High-accuracy burr polishing mechanism used between gear teeth

A gear teeth, high-precision technology, applied in the direction of grinding racks, grinding machine parts, belts/chains/gears, etc., can solve the problems of not meeting the needs of manufacturers, low cleaning efficiency, and reduced product quality. Improve the polishing effect, improve the practicality and improve the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

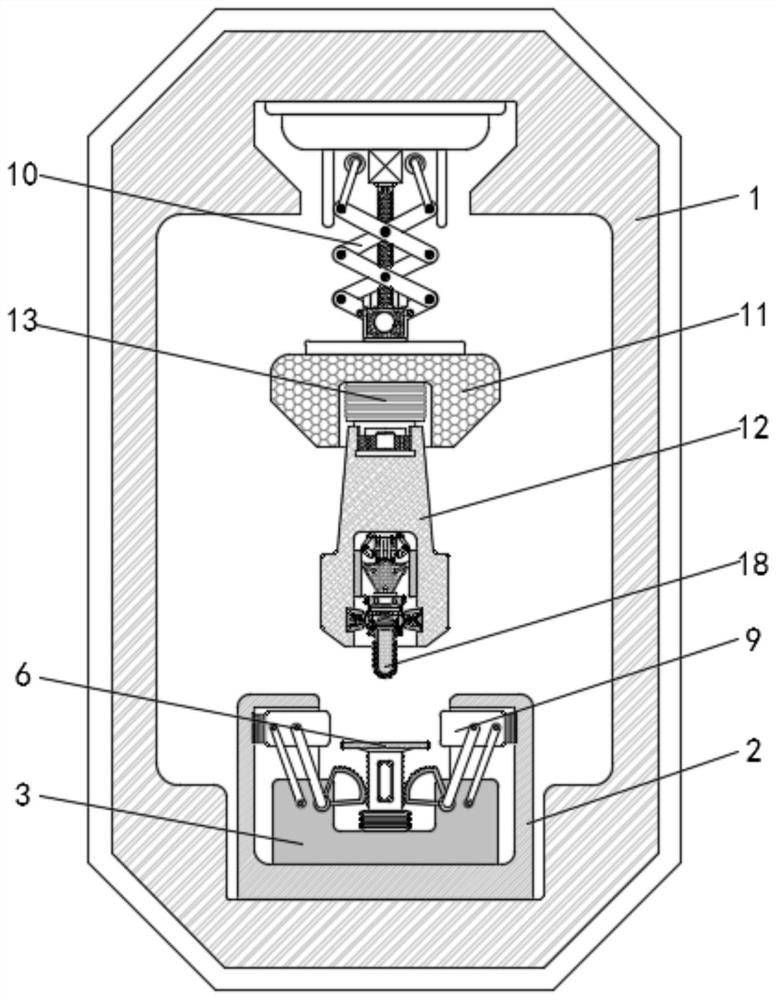

[0023] The present invention will be further described below in conjunction with accompanying drawing:

