Linear array camera-based in-place grinding wheel quick full-field detection method and system

A line-scan camera and detection method technology, applied in the direction of measuring devices, image data processing, instruments, etc., can solve the problems of slow detection speed, unsatisfied rapidity, and difficult calculation of wear particle density, etc., to achieve strong mobility, Ease of use and light system effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0050] In order to solve various deficiencies in the prior art, the present invention provides a method and system for rapid full-field detection of in-position grinding wheels based on a line array camera. Using the working principle of the line array camera, the entire field surface of the grinding wheel can be quickly and accurately obtained Two-dimensional morphology can be applied to in-situ detection and offline detection.

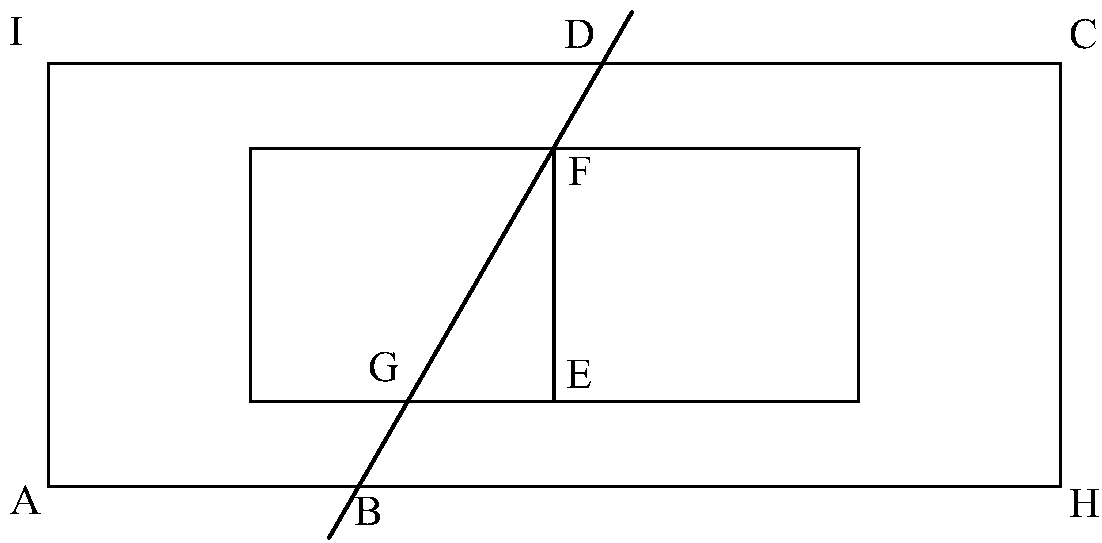

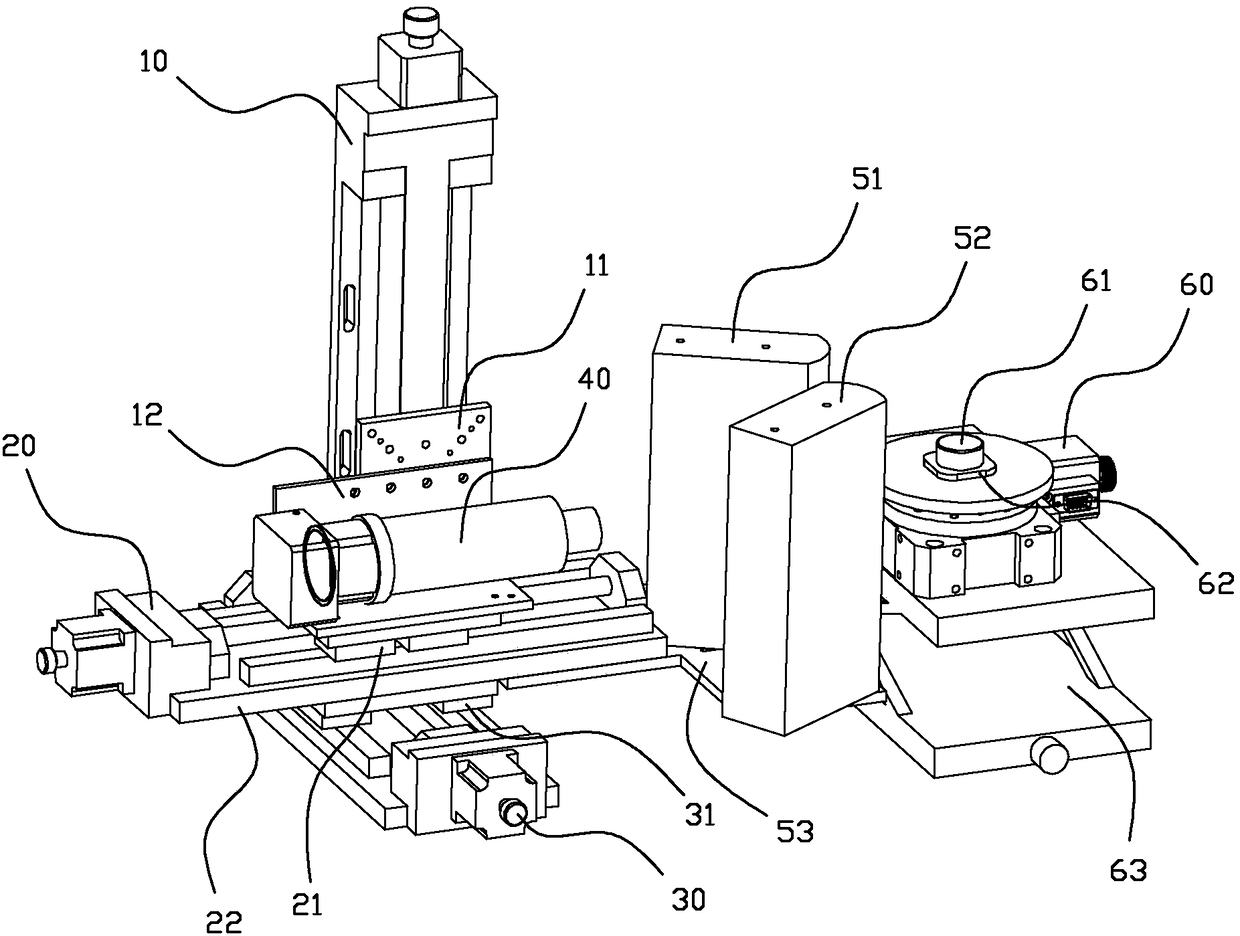

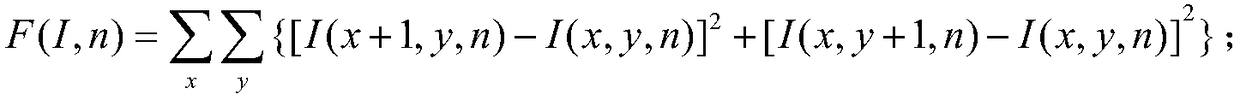

[0051] A fast full-field inspection method for an in-position grinding wheel based on a line array camera. The line array camera 40 is driven by a three-axis translation mechanism, and moves up, down, left, right, back and forth relative to the grinding wheel; the line array camera 40 is controlled by the three-axis translation mechanism to align with the grinding wheel. The position to be detected, and the direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com