Intelligent prestressed anchor plate and prestress monitoring method

A technology of prestressing and anchoring plates, which is applied in the measurement of the change force of the optical properties of the material when it is stressed, the sheet pile wall, the measurement of force, etc., can solve the problems that cannot truly reflect the force of the prestressed beam, etc. To achieve the effect that is beneficial to the scope of application, the stiffness and ultimate strength are small, and the stiffness and ultimate strength are large

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment provides an intelligent prestressed anchor plate;

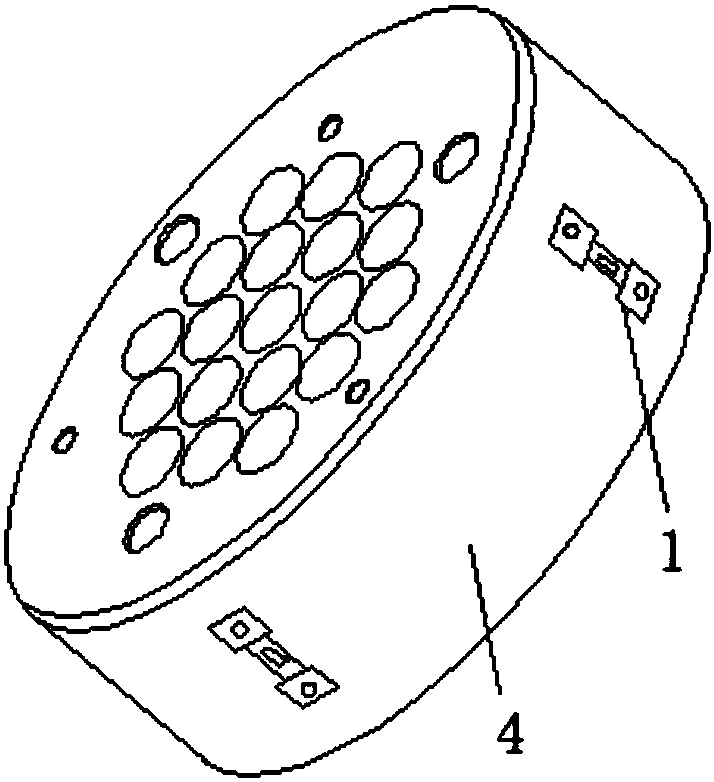

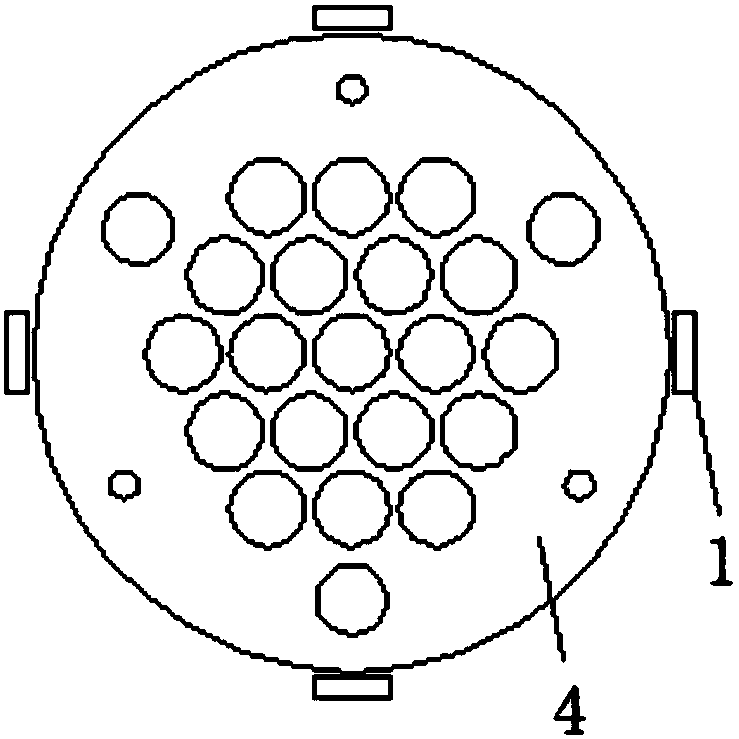

[0042] Such asfigure 1 and figure 2 As shown, the intelligent prestressed anchor plate in the present embodiment includes an anchor plate 4, and a plurality of strain sensors are arranged on the anchor plate 4, and the strain sensor includes a measurement section 1 that produces consistent deformation with the anchor plate and is located Sensitive element 2 on measuring section 1.