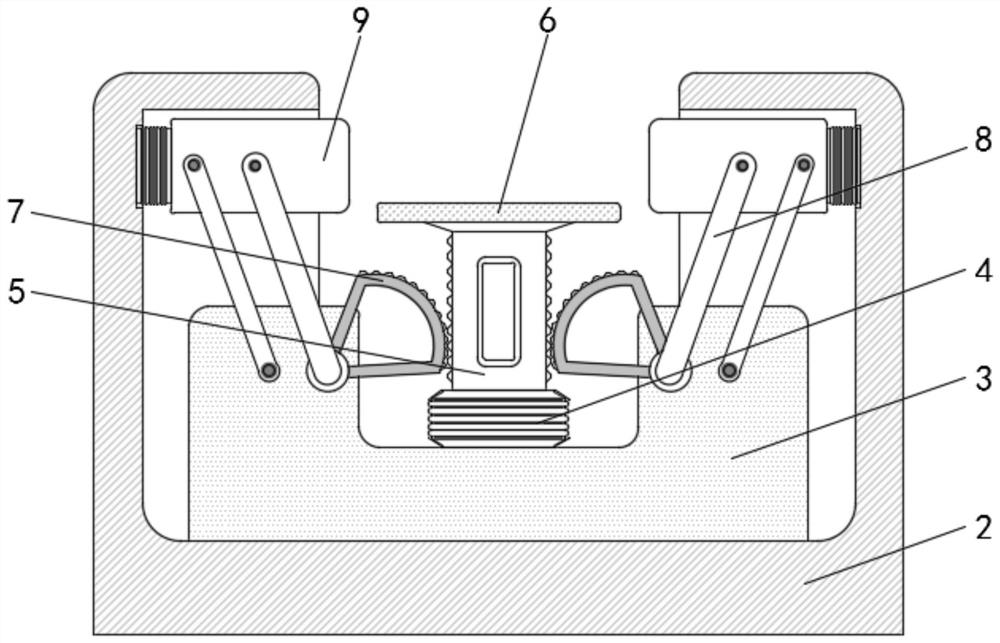

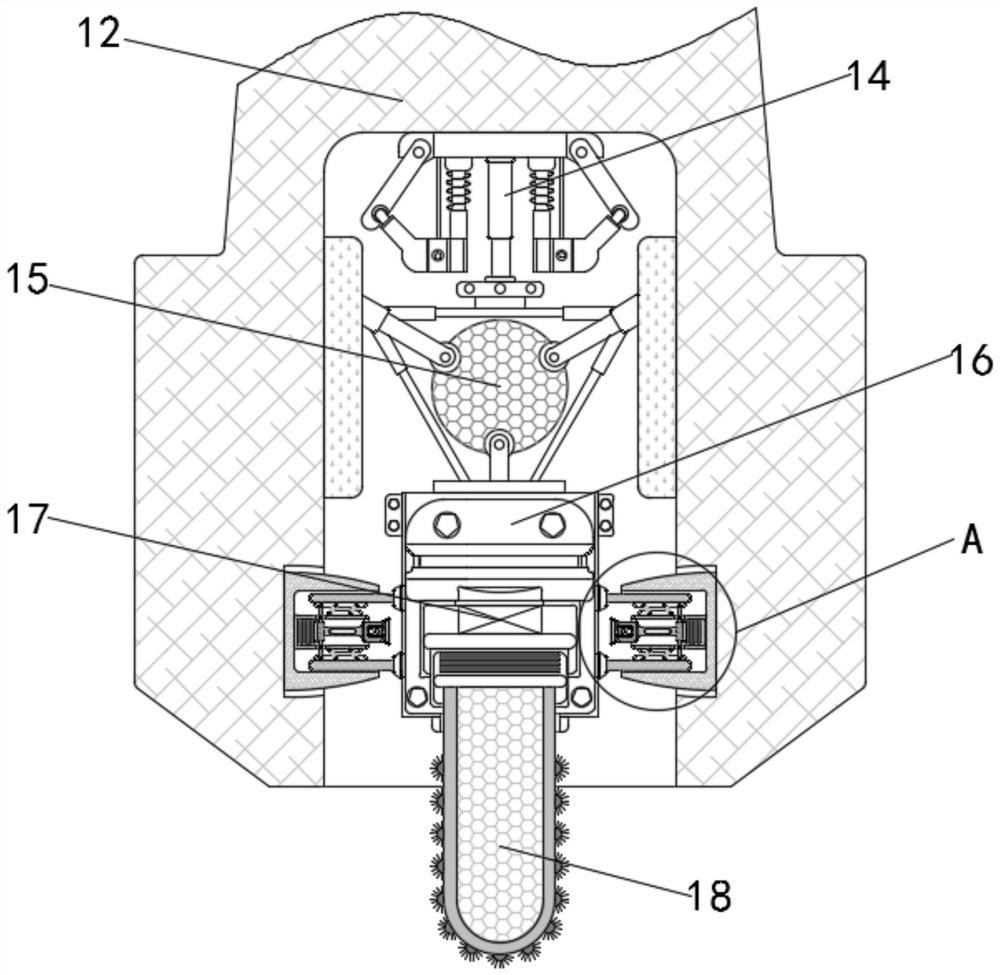

[0024] as attached figure 1 To attach Figure 4 Shown:

[0025] The invention provides a high-precision gear interdental burr polishing mechanism, which includes a main body 1, a housing 2 is installed at the bottom of the inner wall of the main body 1, and a fixed base 3 is installed inside the housing 2, and the inside of the fixed base 3 A support air cushion 4 is installed, a support column 5 is fixedly installed on the upper side of the support air cushion 4, a bearing platform 6 is fixedly installed on the upper end of the support column 5, racks are arranged on the left and right sides of the support column 5, and the support column 5 utilizes a toothed The bar is meshed with the movable toothed plate 7, and the movable toothed plate 7 is movably equipped with a movable connecting rod 8, and the upper end of the movable connecting rod 8 is movably installed with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com