Adjustable vibration cylinder structure

A vibrating cylinder, adjustable technology, applied in the direction of grinding machine parts, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of low polishing efficiency and long time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

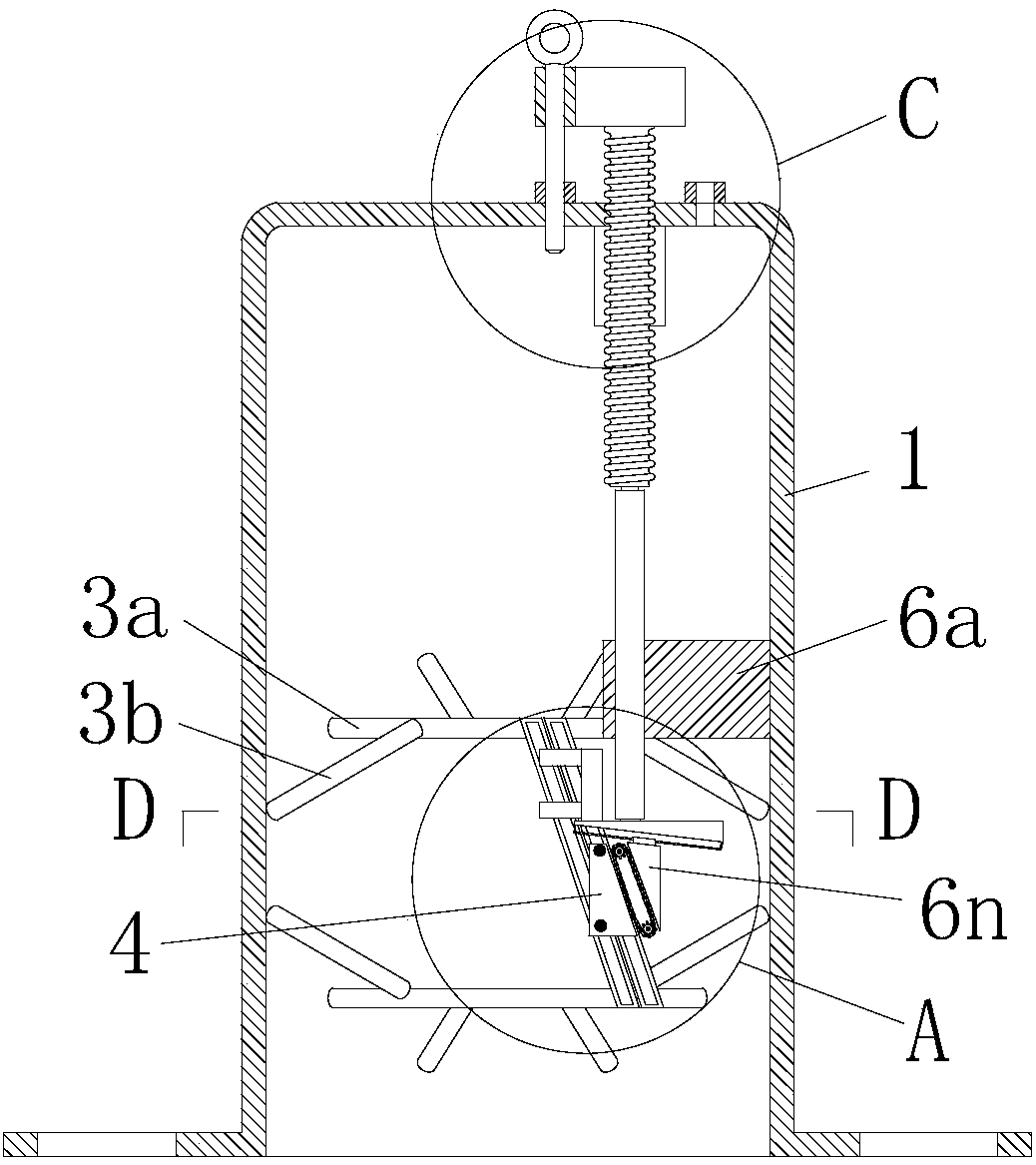

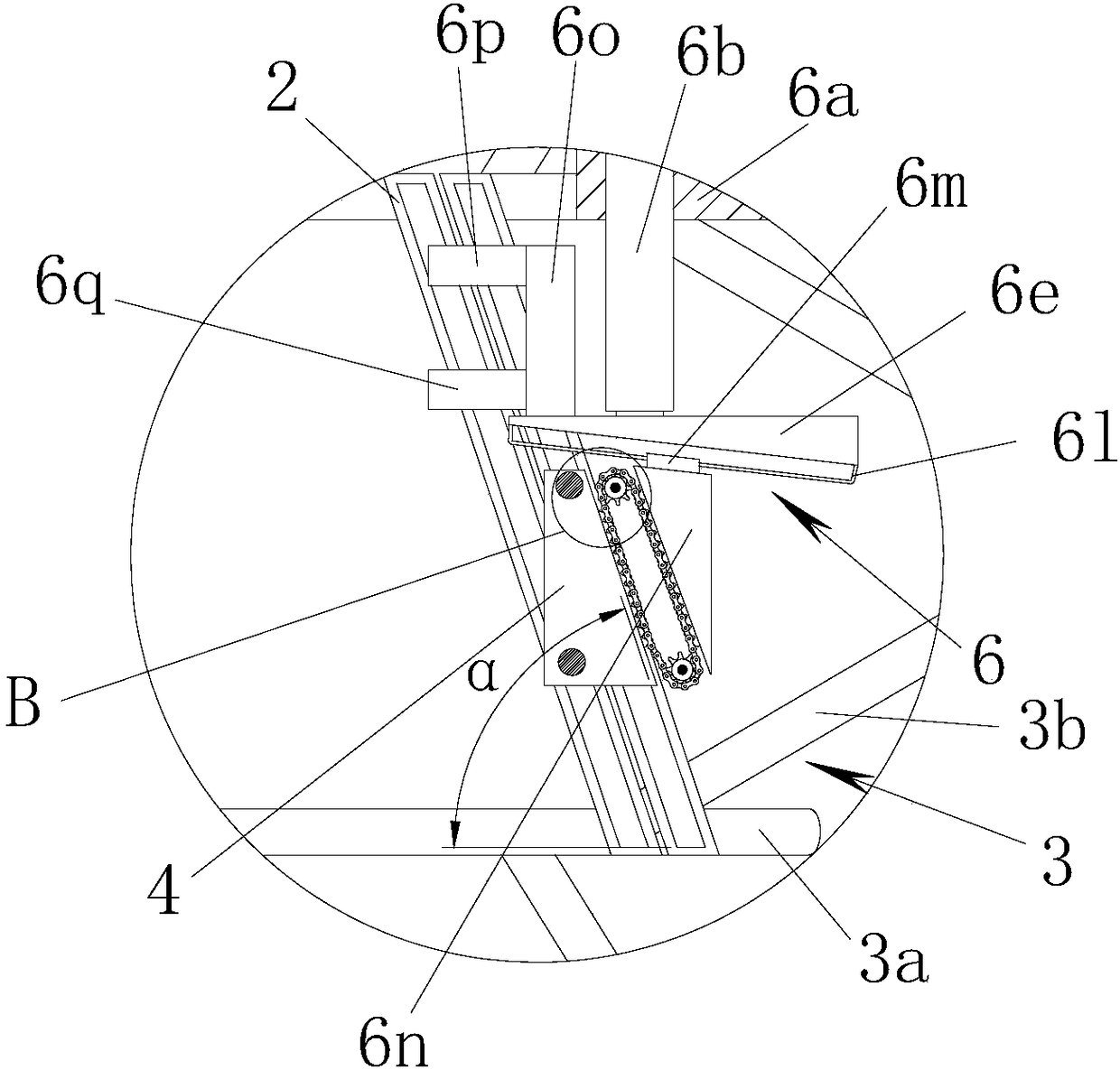

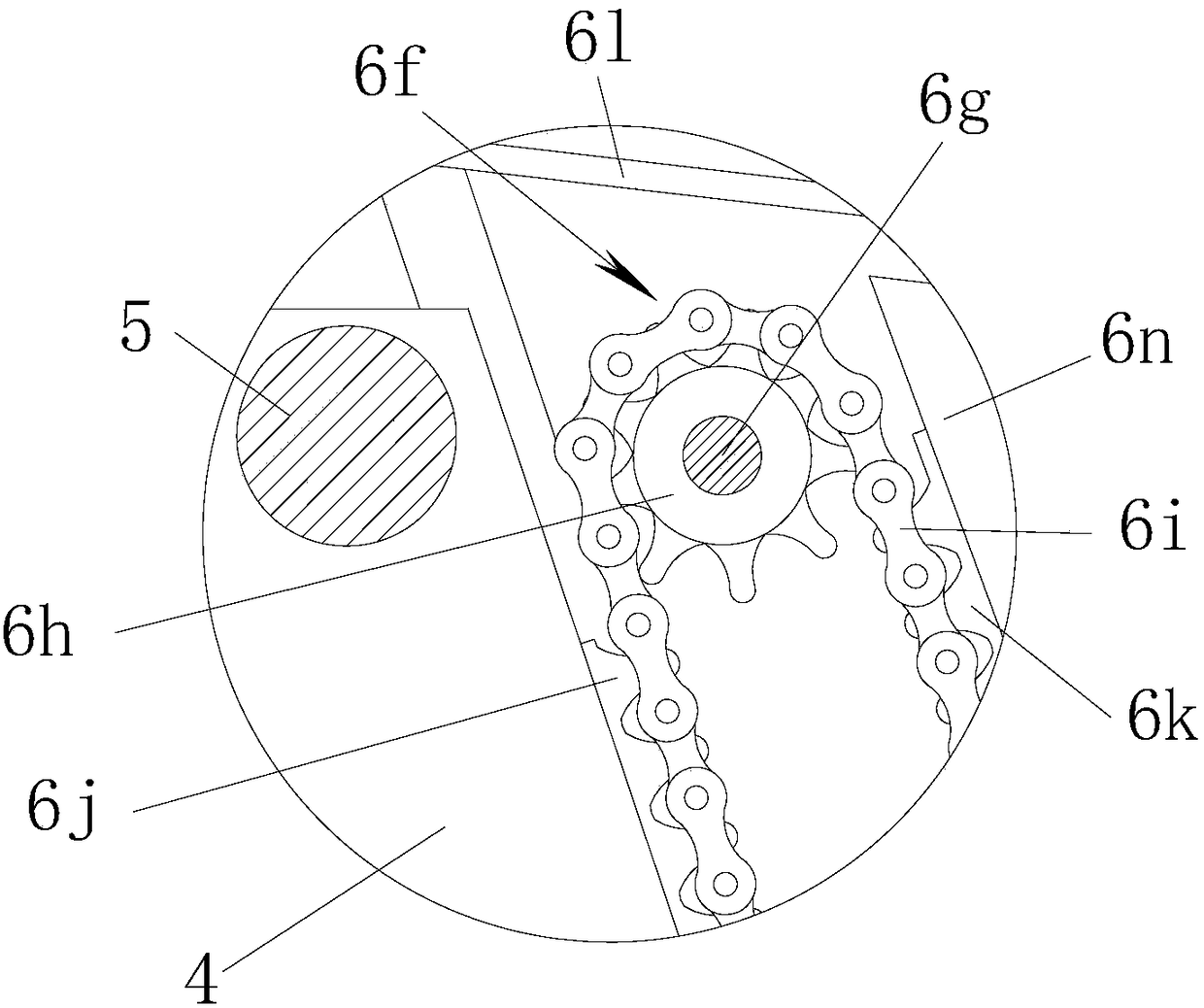

[0022] Refer to Figure 1 to Figure 7 As shown, an adjustable vibrating cylinder structure of the present invention includes a single-side open vibrating cylinder 1. The vibrating cylinder 1 is inclined and provided with two sets of vibration transmission grooves 2 opposite to each other. The two sets of vibration transmission grooves 2 respectively pass The corresponding vibration conduction fixing frame 3 is connected to the inner wall of the vibration cylinder 1; a vibration seat 4 is provided in the vibration cylinder 1, and the vibration seat 4 is connected to the vibration conduction groove 2 through a vibration rod 5. The included angle α between the vibration conducting groove 2 and the horizontal plane is 65-80°. Reasonable included angle can effectively produce and transmit vibration with the vibration base. The two ends of the vibrating rod 5 are provided with limit balls, and the limit balls are arranged in the vibration transmission groove 2. The vibration base 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com