[0043] In the present invention, a plurality of strain sensors are arranged on the anchor plate, and the strain sensor includes a measuring section which produces consistent deformation with the anchor plate and a sensitive element arranged on the measuring section. After the prestressed bundle is anchored, all steel strands are stressed It will be transmitted to the prestressed anchor plate. After the integrated design of the strain sensor and the prestressed anchor plate, the prestressed anchor plate can be monitored to ...

Embodiment 2

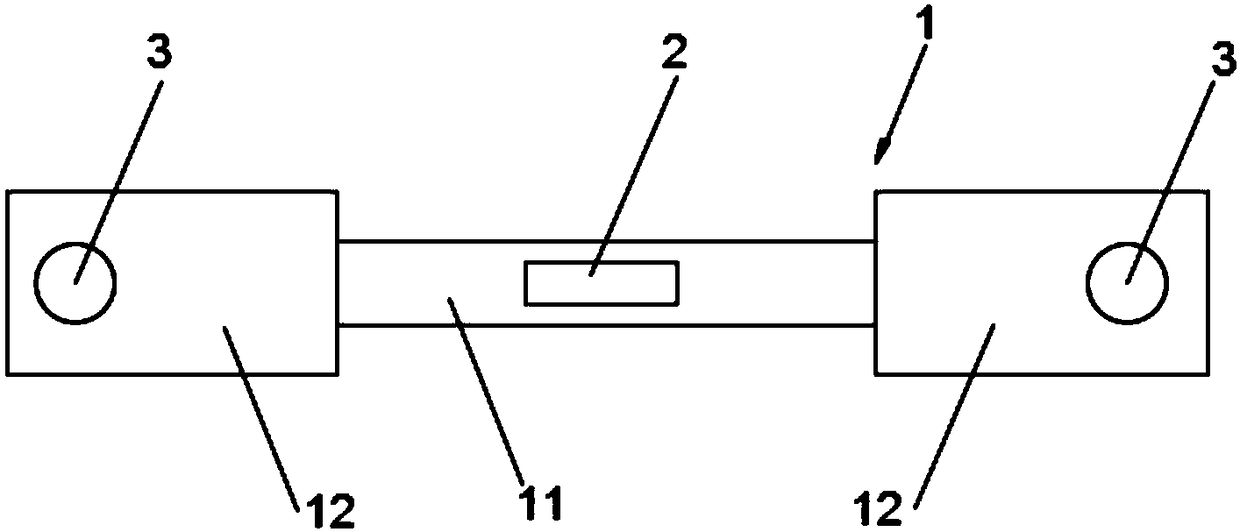

[0045] This embodiment provides a strain sensor;

[0046] The strain sensor in this embodiment includes a measuring section 1 that produces consistent deformation with the anchor plate and a sensitive element 2 that is arranged on the measuring section 1. The measuring section 1 includes a first measuring section 11 and a second measuring section 12. On the cross-section of the anchor plate in the force-bearing direction, the cross-sectional area of the first measuring section 11 is smaller than the cross-sectional area of the second measuring section 12 .

[0047] By setting the measurement section to include the first measurement section and the second measurement section, and on the section perpendicular to the force direction of the anchor plate, the cross-sectional area of the first measurement section is smaller than the cross-sectional area of the second measurement section, when the anchor plate occurs When deforming, the strains of the first measurement sectio...

Embodiment 3

[0059] This embodiment provides an intelligent prestressed anchor plate;

[0060] Such as Figure 1-Figure 3 As shown, the intelligent prestressed anchor plate in this embodiment includes an anchor plate 4, and the anchor plate is provided with a plurality of strain sensors, and the strain sensor includes a measurement section 1 that produces consistent deformation with the anchor plate 4 and is located on the Sensitive element 2 on measuring section 1.

[0061] In the present invention, a plurality of strain sensors are arranged on the anchor plate, and the strain sensor includes a measuring section which produces consistent deformation with the anchor plate and a sensitive element arranged on the measuring section. After the prestressed bundle is anchored, all steel strands are stressed It will be transmitted to the prestressed anchor plate. After the integrated design of the strain sensor and the prestressed anchor plate, the prestressed anchor plate can be monitored to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com