A kind of vibration lifting device for casting

The technology of a vibrating device and a rotary device, which is applied in the field of vibrating mold lifting devices for casting, can solve the problems that it is difficult to ensure that the lifting force and the center of gravity of the mold are on a vertical line, the mold cavity is damaged, and the labor load is increased. Ingenious design, stable mold, and the effect of improving casting production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments and illustrations.

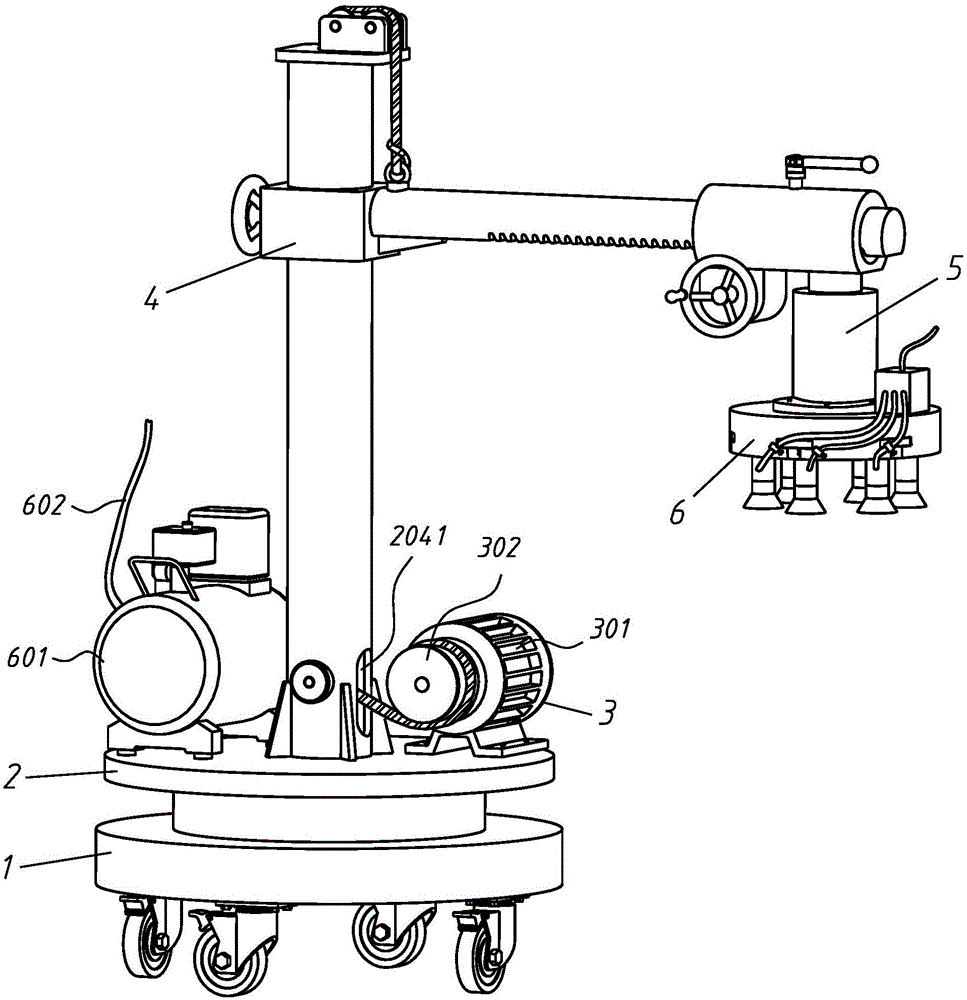

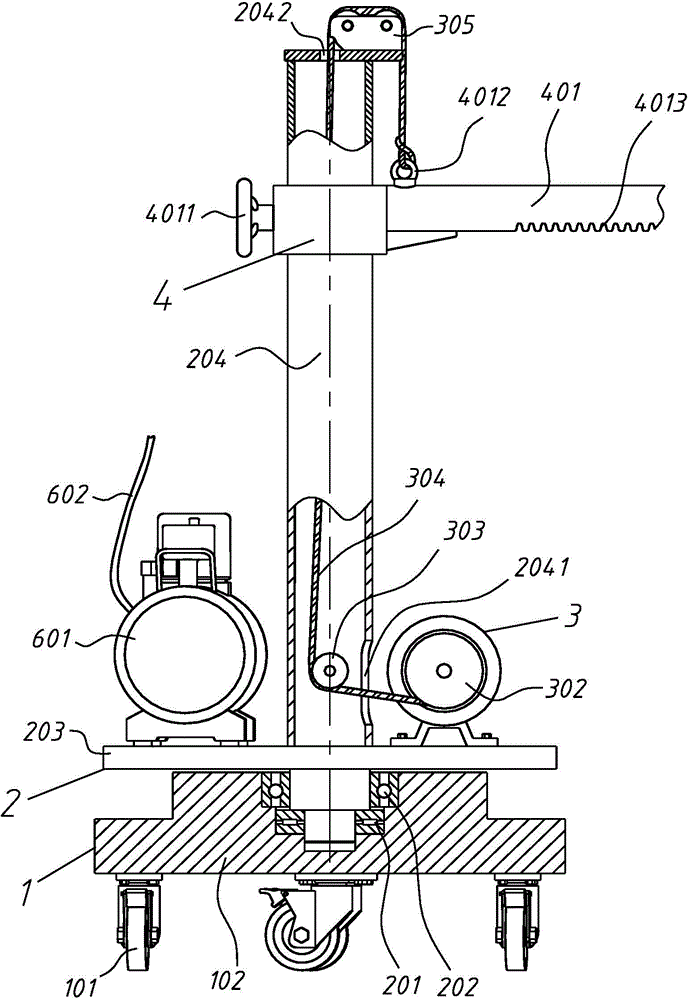

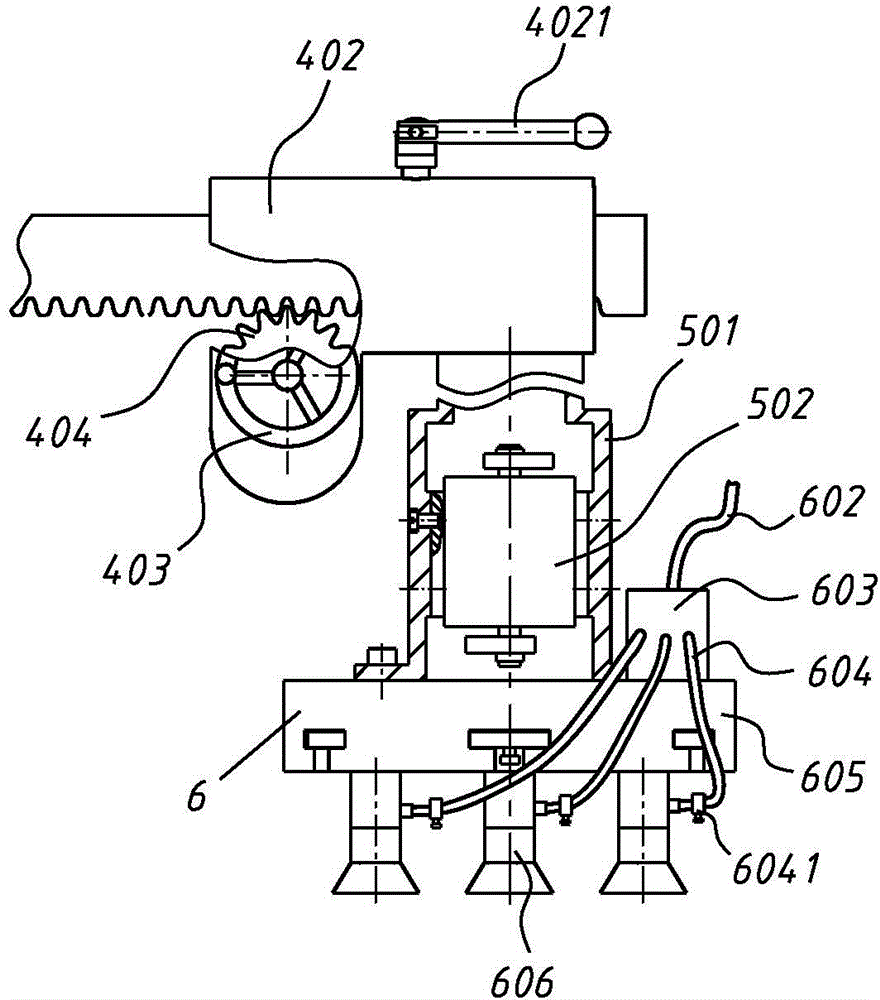

[0018] Such as figure 1 and figure 2 As shown, a vibration ejector device for casting is composed of a moving seat 1, a rotary device 2, a lifting device 3, a traverse device 4, a vibrating device 5 and an adsorption device 6, wherein the moving seat 1 is composed of a universal wheel 101 and base 102, the universal wheel 101 adopts a universal wheel with brakes, when the mold is ejected, the vibration ejector device is moved to the mold, and then the universal wheel 101 is locked and braked , and then carry out mold removal. Turning device 2 is made up of thrust bearing 201, roller bearing 202, turntable 203 and turning column 204, when in use, by turning turntable 203, the casting mold of different positions can be made...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com