Practical dust removing device

A dust collector and equipment technology, which is applied to the parts of the connection device, the device to prevent contact with live contacts, and electrical components, etc., can solve the problems of power failure of the dust collector, exposed power transmission port, unstable power supply connection, etc., and achieve Safe and stable power supply, simple and convenient operation, and good power supply stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

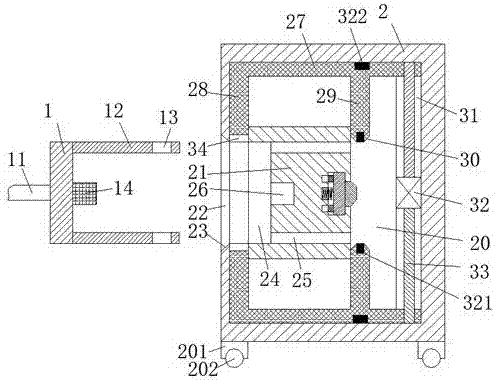

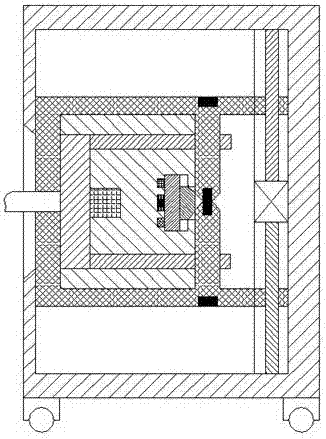

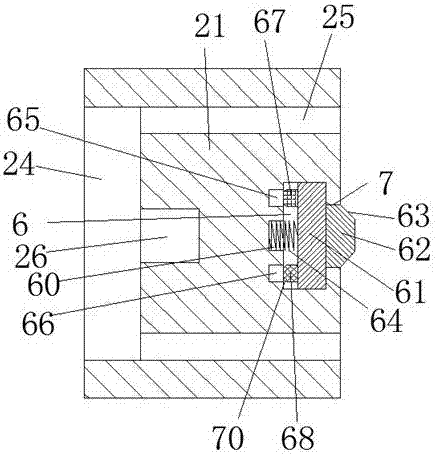

[0019] refer to Figure 1-4 The shown practical dust collector equipment includes a power transmission part and a power transmission seat connected to the dust collector through a cable 11. The power transmission part includes a push rod 1, and the front and rear ends of the right end surface of the push rod 1 are opposite to each other. There are two bolts 12, and the right ends of the two bolts 12 are provided with a slot 13, and the center of the right end of the push rod 1 is provided with a contact arm 14, and the power transmission seat includes a base 2, and the base The bottom of the base 2 is fixedly equipped with a foot column 201 aroun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com