Distribution flow controller

A technology of flow controller and batcher, which is applied in the flow control of auxiliary non-electric power, etc., can solve the problem that the mixing uniformity of ingredients is difficult to control, and achieve the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

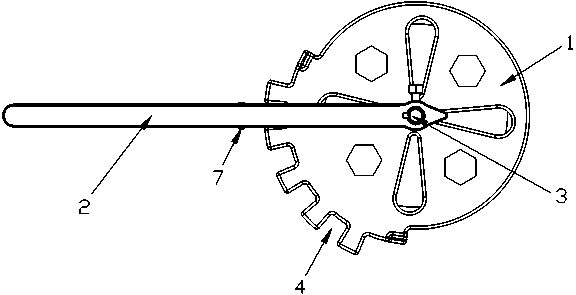

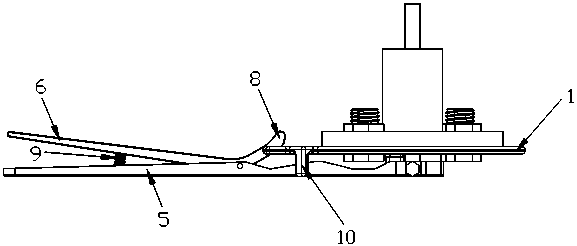

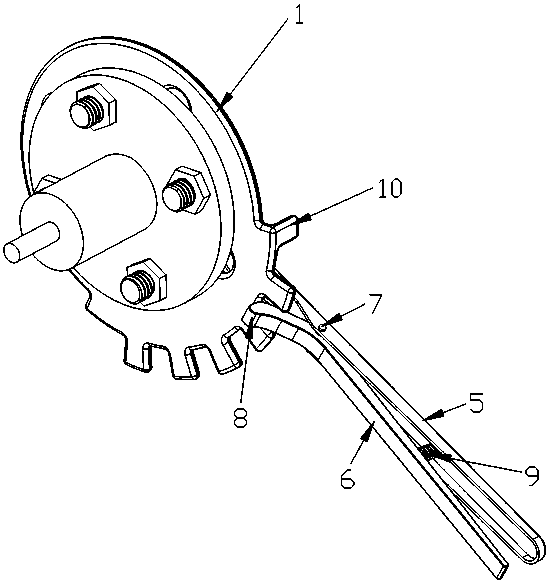

[0021] Such as Figure 1 to Figure 6 The batching flow controller shown includes a fixed disk 1 and an operating handle 2. The fixed disk 1 is used for detachably installing the housing at the outlet of the batcher and the fixed disk 1 is rotated to set There is a rotating shaft 3, specifically, an axial through hole (not shown in the figure) passing through both sides of the fixed disk 1 is opened, and the rotating shaft 3 passes through a bearing arranged in the axial through hole (in the figure not shown) is rotatably connected with the fixed disk 1, and one end of the rotating shaft 3 is used to extend into the discharge port of the batcher and is provided with a valve plate (not shown in the figure) for adjusting the opening size of the discharge port of the batcher The other end of the rotating shaft 3 passes through the fixed disk 1 and is connected to the operating handle 2, and the edge of the fixed disk 1 is uniformly provided with a plurality of slots 4, the present...

Embodiment 2

[0030] In this embodiment, the structure to realize the connection between the rotating shaft 3 and the operating handle 2 is that the handle body 5 is provided with an installation through hole 14 and a threaded through hole 15 perpendicular to the installation through hole 14. The threaded through hole 15 is provided with a fixing bolt 16 threadedly engaged with the threaded through hole 15 , and the end of the fixing bolt 16 abuts against the pin shaft 7 . The rest of the structure of this embodiment is the same as that of Embodiment 1. For details, reference may be made to Embodiment 1, which will not be repeated here.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap