Injection mold for oil pot lid

An injection mold and pot lid technology, which is applied in the field of injection molds for oil pot lids, can solve the problems of high mold processing cost, complex mold structure, low injection efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described now in conjunction with accompanying drawing.

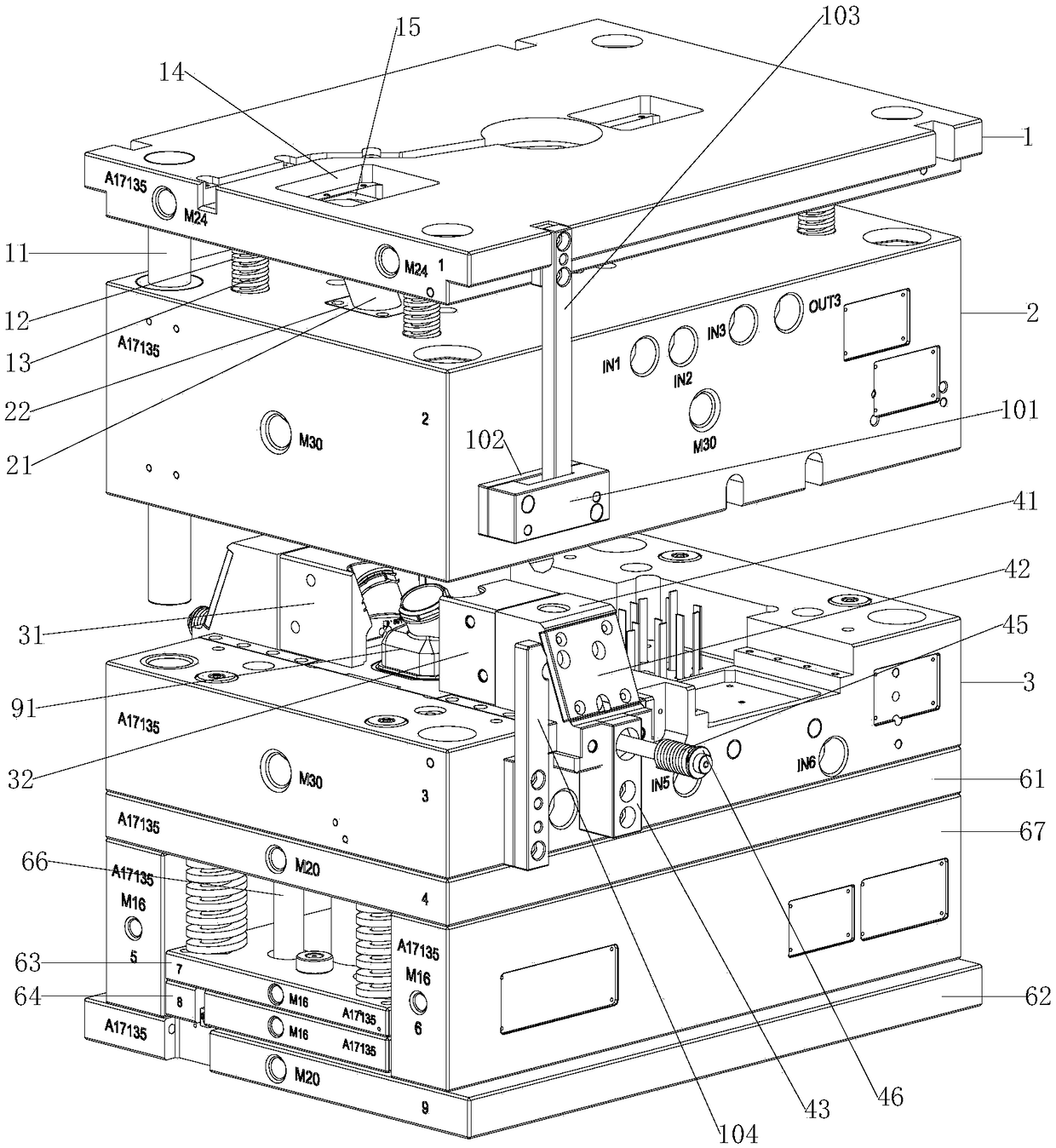

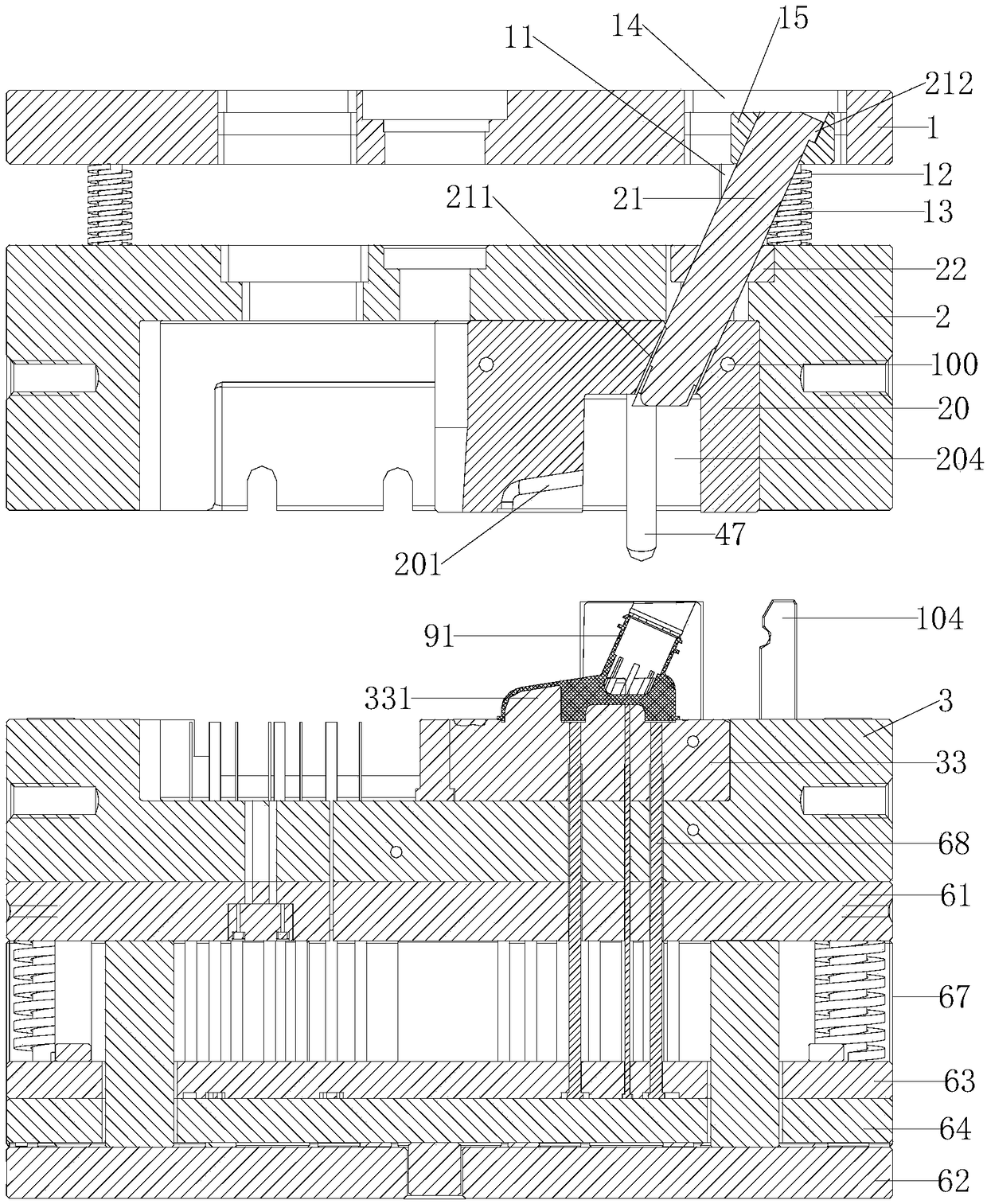

[0047] Such as Figure 1 to Figure 9 Shown, a kind of injection mold of oil pot lid, comprises pot spout core-pulling rod 21, pot lid upper mold core 20, pot lid large side mold core 31, pot lid small side mold core 32 and pot lid lower mold core 33 .

