Vibration polishing equipment for pipe fitting polishing

A pipe fitting and equipment technology, applied in the field of vibration polishing equipment for pipe fitting polishing, can solve the problems of long time consumption and low polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

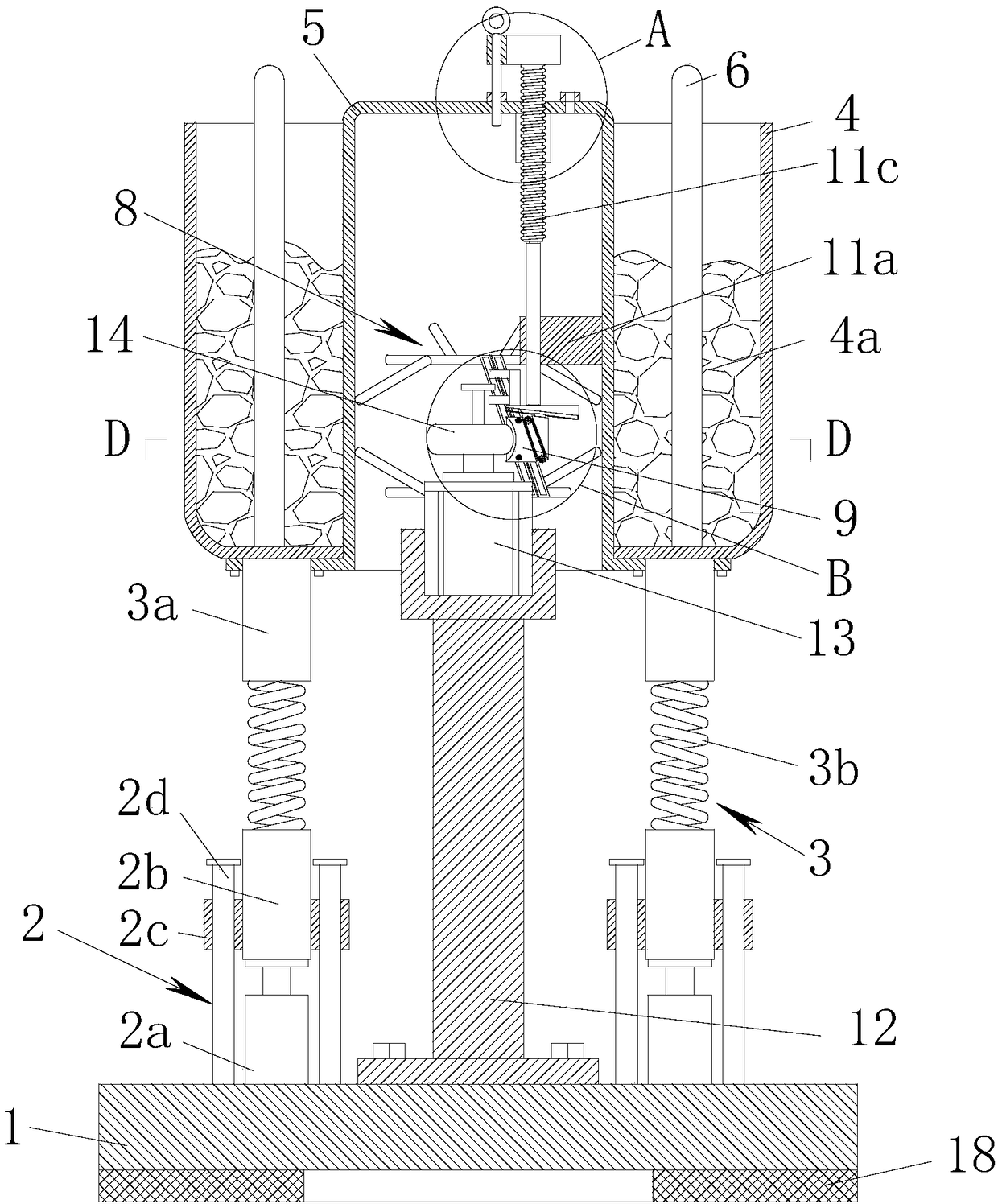

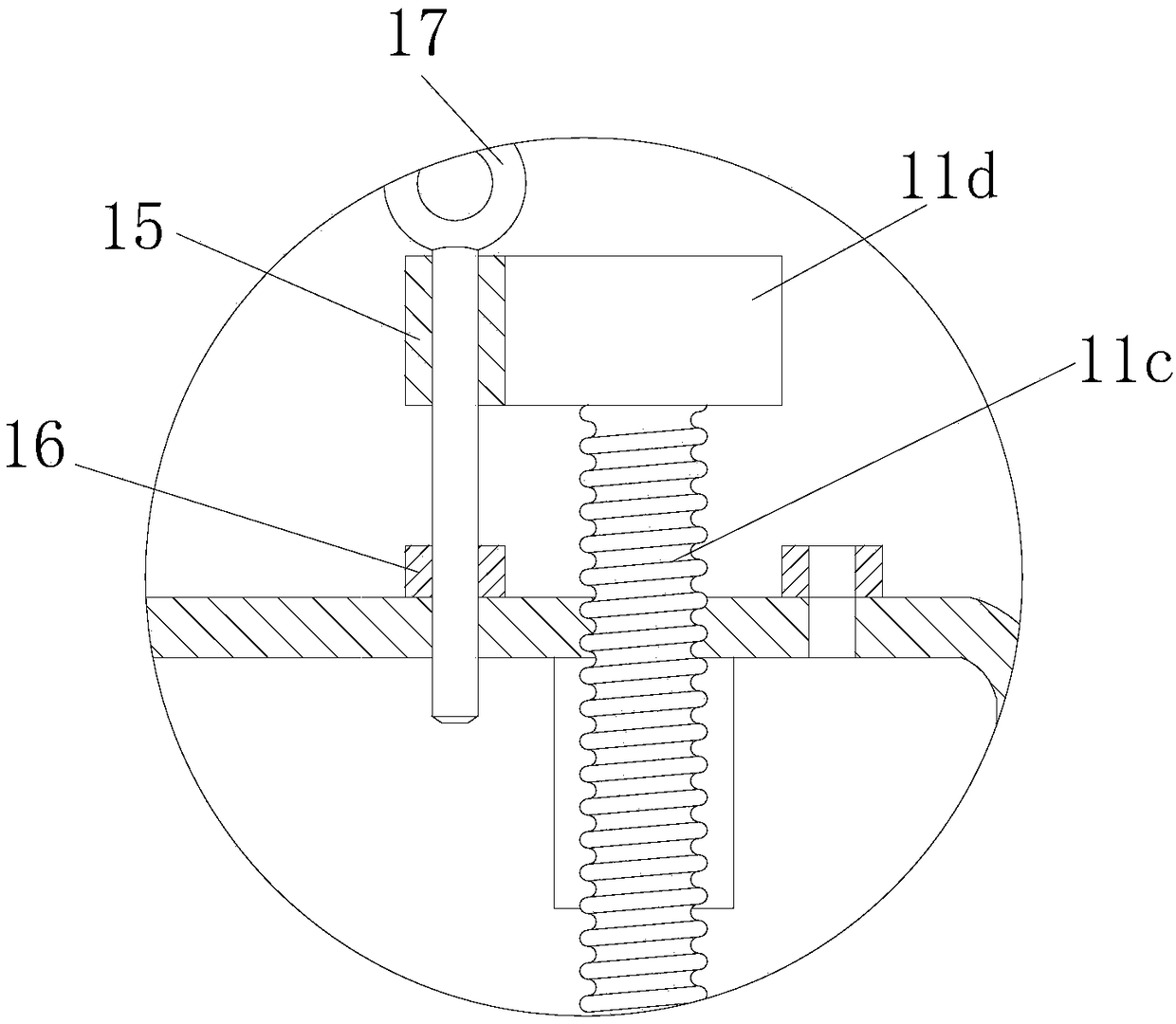

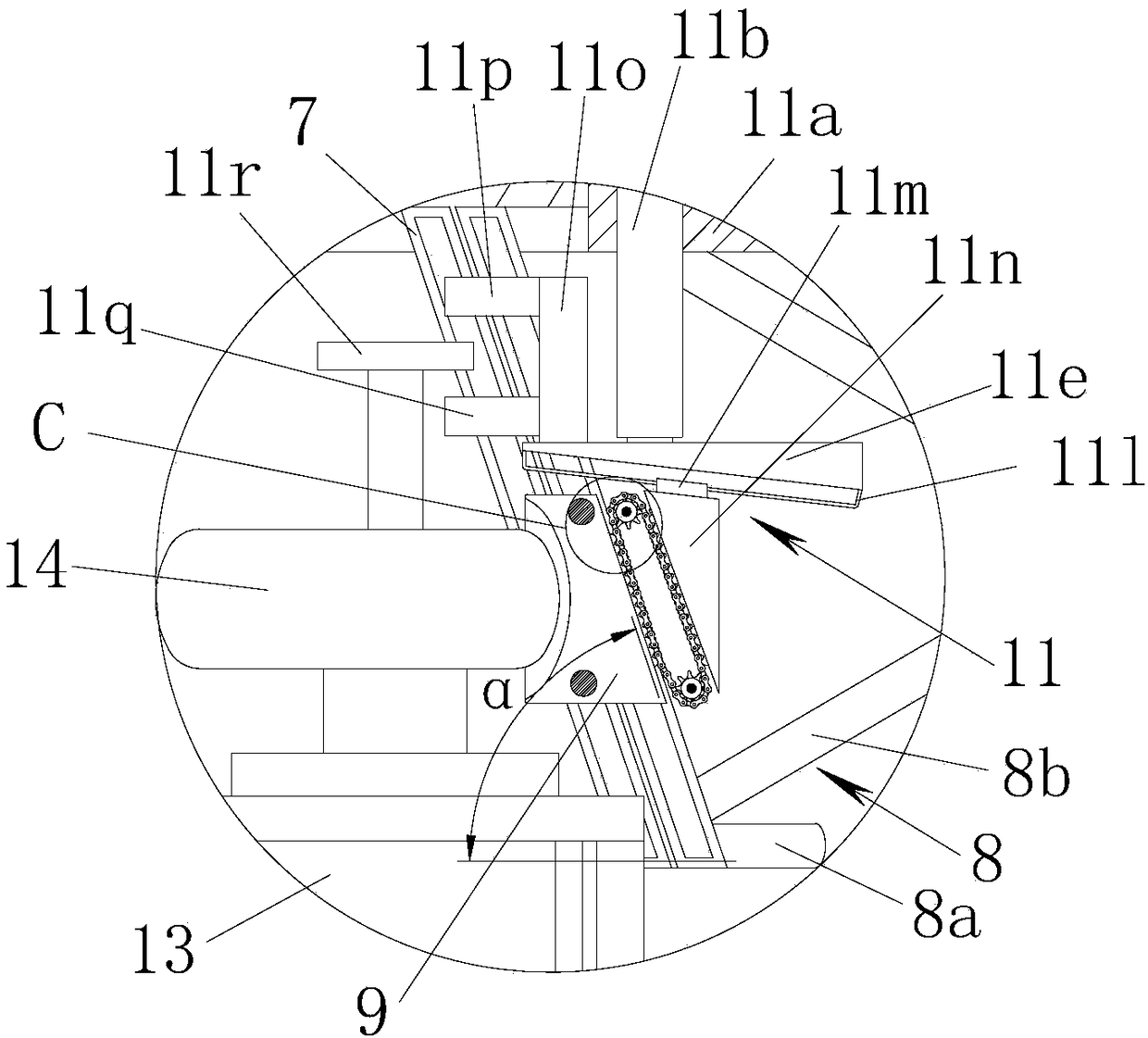

[0027] refer to Figure 1 to Figure 7 As shown, a vibratory polishing device for pipe fitting polishing according to the present invention includes a base 1, and a buffer washer 18 is arranged at the bottom of the base 1 . The base 1 is provided with a first lifting adjustment mechanism 2, a buffer mechanism 3 is arranged on the first lifting adjustment mechanism 2, and a shock tube 4 is arranged on the buffer mechanism 3. Specifically, the first lifting adjustment mechanism 2. It is composed of a number of lifting adjustment components that are evenly spaced along the circumference of the support 12. Each lifting adjustment component is composed of a lifting cylinder 2a arranged on the base 1 along the vertical direction, and a lifting seat 2b arranged at the free end of the piston rod of the lifting cylinder 2a. 1. The guide rings 2c arranged on the outer wall of the lifting seat 2b along the circumferential direction and the guide columns 2d corresponding to each guide ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com