Hot-rolled enamel steel plate for subway decoration, and manufacturing method thereof

A manufacturing method and enamel technology, applied in the field of metallurgical technology, can solve problems such as increasing cost, affecting appearance, and impact, and achieve the effect of stabilizing production and ensuring the adhesion of enamel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

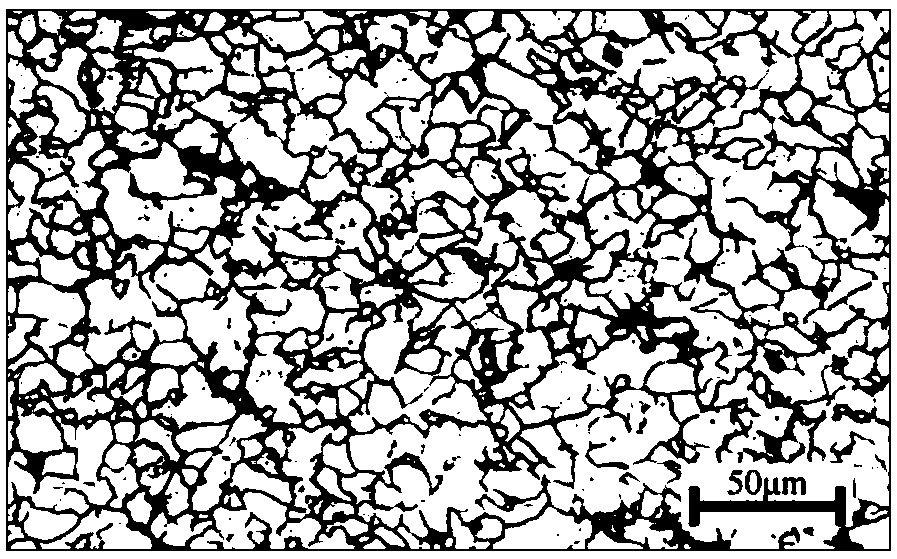

Image

Examples

Embodiment Construction

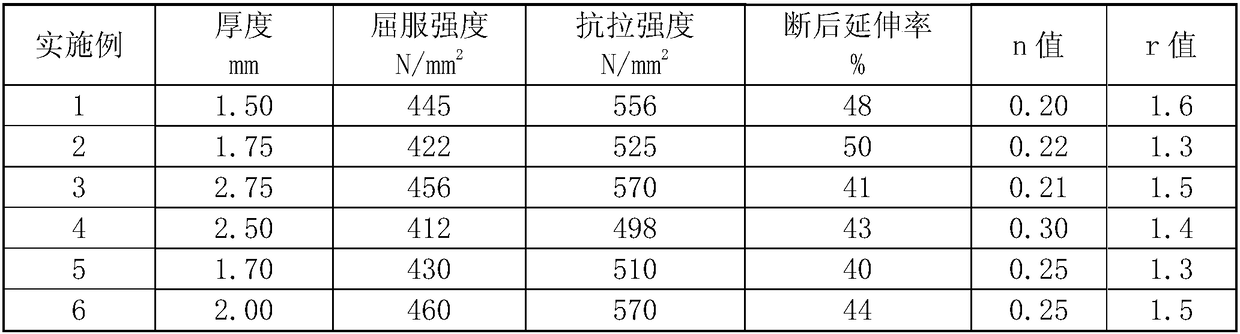

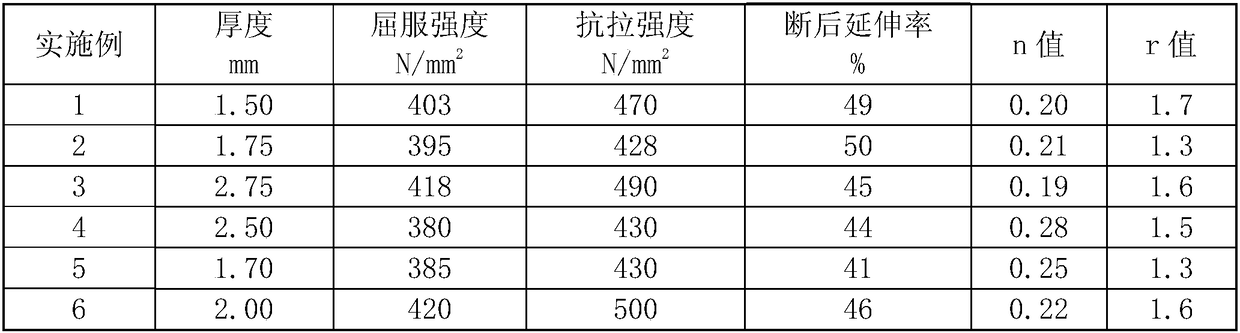

[0031] See Table 1 for the chemical composition wt% of the hot-rolled enamelled steel sheets of the examples; see Table 2 for the rolling process parameters of the examples; see Table 3 for the physical properties of the examples; and see Table 4 for the properties of the hot-rolled enamelled steel sheets of the examples.

[0032] Table 1 embodiment hot-rolled enamel steel sheet chemical composition wt%

[0033] Example

C

Si

mn

P

S

Ti

Cr

ALs

1

0.053

0.12

0.66

0.011

0.012

0.058

0.14

0.034

2

0.068

0.16

0.88

0.012

0.008

0.089

0.20

0.050

3

0.079

0.10

0.94

0.011

0.006

0.068

0.12

0.045

4

0.050

0.18

0.90

0.009

0.015

0.098

0.16

0.028

5

0.088

0.20

0.92

0.010

0.013

0.078

0.19

0.035

6

0.065

0.11

0.95

0.006

0.010

0.089

0.13

0.015

[0034] Table 2 embodiment rolling proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com