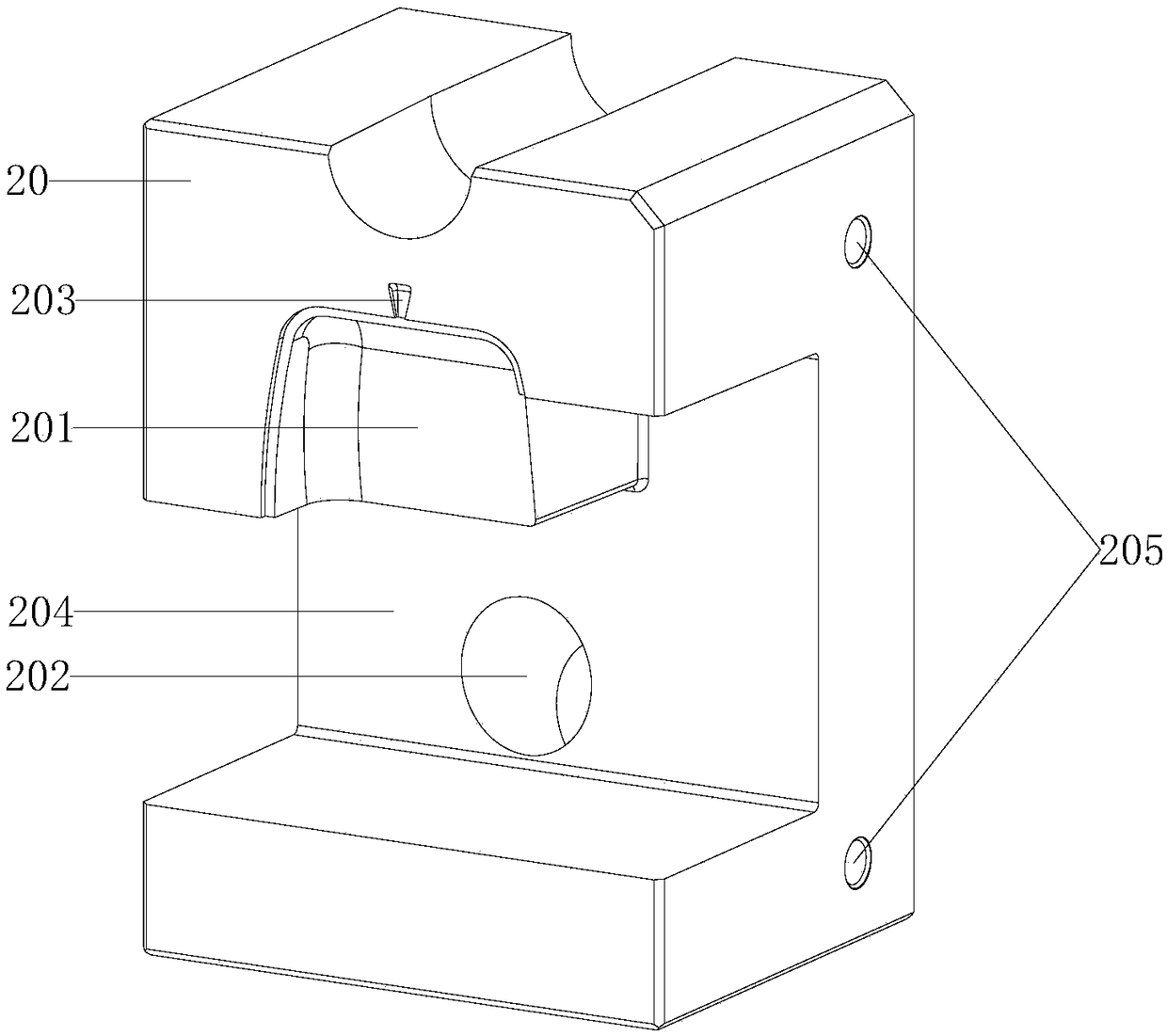

[0048] Such as figure 1 , figure 2 and image 3 As shown, the pot lid upper mold core 20 is fixed on the upper template 2, and the bottom of the pot lid upper mold core 20 is provided with a pot lid cavity A201, a pot lid upper gate 203 and a pot lid side mold core groove 204. The gate 203 communicates with the pot lid cavity A201, the top of the mold core 20 on the pot lid is provided with a spout core-pulling inclined hole 202, and the spout core-pulling inclined hole 202 communicates with the pot lid side mold core groove 204.

[0049] Such as Figure 4 and Figure 5 As shown, the bottom of the large side mold core...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap