Robot with over-obstacle function

A robot and functional technology, applied in the field of robots with obstacle crossing function, can solve the problems of cumbersome equipment, time-consuming and labor-intensive, and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

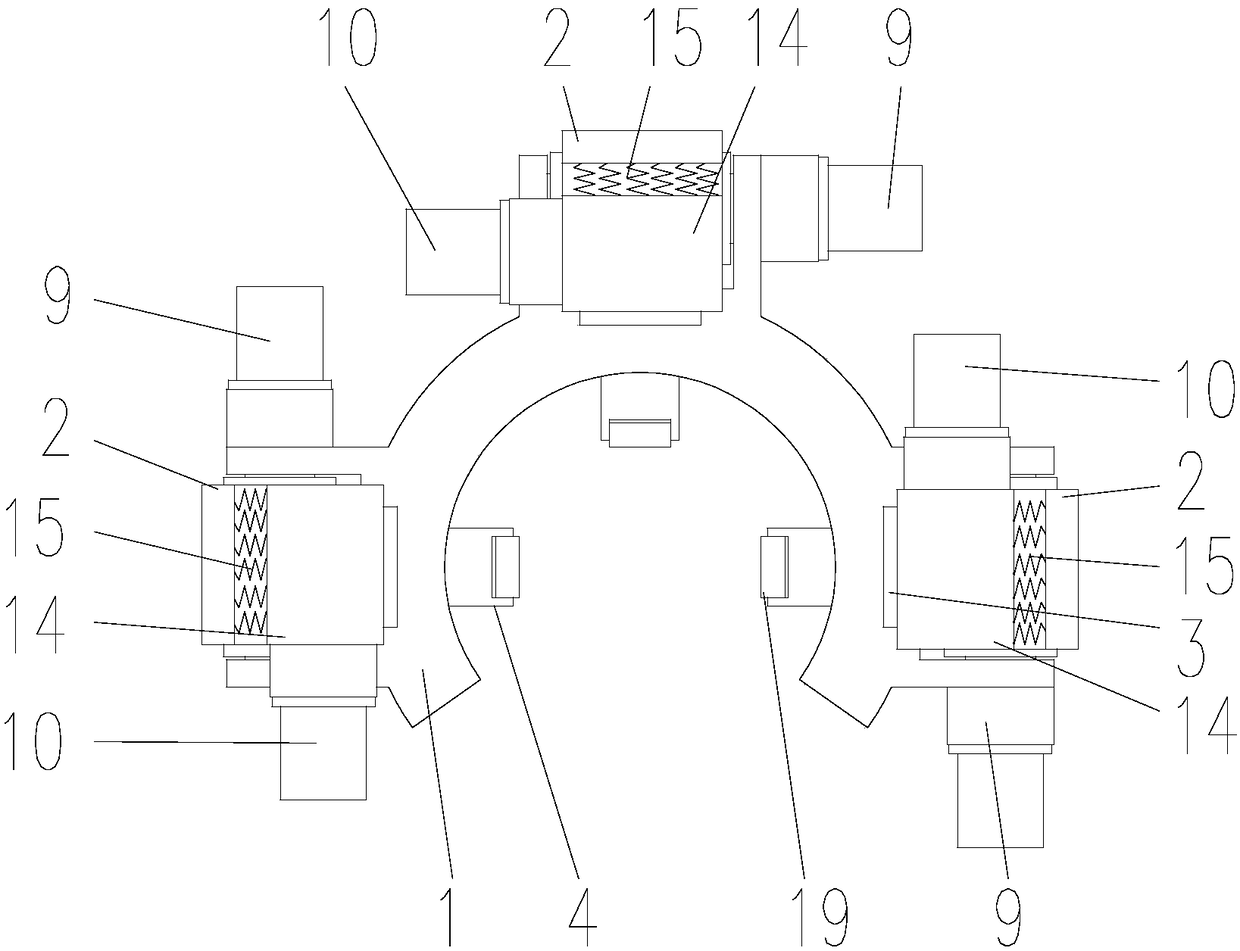

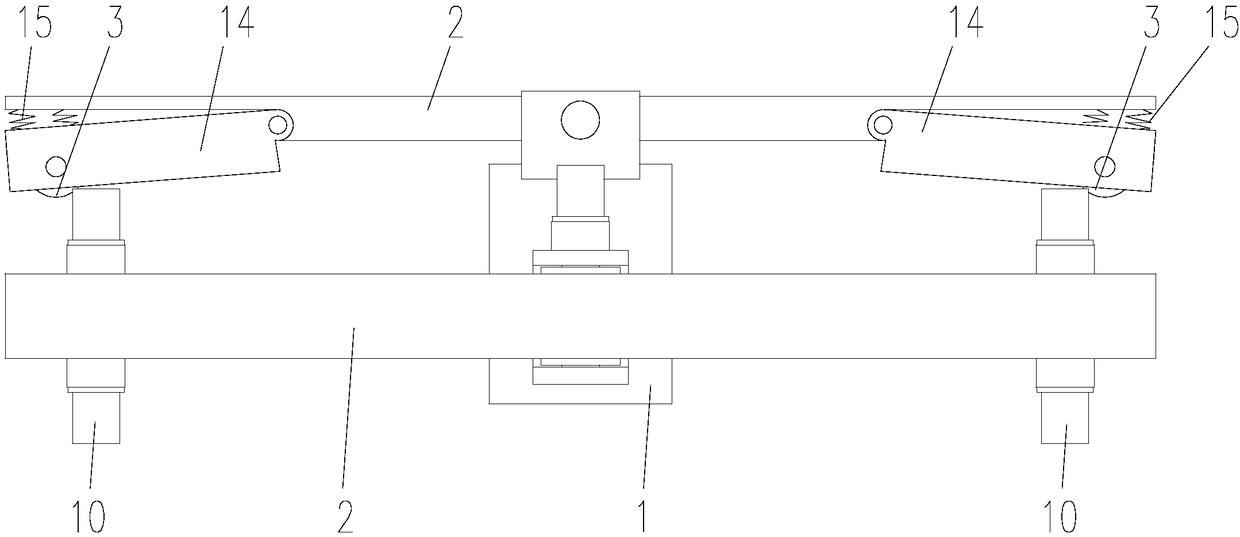

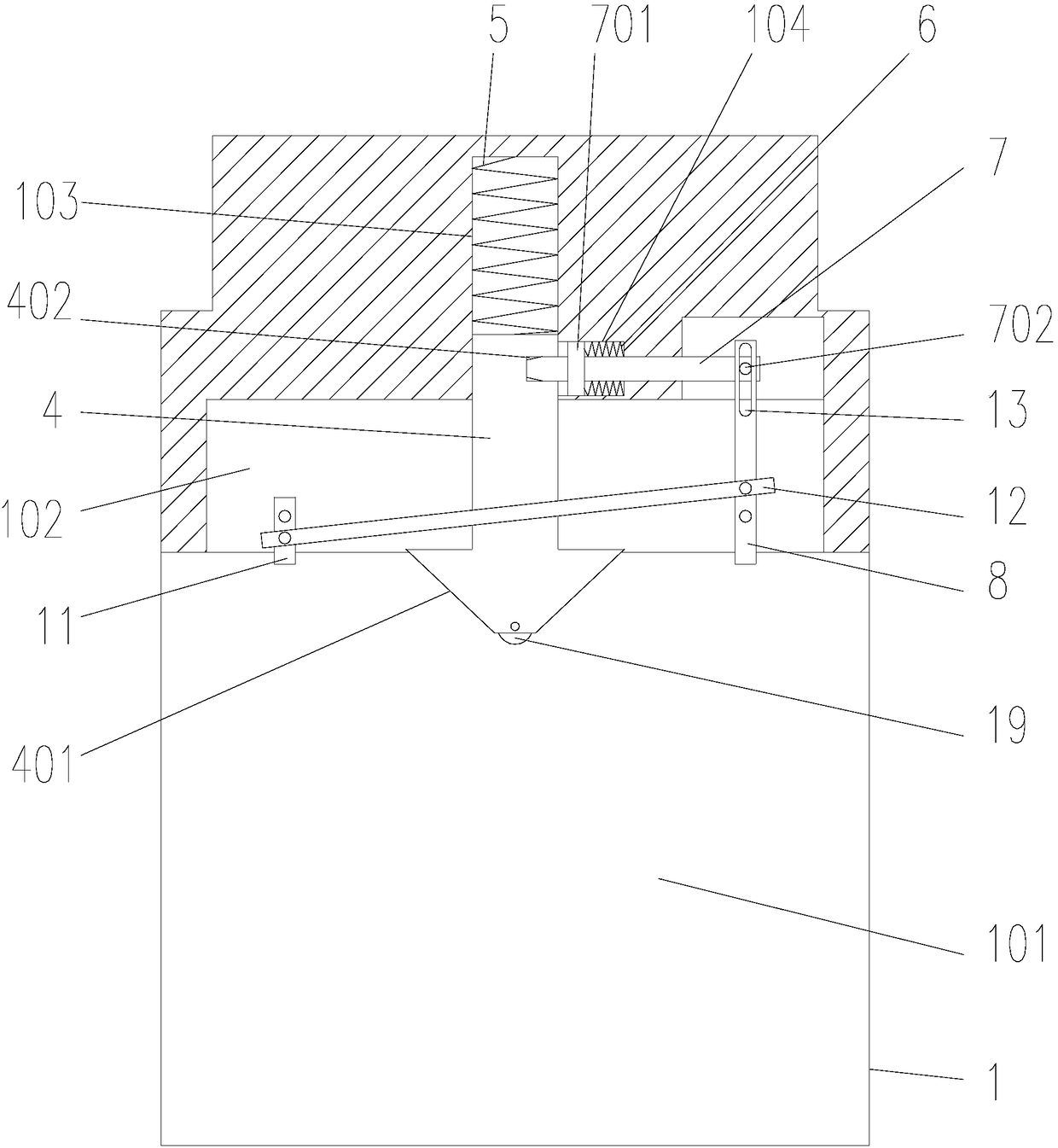

[0024] like Figure 1-9Shown, a kind of robot with obstacle-surmounting function, comprises base 1, connecting rod 2, roller 3, support plate 4, first spring 5, second spring 6, limit column 7 and first bar 8, described The connecting rod 2 is rotatably arranged on the base 1, the base 1 is provided with a first motor 9 for driving the connecting rod 2 to swing, and the two ends of the connecting rod 2 are provided with the rollers 3, so The connecting rod 2 is provided with a second motor 10 for driving the roller 3 to rotate, the first motor 9 is fixedly connected to the base 1, and the output of the first motor 9 is connected by transmission between the connecting rods 2, and the connecting rod 2 The center of rotation is located between the rollers 3 at both ends of the connecting rod 2, that is, the base 1 is located between the rollers 3 at both ends of the connecting rod 2, and the base 1 is provided with a notch 101 along the length direction of the connecting rod 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com