Vibration cylinder structure for vibration polishing equipment

A vibrating cylinder and equipment technology, applied in grinding/polishing equipment, machine tools suitable for grinding workpiece edges, metal processing equipment, etc., can solve the problems of long time consumption and low polishing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

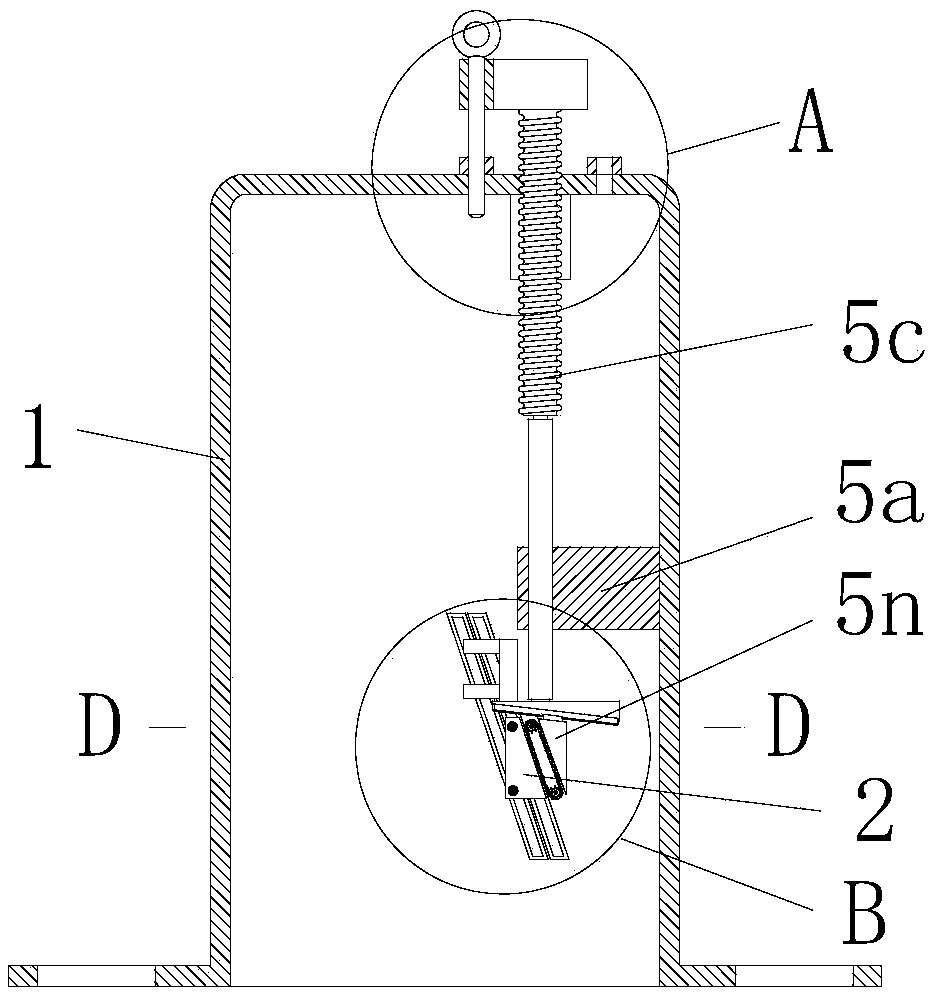

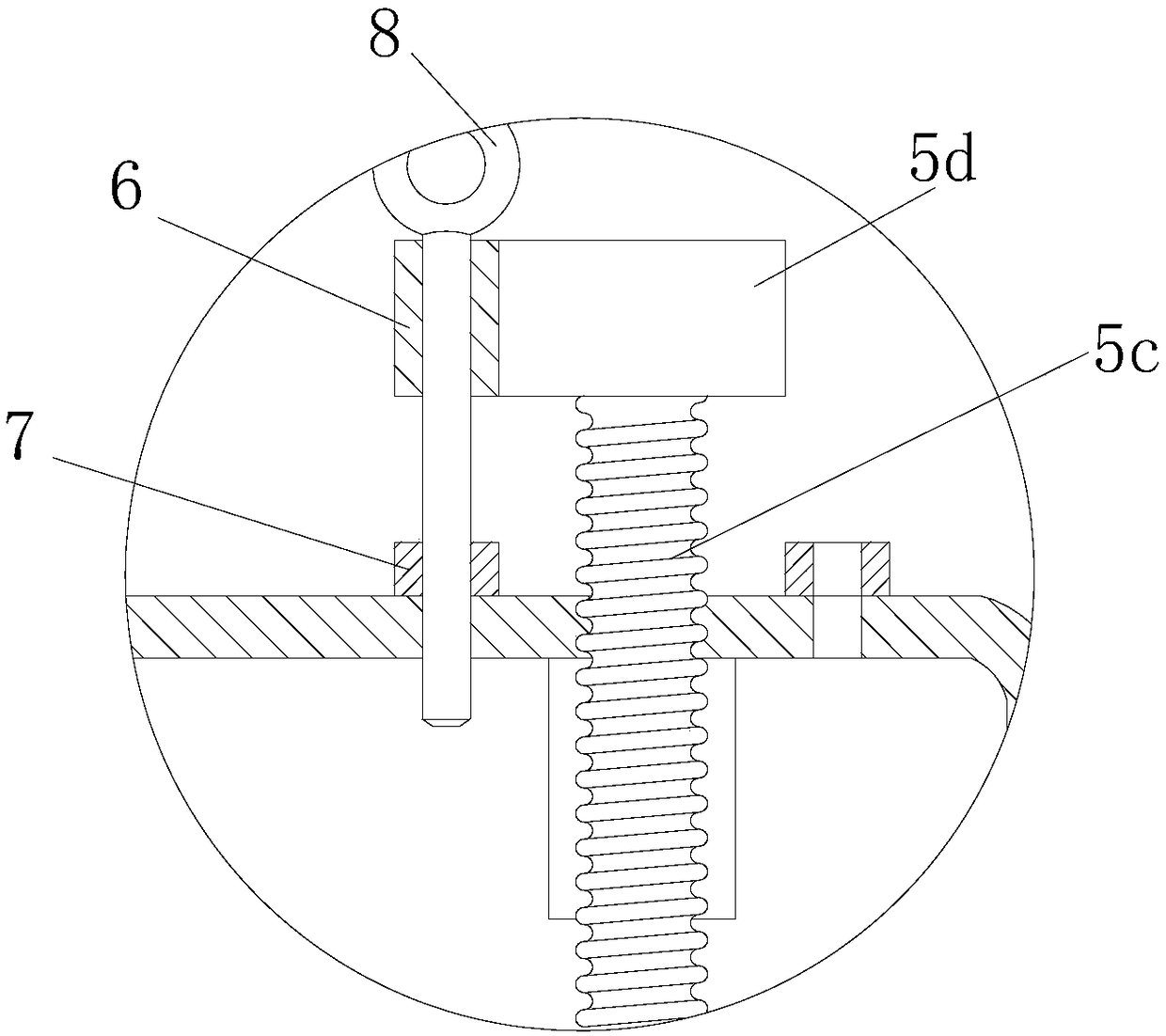

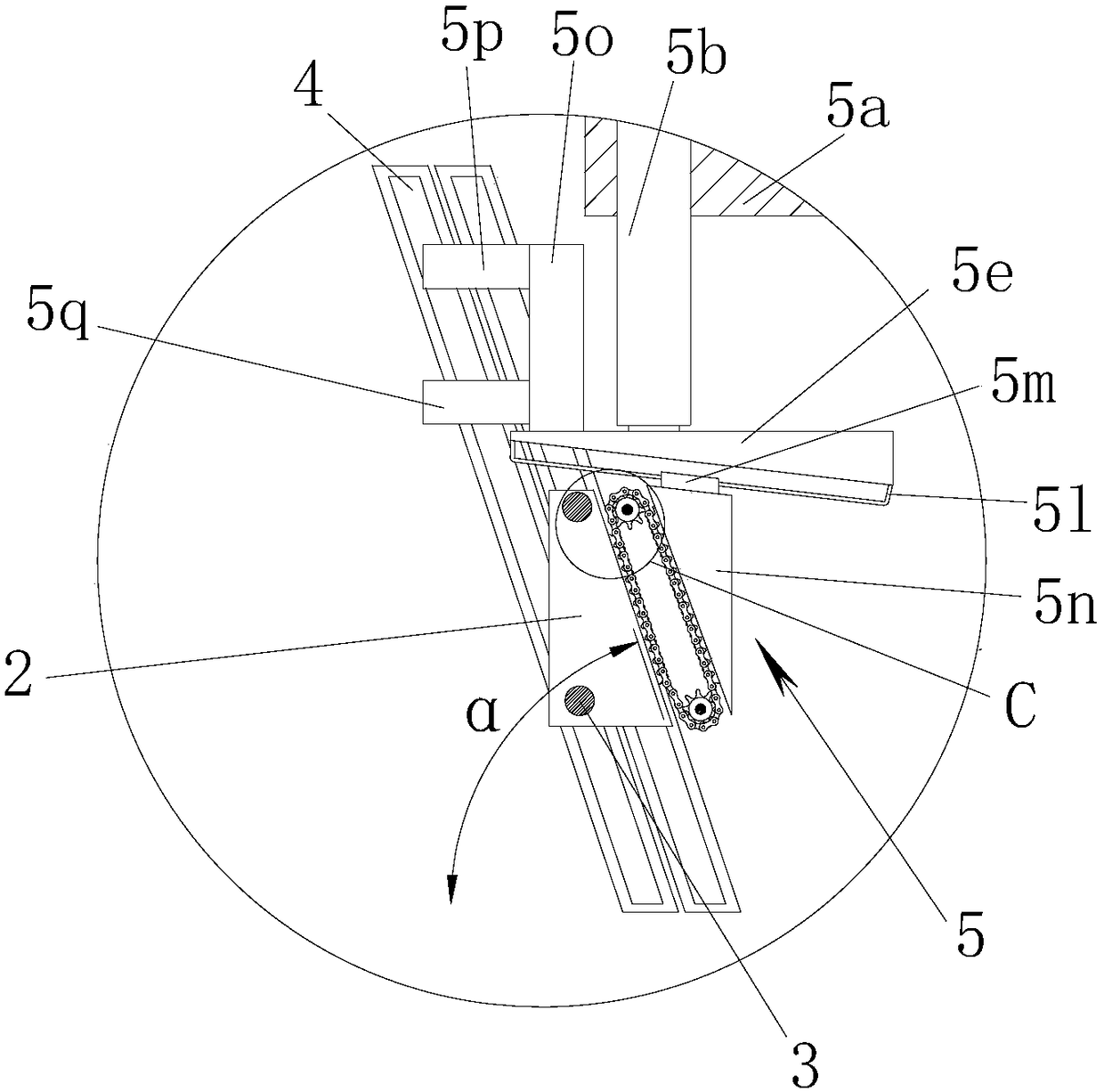

[0022] refer to Figure 1 to Figure 7 As shown, a vibrating tube structure used for vibrating polishing equipment of the present invention includes a vibrating tube 1 with one side open, and a vibrating seat 2 is arranged inside the vibrating tube 1, and the vibrating seat 2 is connected to the vibrating tube through a vibrating rod 3. Cartridge 1 is connected. The vibration base 2 corresponds to the external vibration driving mechanism. The external vibration driving mechanism can be composed of a driving motor, an eccentric wheel connected with the power output shaft of the driving motor, and an induction turntable connected with the eccentric wheel through a rotating shaft. The vibration seat corresponds to the eccentric wheel.

[0023] The vibrating tube 1 is provided with vibrating conduction grooves 4 which match with the two ends of the vibrating rod 3 . The included angle α between the two groups of vibration conducting grooves 4 and the horizontal plane is 65-80°. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com