Multifunctional electric cutting angle grinder

A cutting angle, multi-functional technology, applied in the field of multi-functional electric cutting angle grinder, can solve the problems such as poor cutting effect of stone and polished metal surface, poor cutting effect of wood and metal plate, etc., and achieve good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

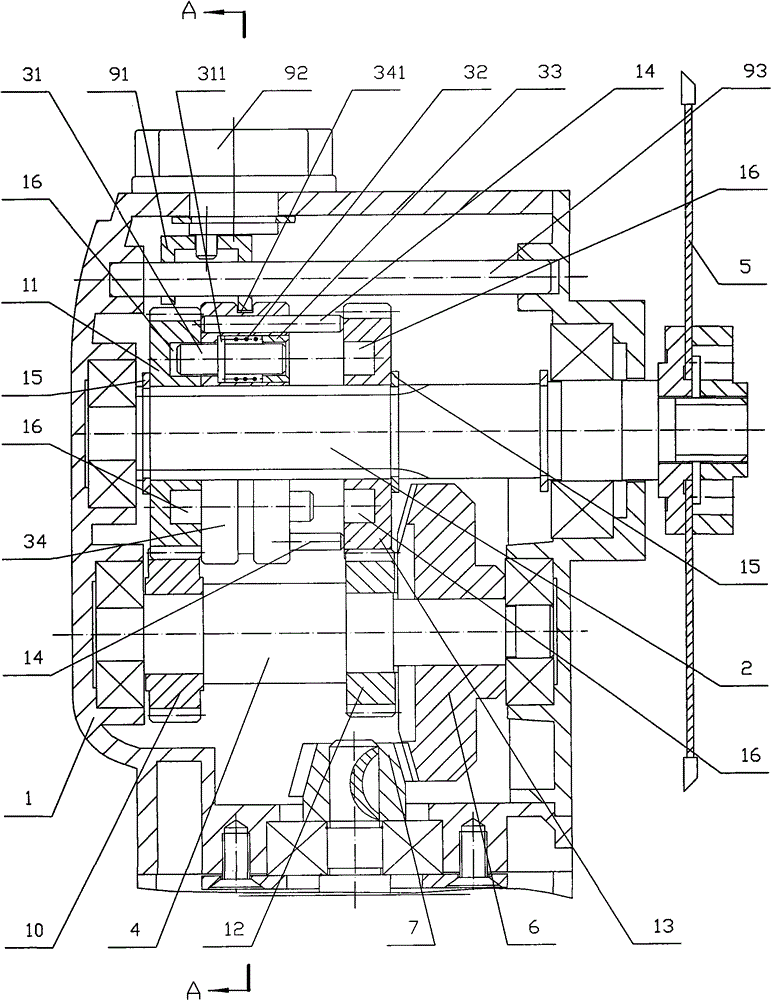

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

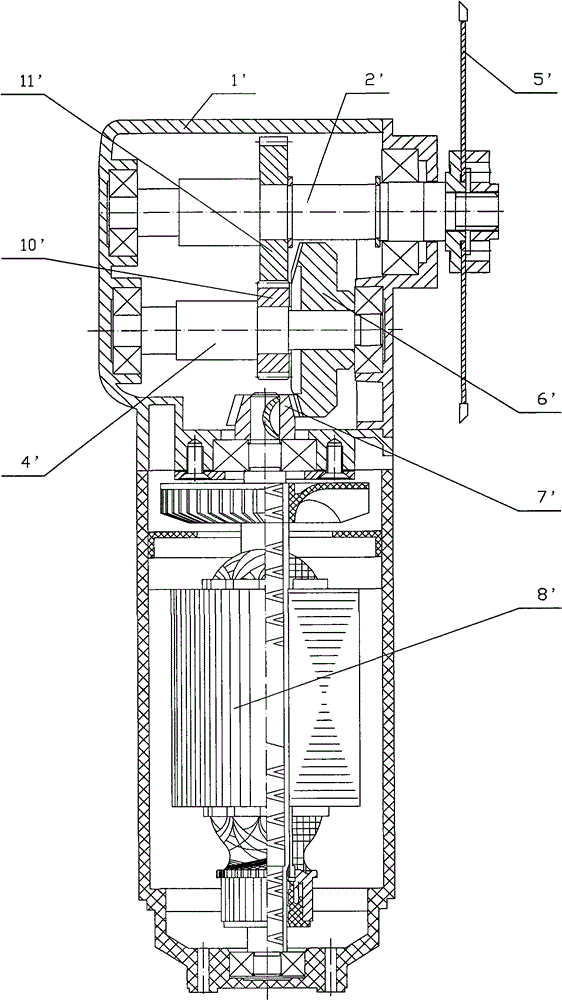

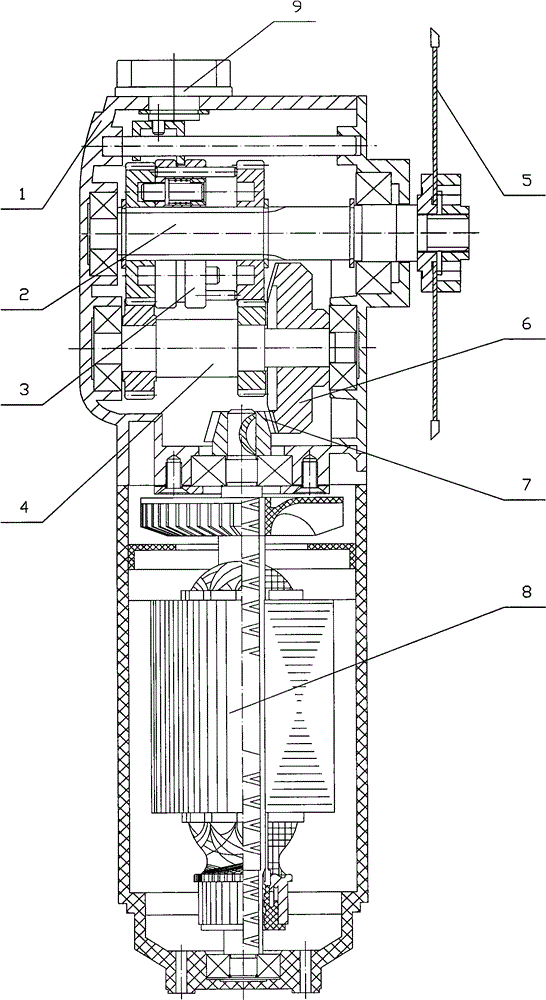

[0021] Depend on figure 1 The structure schematic diagram of the electric cutting angle grinder shown in the prior art shows that it includes a motor 8' located in the housing 1', a small bevel gear 7' and a large bevel gear 6' meshing with each other, an intermediate shaft 4' and an output The shaft 2', the output shaft of the motor 8' is connected to the small bevel gear 7', the large bevel gear 6' is connected to the intermediate shaft 4', and the intermediate shaft 4' and the output shaft 2' are both rotatably connected to the housing 1 'Inside, and connected by a set of meshing gears—the first gear 10' and the second gear 11'—the end of the output shaft 2' protruding from the housing 1' is connected with a cutting blade or a grinding wheel 5'.

[0022] When in use, turn on the power supply, and the rotation of the motor shaft wi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap