Adjustable type shaking polishing equipment

An adjustable and equipment technology, applied in the direction of grinding/polishing equipment, metal processing equipment, grinding machines, etc., can solve the problems of low polishing efficiency and long time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

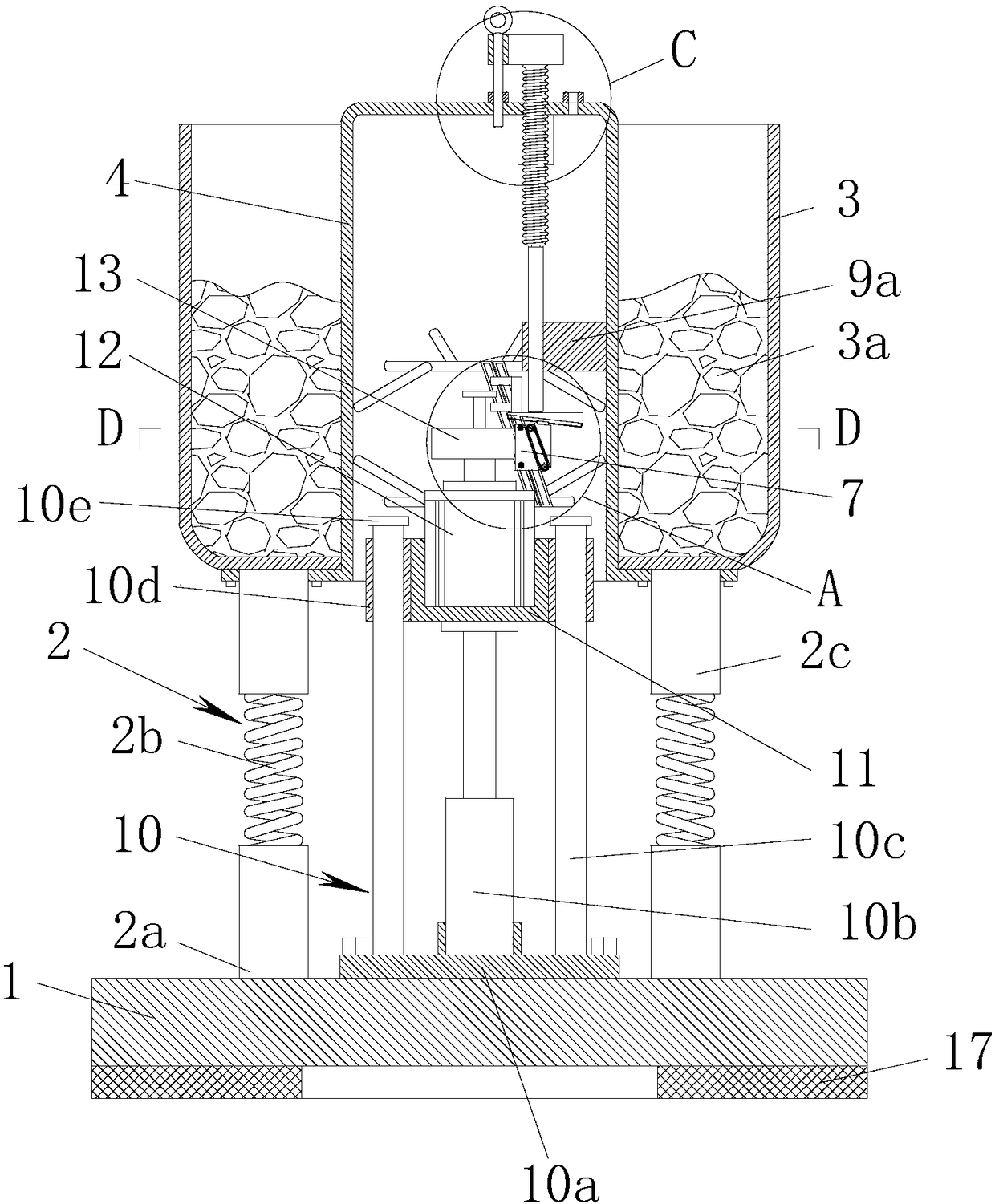

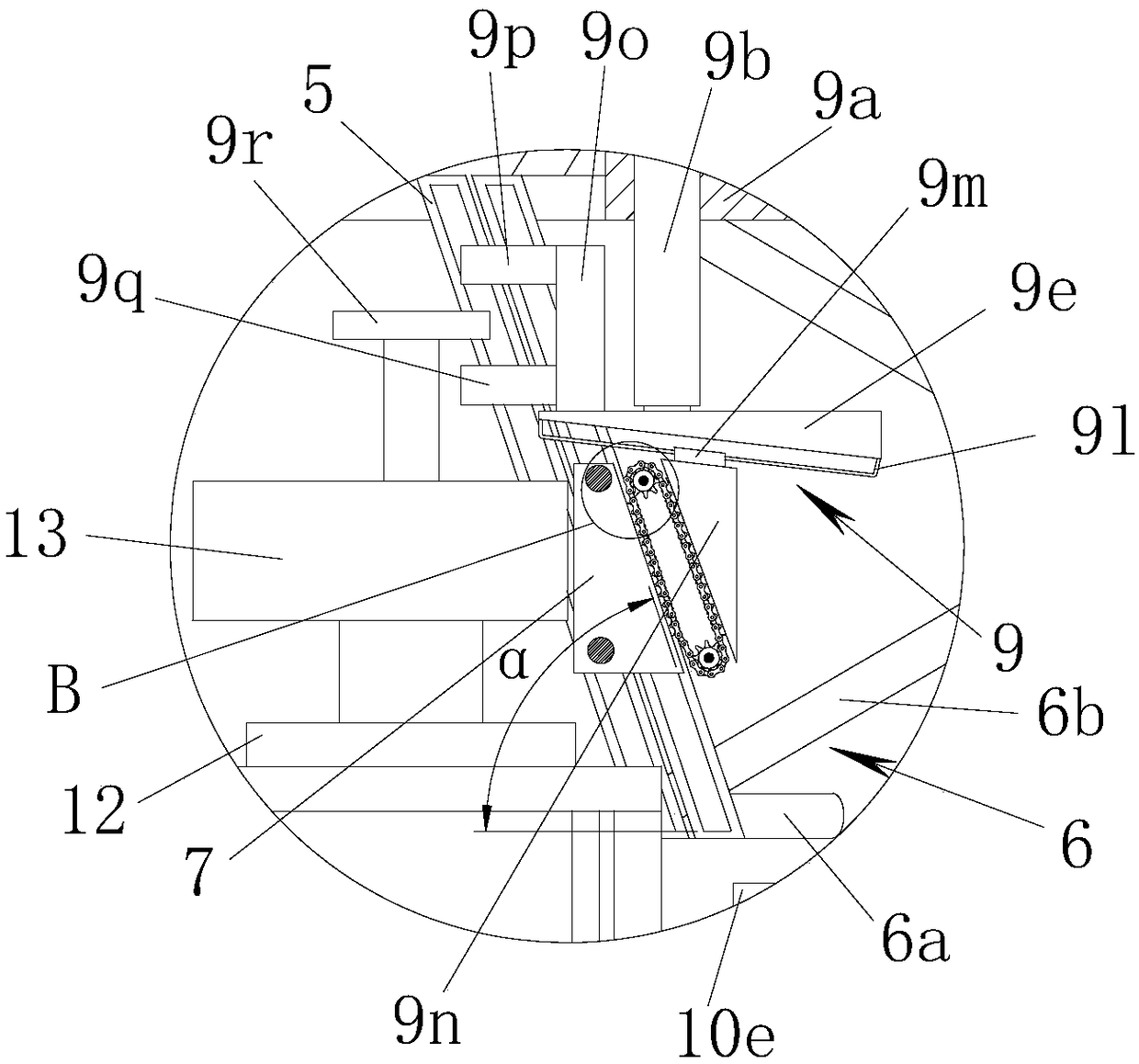

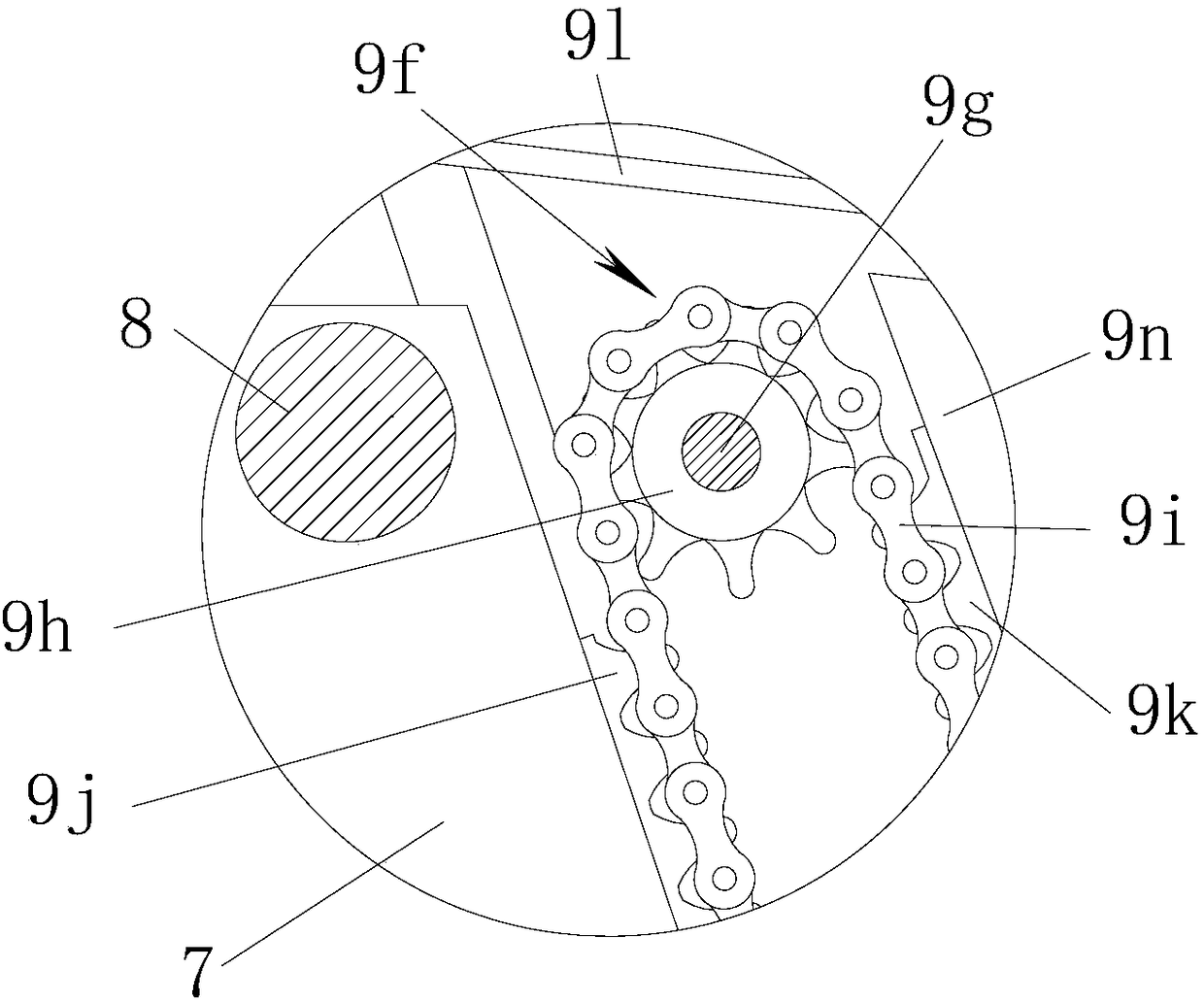

[0026] refer to Figure 1 to Figure 7 As shown, an adjustable vibratory polishing device of the present invention includes a base 1, and a buffer washer 17 is arranged at the bottom of the base 1 . A shock tube 3 is connected above the base 1 through a buffer mechanism 2. The buffer mechanism 2 is composed of at least two buffer assemblies. In this embodiment, there are four buffer assemblies along the circumference. The buffer assembly is composed of a first mounting sleeve 2a disposed on the base 1, a buffer spring 2b disposed in the first mounting sleeve 2a, and a second mounting sleeve 2c disposed at the free end of the buffer spring 2b. The second mounting sleeve 2c is fixedly connected with the shock tube 3 . Through the buffer mechanism, the vibration of the equipment can be offset to prevent the vibration from being transmitted to the base.

[0027] A mounting hole is provided at the bottom center of the shock tube 3, and a vibration tube 4 with an opening facing the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com