Manufacturing method of sheet metal shell with circular arc fluted edge meeting spherical apex

A technology of arc and shell, applied in the field of factory sheet metal processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

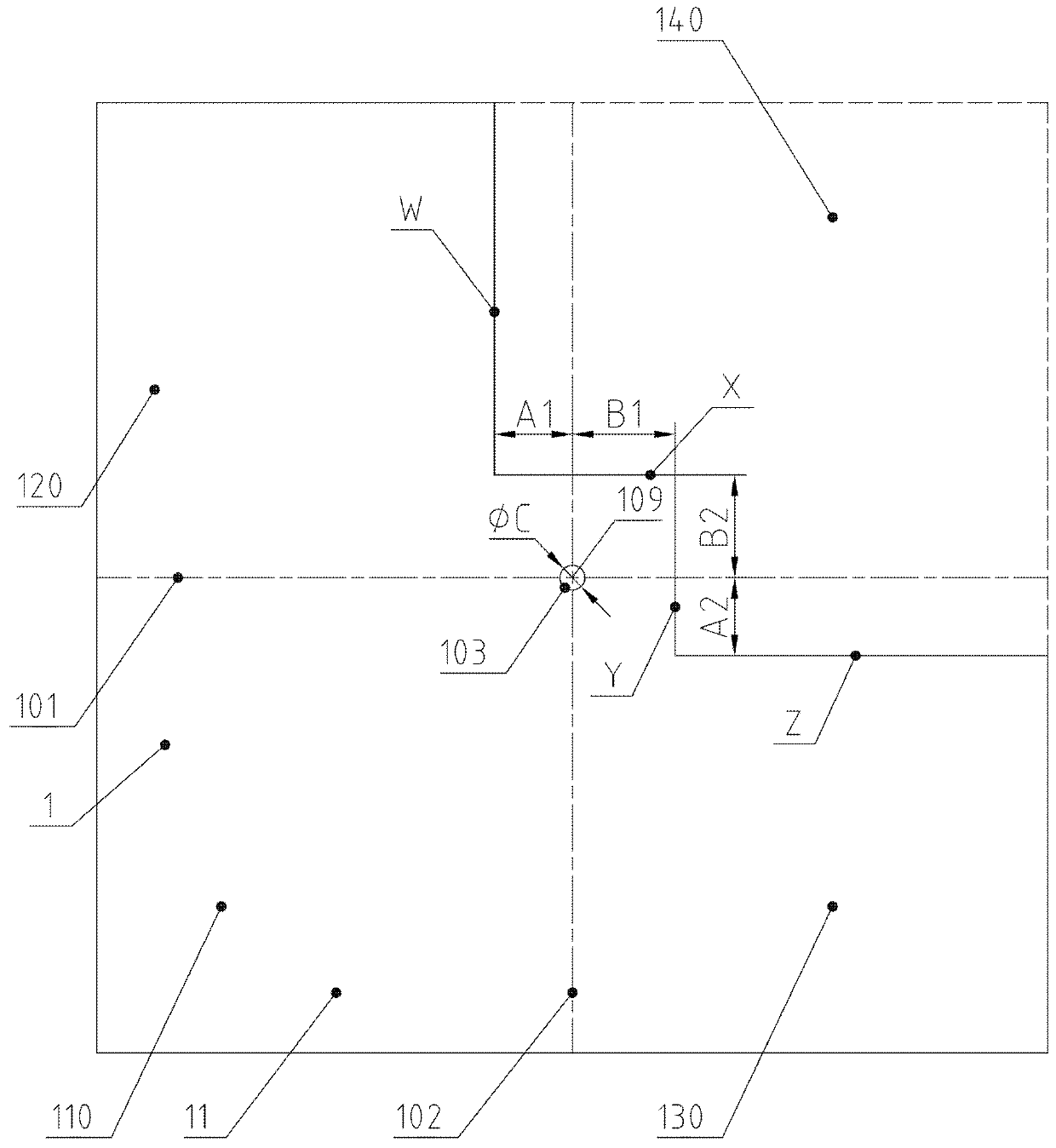

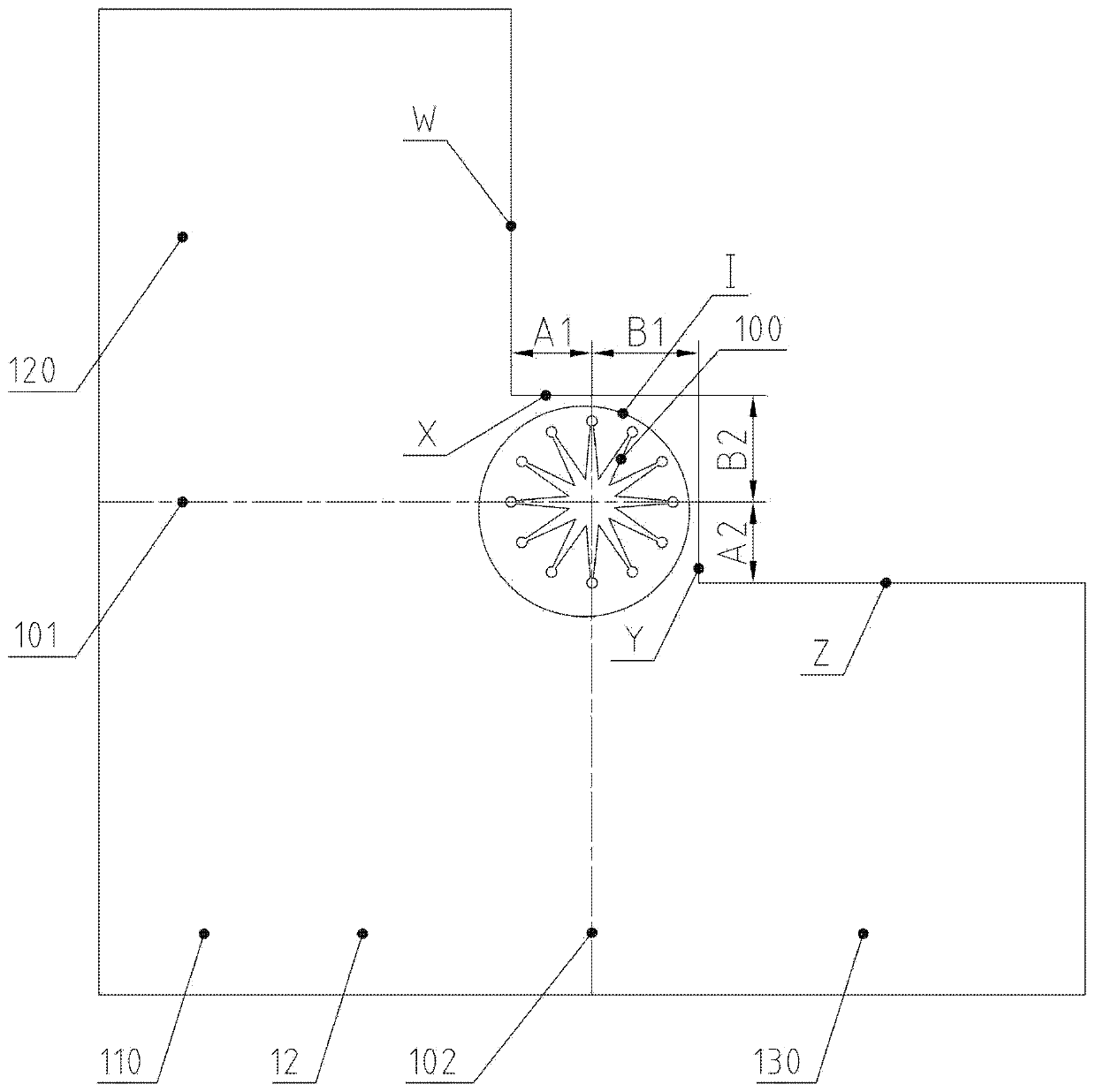

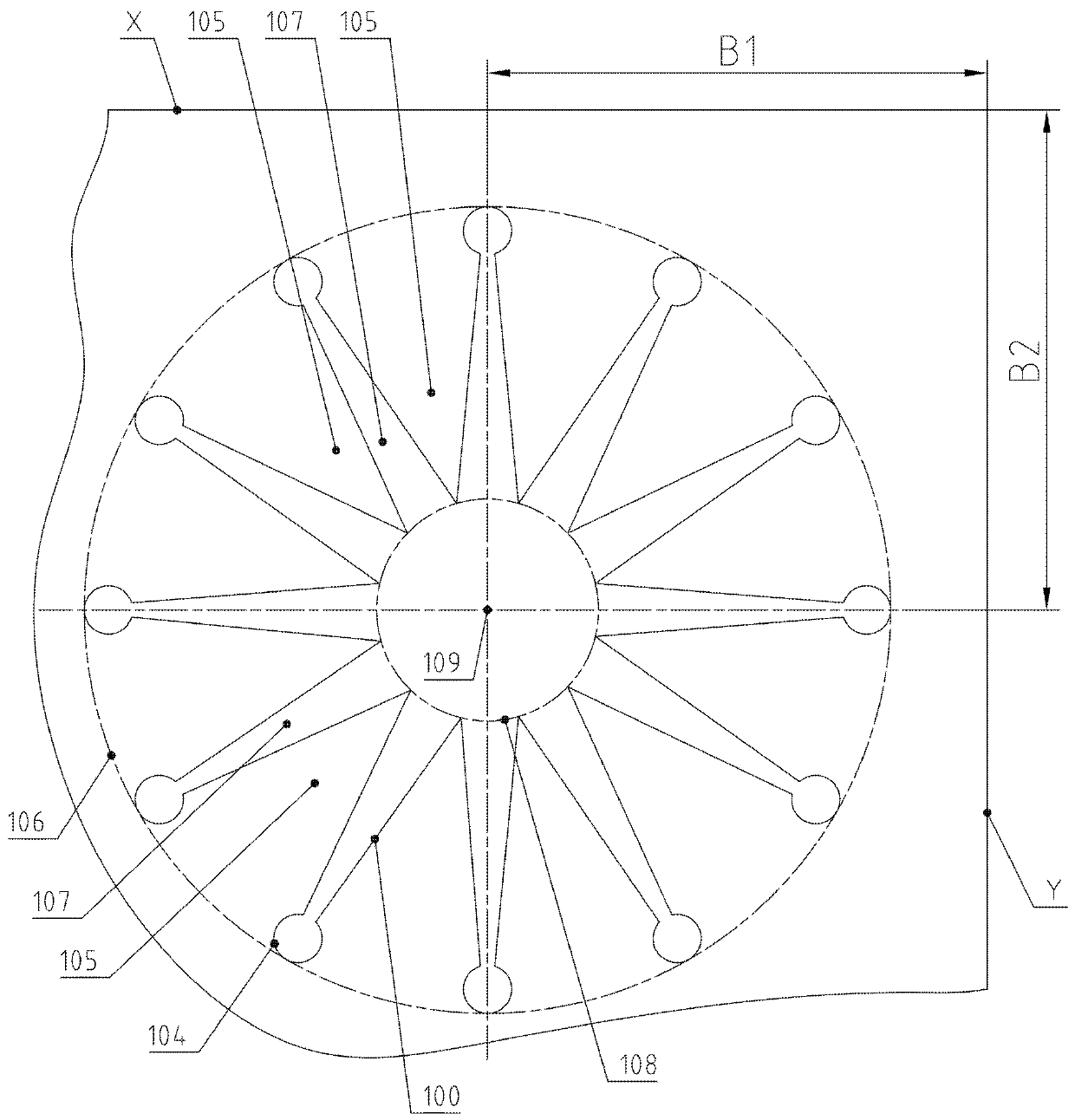

[0055] Example: see Figure 1 to Figure 14 .

[0056] A method for manufacturing a vertex of a circular-arc corrugated edge meeting a sphere of a sheet metal shell, taking as an example the processing of three circular-arc corrugated edges meeting the vertex of a sphere with a thickness T of 1.5 millimeters and a radius of arc corrugated edges of R = 20 mm instructions, including the following steps:

[0057] 1) On the cut rectangular main board 1 with a thickness of T = 1.5 mm, determine and draw the vertical bending center line 1 101 and bending center line 2 102 according to the size of the finished part, using a stylus. The point where the bending center line 1 101 and the bending center line 2 102 intersect is the positioning point 109, and the bending center line 1 101 and the bending center line 2 102 divide the blank of the main board 1 into four parts, which are respectively the fixing part 110 and the bending part 120 1. The second bending part 130 and the cut-off ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com