Rubber sealing plug for airtight test

A rubber seal and airtight test technology, applied in fluid tightness test, machine/structural component test, liquid tightness measurement using liquid/vacuum degree, etc., can solve test failure, unqualified, rush out, etc. problem, to achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

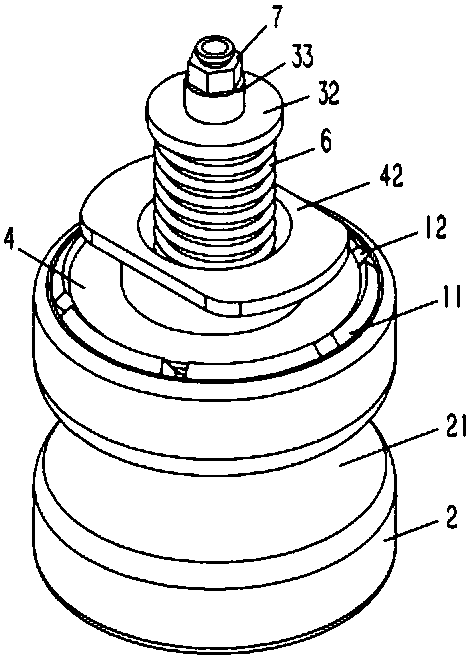

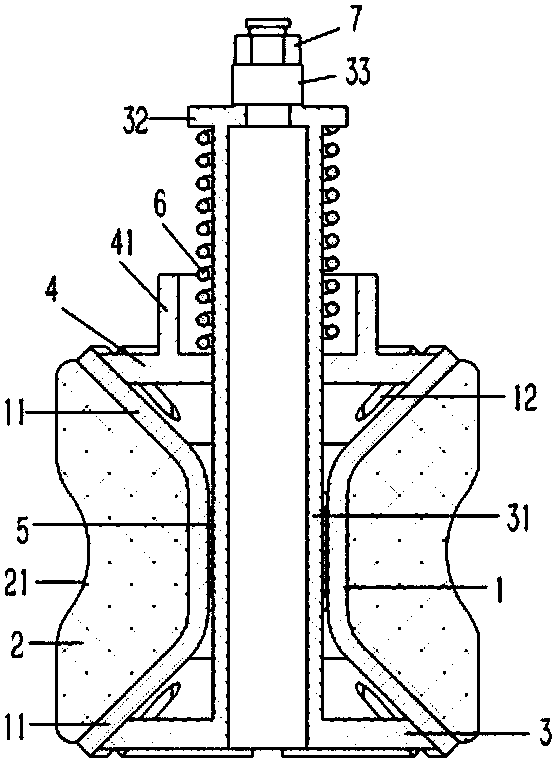

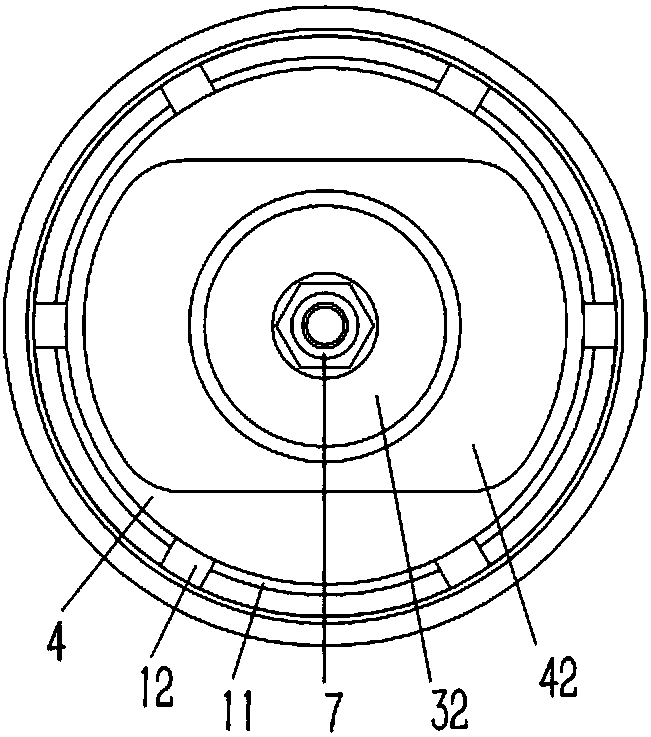

[0016] Example: see Figures 1 to 3 As shown, a rubber sealing plug for airtight testing includes a vertical outer sleeve 1, the upper and lower ends of the outer sleeve 1 are formed with conical tensioning sleeves 11, and there are several grooves formed on the tensioning sleeve 11. Cutting groove 12, the cutting groove 12 divides the tensioning sleeve 11 into several circular arc pieces, the outer rubber sleeve 2 is inserted into the upper sleeve of the outer sleeve 1, and the upper and lower inner walls of the outer rubber sleeve 2 are pasted and fixed on the outer wall of the tensioning sleeve 11 , the tension sleeve 11 at the lower end of the outer sleeve 1 is inserted with a truncated conical lower platen 3, the middle of the lower platen 3 is formed with a vertical inner tube 31, and the upper end of the inner tube 31 passes through the truncated upper platen 4 An annular retaining ring 32 is formed, and a threaded connection seat 33 is formed on the upper end surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com