Pipe joint

A technology for pipe joints and joint pipes, which is applied in the field of pipe joints, can solve the problems of easy displacement of elastic snap rings, increased production costs, and poor sealing effects, and achieves the effects of simple structure, reduced assembly parts, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

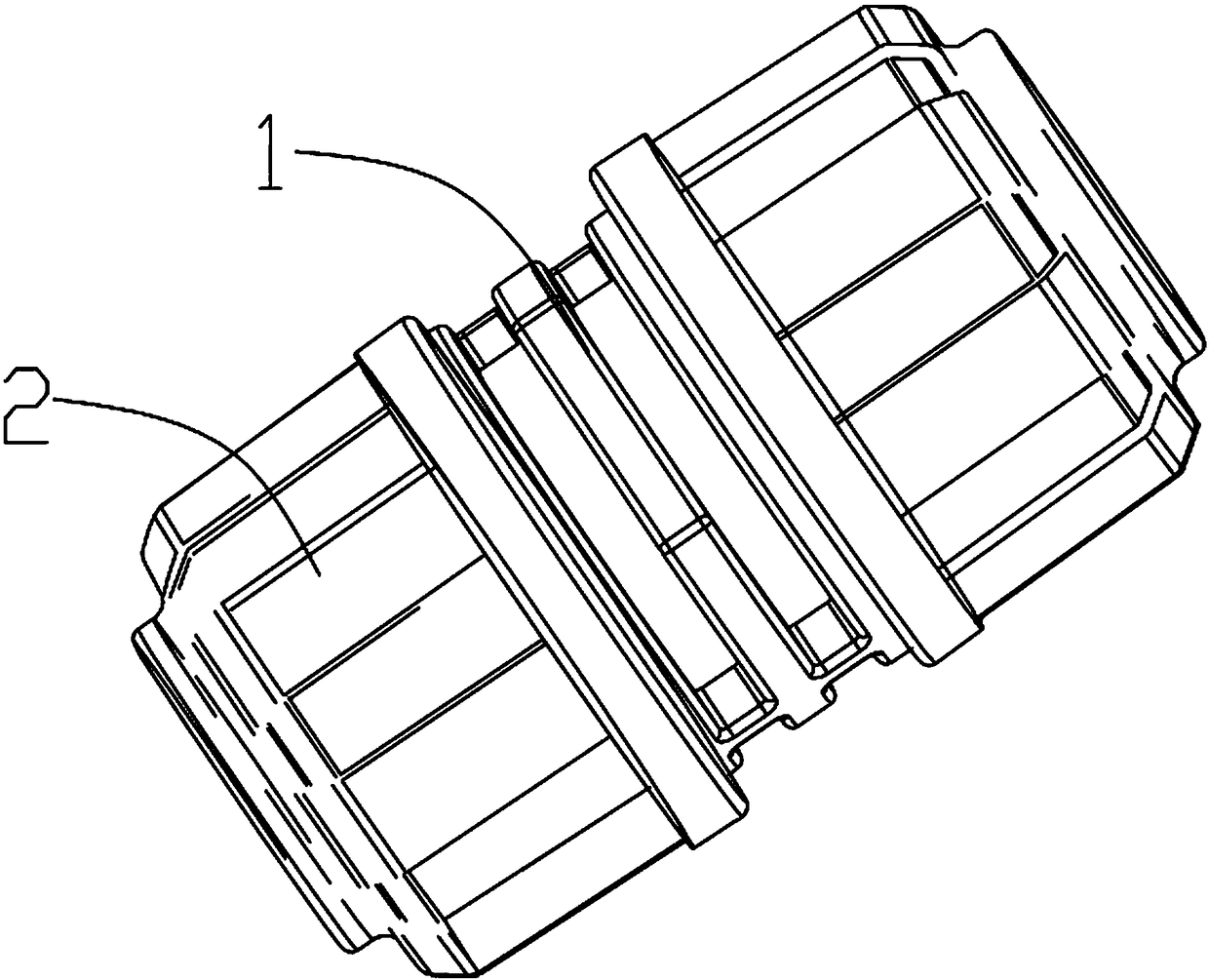

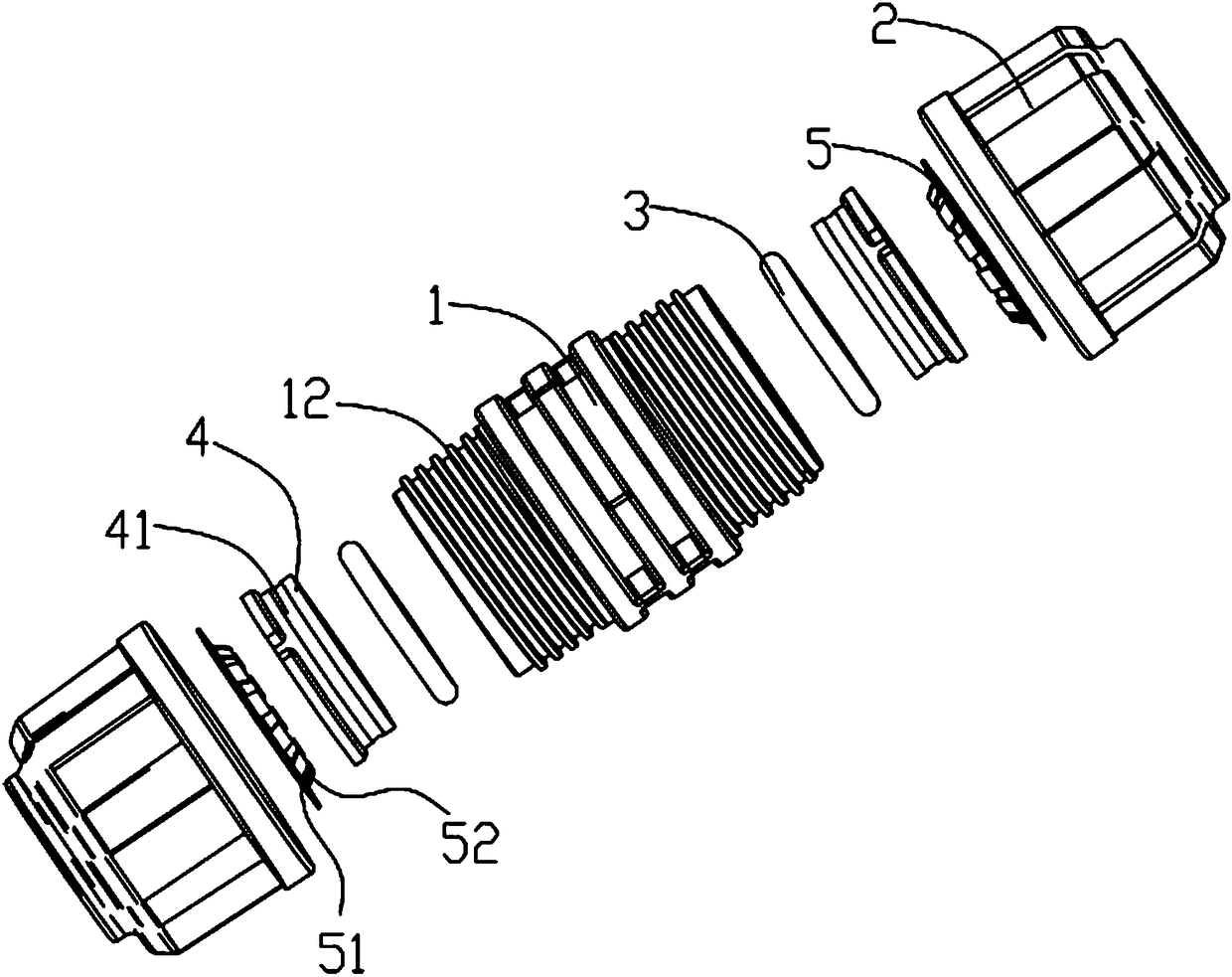

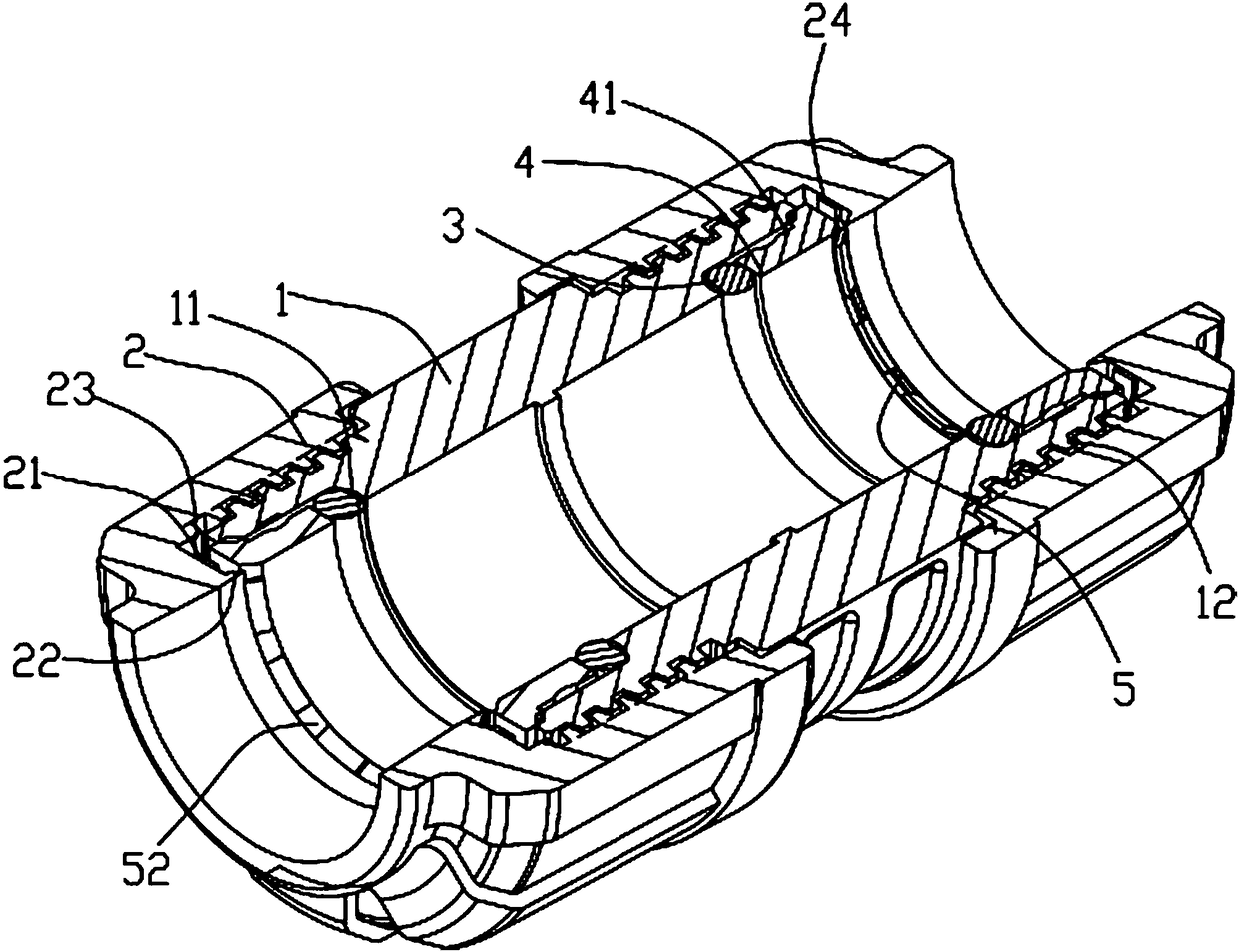

[0013] see attached Figure 1-3 , the present invention includes a joint pipe 1 and a gland 2 sleeved on both ends of the joint pipe 1, the gland 2 and the joint pipe 1 are detachably connected by threads, and the end of the joint pipe 1 is provided with a snap ring seat 4 , one end of the snap ring seat 4 extends into the inside of the joint pipe 1 and is in contact with the sealing ring 3 arranged in the joint pipe 1. The other end of the snap ring seat 4 is provided with an elastic snap ring 5, which is elastic The snap ring 5 includes a ring body 51 and claw teeth 52 . The claw teeth 52 are flanged toward the snap ring seat 4 , and a bevel ring is provided at the opening of the snap ring seat 4 , and the claw teeth 52 abut against the bevel ring. Above, the port of the end head of the joint pipe 1 is a conical port, the other en...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap