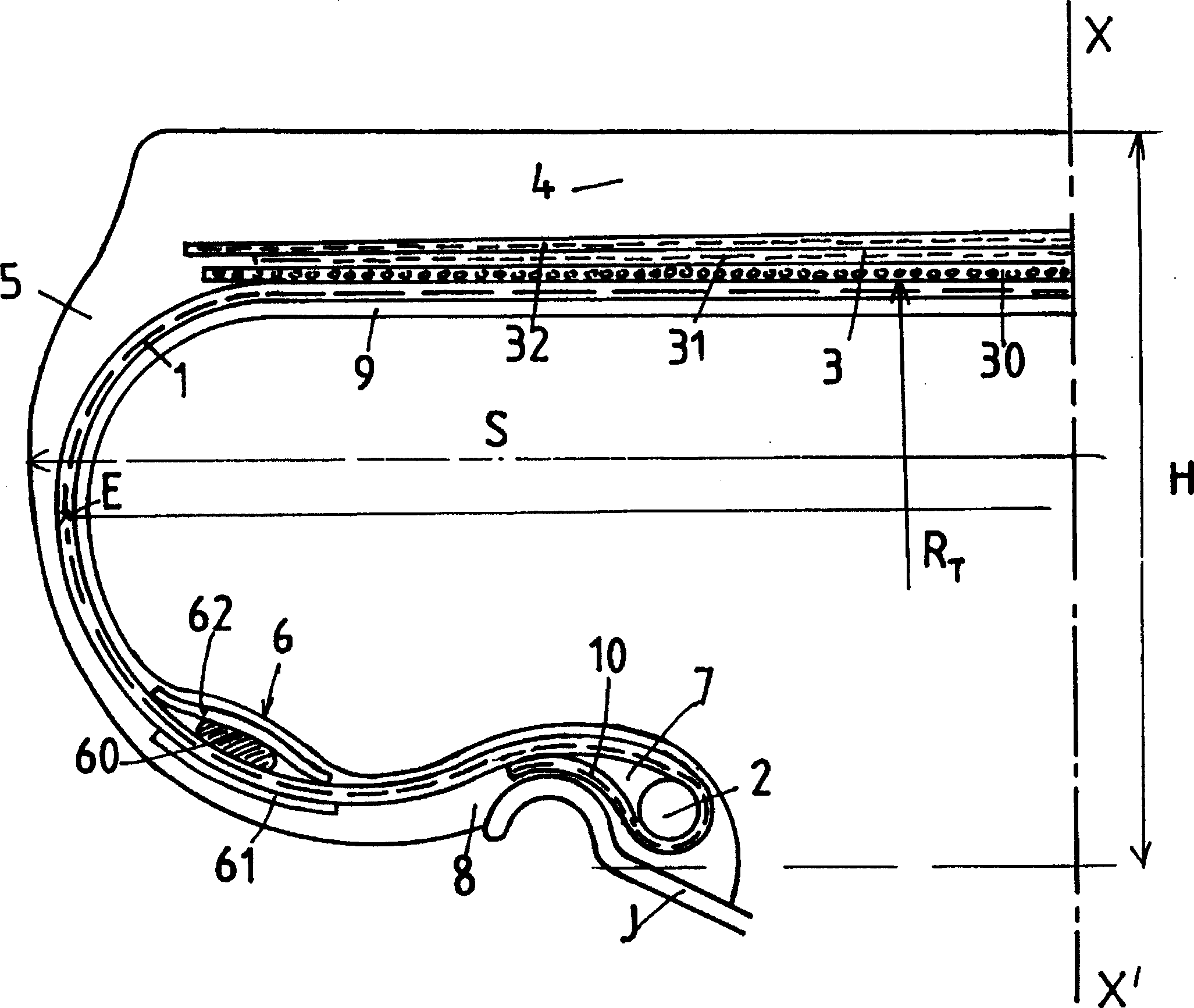

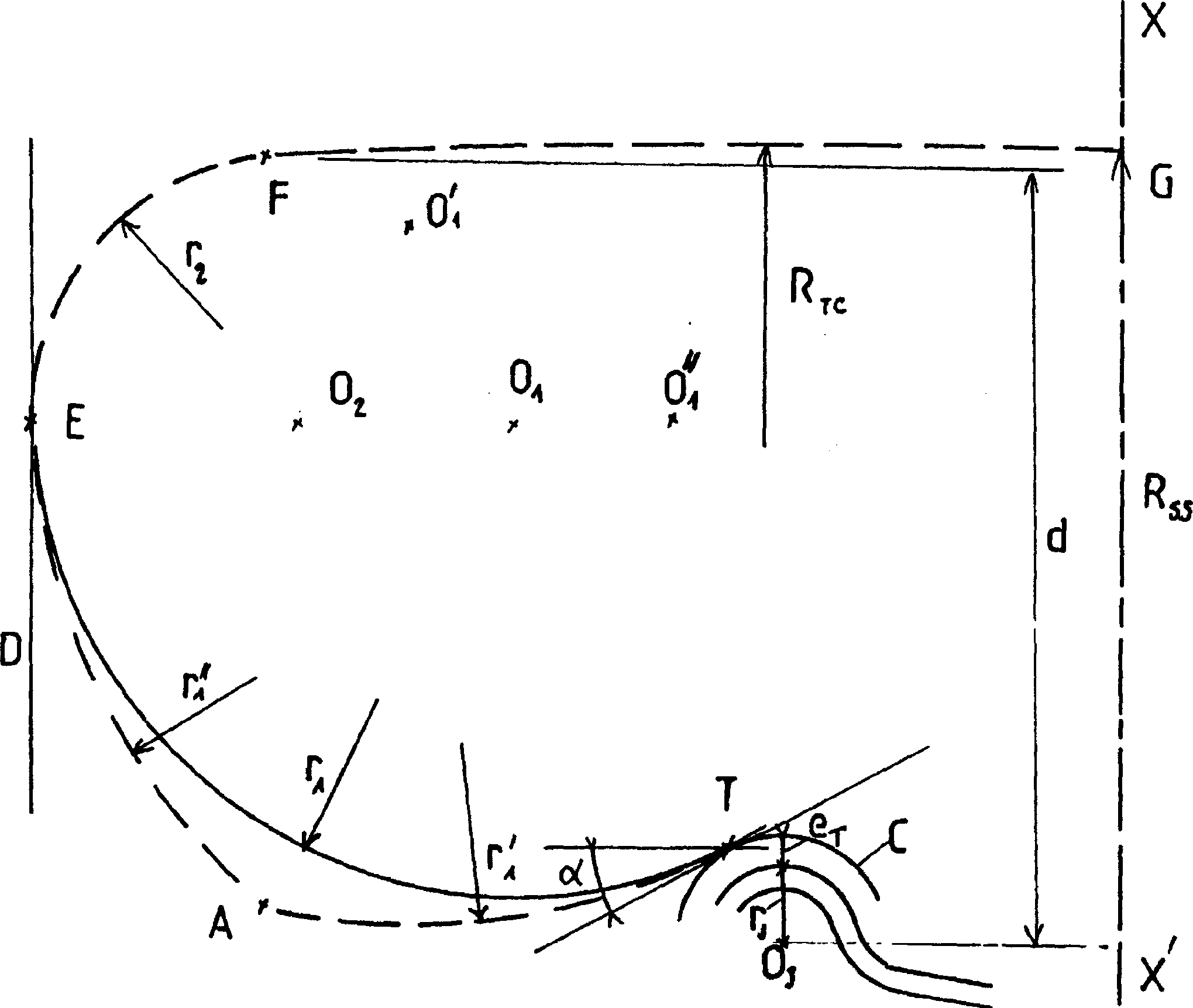

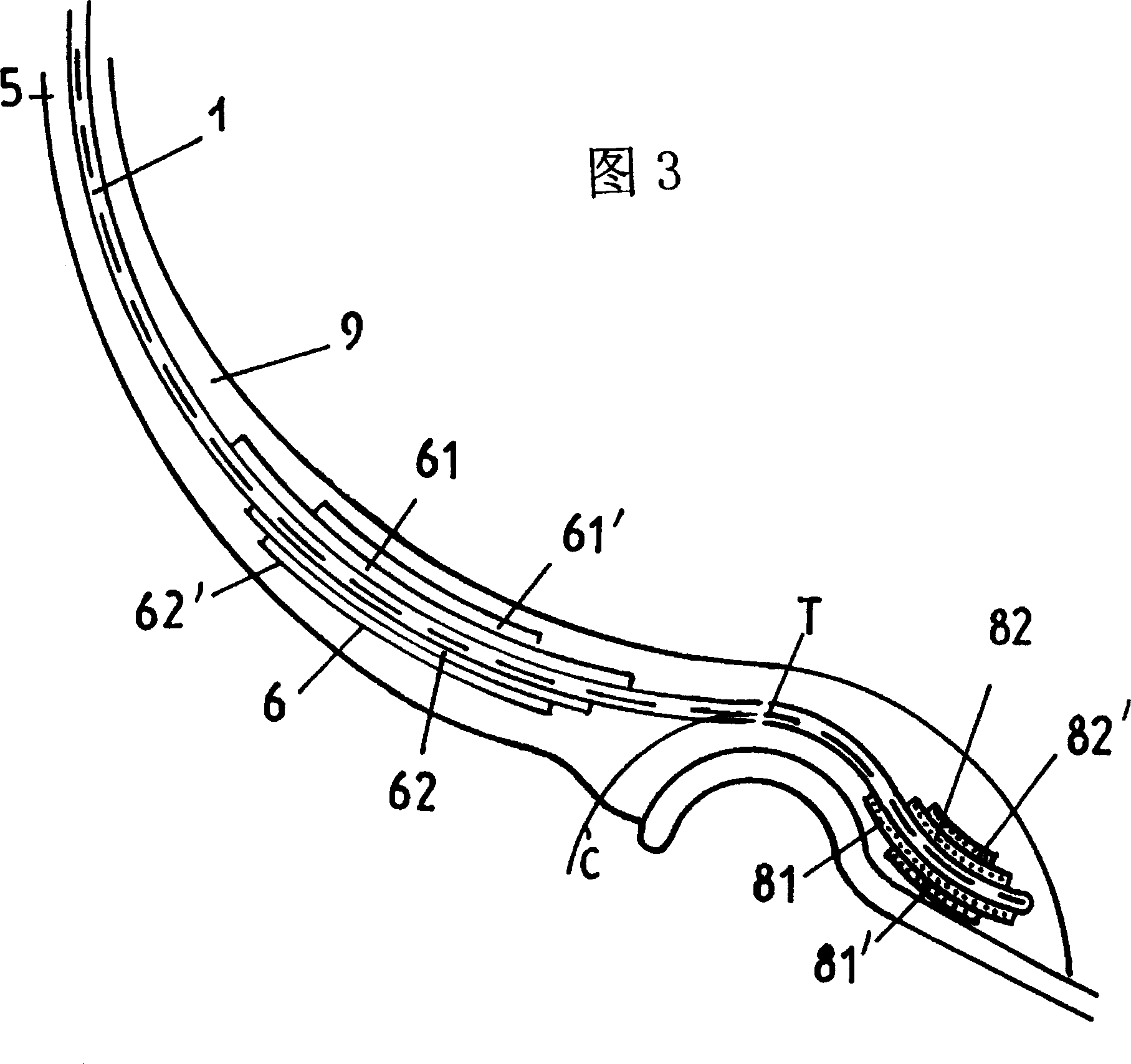

[0031] figure 1 The tire P has a build ratio H / S equal to 0.55 and is mounted on a rim J called a 9×22.5 rim. The carcass reinforcement 1 is formed by a single ply of reinforcing elements being cables made of aramid. Said ply 1 is anchored in each bead B to a braided bead wire 2 and has a portion ( 10 ) folded over itself whose meridian profile surrounds the hook representing the rim J The arc of the circular portion of the edge. Said turned-up portion 10 is separated from the main portion 1 of the carcass ply by a triangular small part 7 . Between the point E of maximum axial width of the carcass ply and the bead wire B is arranged a reinforcing layer 6 which in this case comprises a non-conductive A ply 61 of stretched metal cables, a ply 62 of inextensible metal cables located radially outside the carcass ply 1 and a reinforcing ring 60 between said ply 1 and the ply 62, the reinforcing ring consisting of a Formed from turns of wire, the wire gives the ring an almost pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com