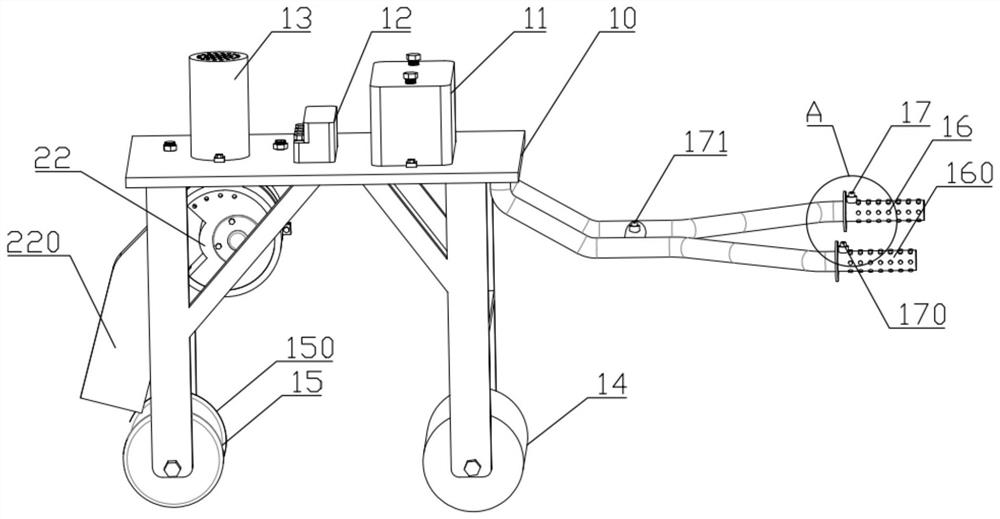

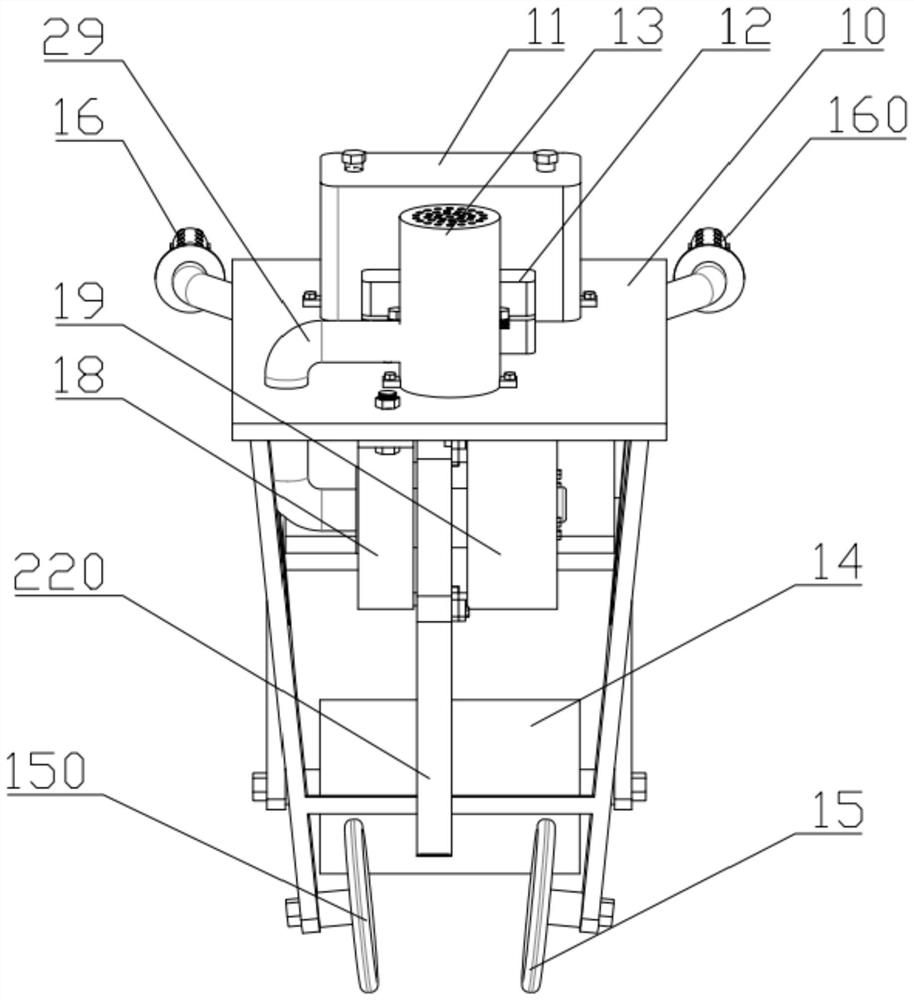

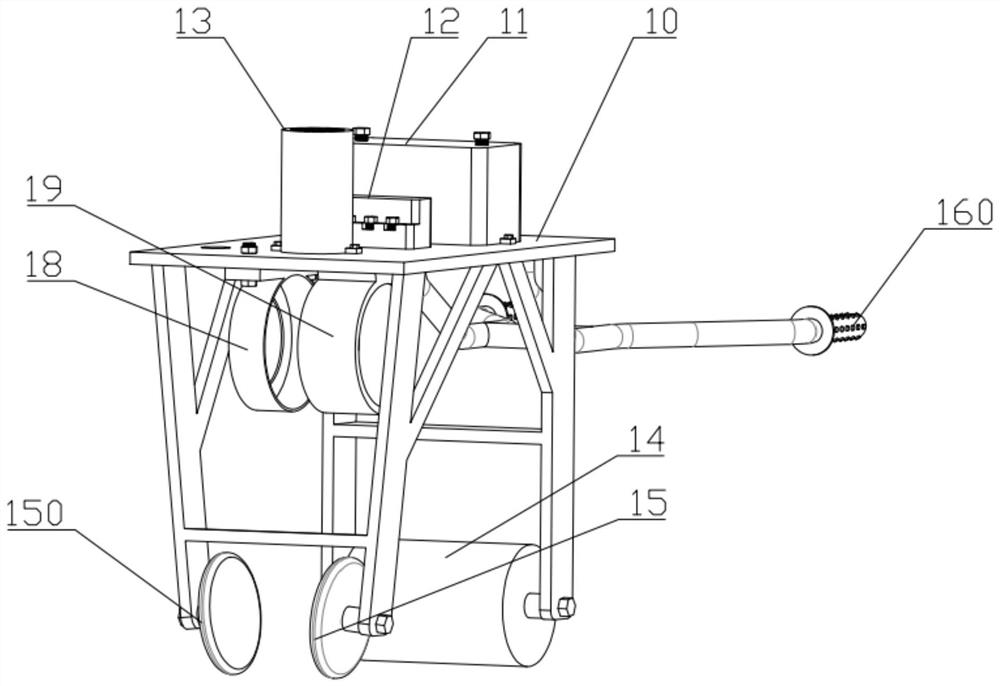

Precision seeding device for particle seeds

A precision seeding and seeding technology, which is applied in the field of precision seeding devices for particulate seeds, can solve the problems of unadjustable seed distance, missed seeding, low seeding efficiency, etc., and achieve the effect of improving seeding efficiency and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Open the seeding cover 210, put the seeds into the seed storage tank 21, close the seeding cover 210, open the first resistance switch 17, the fan 13 rotates, and form a negative pressure on the sowing assembly 20 through the suction pipe 29, and the seeding assembly 20 The gas enters the suction chamber 27 from the air vent 271 on the suction chamber 27, and the seeds are adsorbed on the adsorption hole 230 on the turntable 23, and then the gas enters the suction chamber from the adsorption hole 230 from the first suction port 270, And enter the vent 271 from the second suction port 272, drive the fan 25 to drive the rotating disk 23 to rotate, when the seeds in the adsorption hole 230 on the rotating disk 23 forward to the discharge pipe 220 of the seed part 22, the negative pressure disappears, The seeds fall into the discharge pipe 220, drop from the discharge pipe 220 to the soil between the first pressing wheel 15 and the second pressing wheel 150, open the third r...

Embodiment 2

[0043] Compared with Embodiment 1, in Embodiment 2, the fan 25 is replaced by a motor 26, and a second resistance switch 170 is set on the second direction bar 16, and a wire hole 273 is set on the suction chamber 27. By opening the second resistance switch 170 can adjust the size of the electric current through the motor 26, control the rotating speed of the motor 26 and the turntable 23, thereby controlling the output speed of the seeds.

[0044] In the present invention, by arranging the adsorption hole 230 as a semicircle, the contact area between the turntable 23 and the seeds can be increased during sowing, so that seeds of different sizes can cling to the turntable 23 under the action of negative pressure, preventing the seeds from Drop during rotation to achieve precise seeding; by setting the pressing wheel 15 and the electric travel wheel 16 on the frame 10, the driving speed of the seeder can be artificially changed according to the output speed of the seed, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com